Goals

Frictional drag accounts for approximately 60% of a typical cargo ships propulsive power requirements. Air layer drag reduction is one technique that may enable significantly reducing a ship’s frictional resistance, and hence have a significant economic and environmental impact. To generate the air layer, instead of utilizing continuous slots to introduce the gas, use of discrete gas injection ports may be more advantageous.

Tasks

I was tasked to work in a team to design a hydrogen bubble generator using electrolysis through a 250V DC power supply with relays to probe bubble nucleation site on a platinum wire to visualize frictional flow. We tested with different types and length of wire to determine the ideal rate. Then, we used a 1kW photographic lamps to visualize flow speeds of 0.1 to 8m/s in tank, controlled by 2 potentiometers. We were still researching and testing so the timeline was insufficient for a complete product.

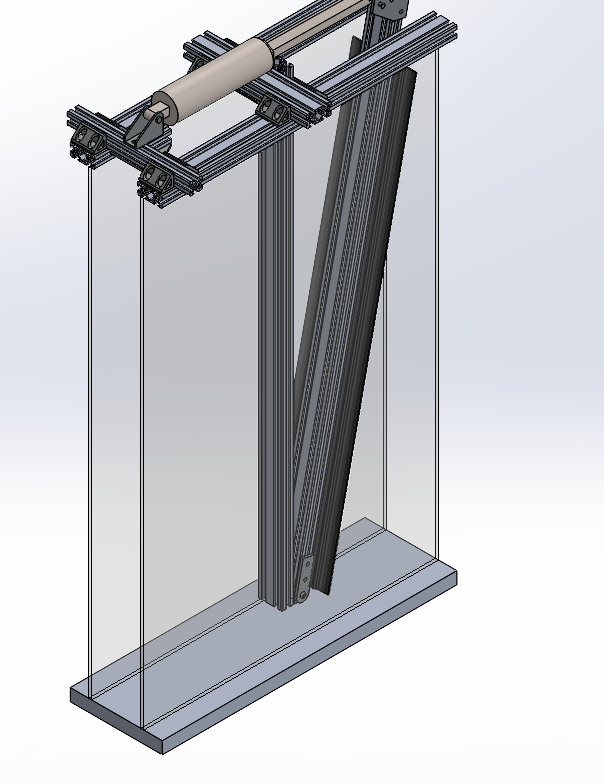

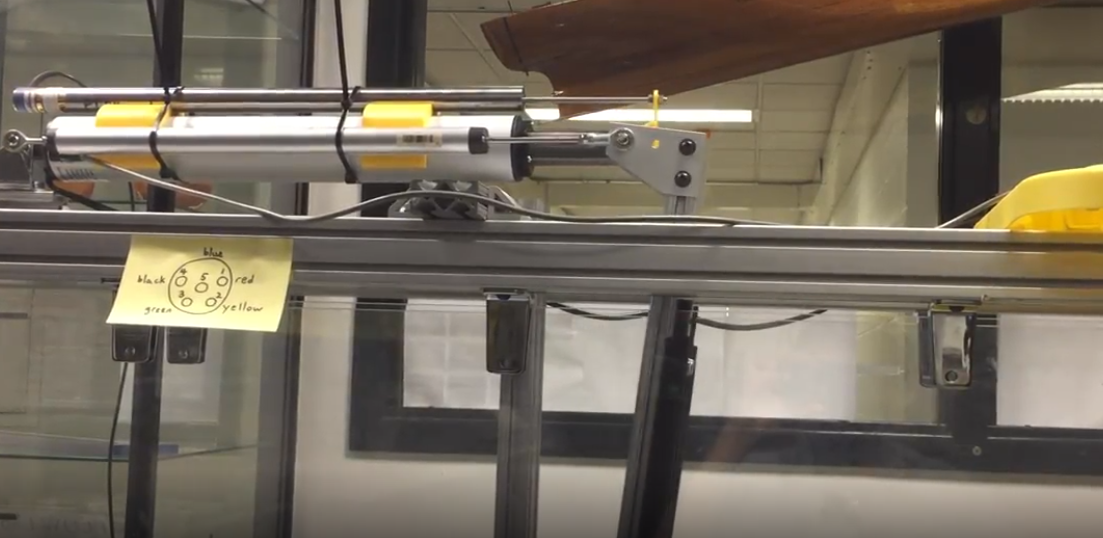

At the same time, I worked on fabricating a wave generator rig for testing. I assisted in using SolidWorks and analyzing CFD simulations for system modeling, integrating circuitry designing safety parameters.

Results

Assembly of testing rig using fabrication processes including machining of off-the-shelf components. Successful testing of wave generation at different speed and capacity and visualization of flow.

Fabrication of display tank