Upon accepting this job, I signed a non-disclosure agreement, so I unfortunately do not have any media to accompany my work description. I will explain the work I do as best as I can as a Mechanical Engineer for Foxconn Industrial Internet.

Overview:

As a Mechanical Engineer in Foxconn’s rapid prototyping division, I collaborate with clients and internal teams to design and manufacture network enclosure components and mechanical assemblies.

Key Responsibilities:

- Conduct design review meetings with clients to discuss functionality and manufacturability of enclosure components.

- Perform tolerance analysis, DFM reviews, and CAD modeling for sheet metal and plastic designs.

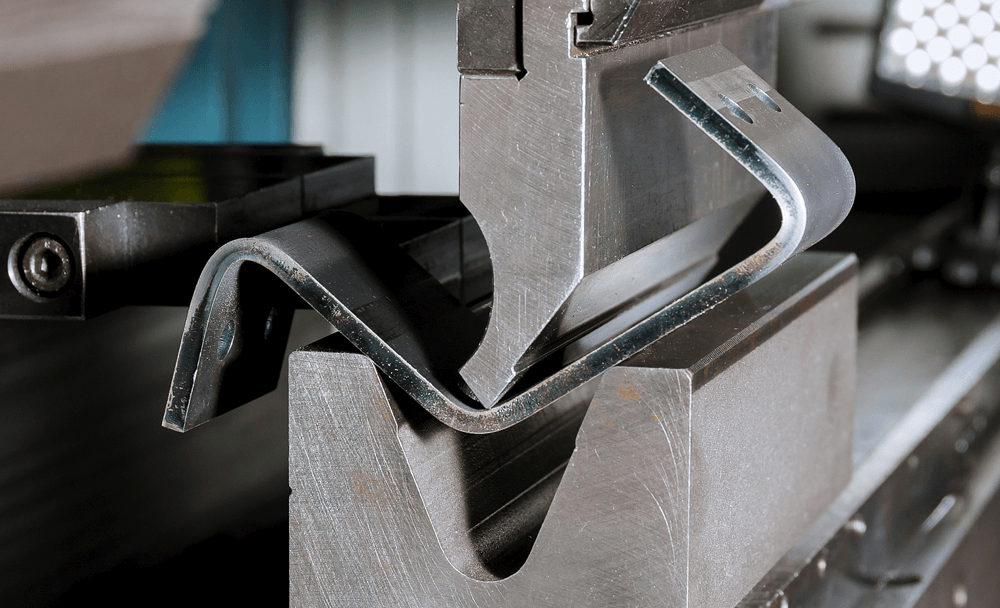

- Manage prototyping processes across Laser cutting, NCT, Punch Press, Press Brake, and manufacturing processes including CNC machining, die casting, plastic injection molding, 3D printing, and surface finishing.

- Execute cost analysis for low-volume fabrication and release updated drawings for production.

- Provide quality control oversight, hands-on engineering support, and troubleshooting during testing and validation.

- Collaborate with program managers to balance quality, cost, and lead time in supply chain logistics.

- Coordinate with overseas production teams working nights, improving project delivery timelines by 30%.

- Served as Liaison between global network companies and mass production team, providing deep and brief informational exchange.

Achievements:

- Maintained near 100% on-time delivery with minimal rework.

- Recognized by QC team for being highly hands-on and proactive in end-to-end processes.

- Praised by clients for professionalism, responsiveness, and technical expertise.

- Commended by project managers for my diligence and work ethic.