Goals

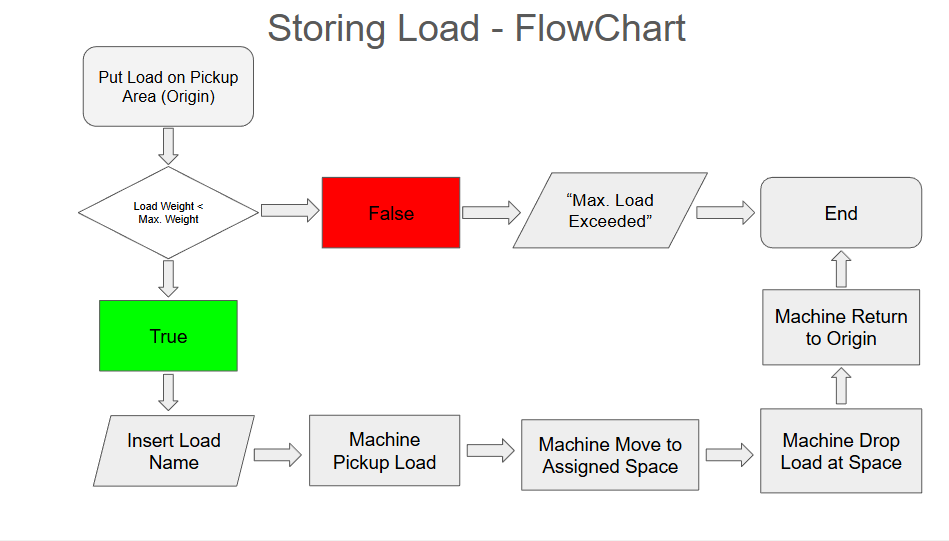

Automate commercial storage facilities using a smart robot to locate, organize, and store inventory efficiently and effectively to reduce the amount of used space and manual labor.

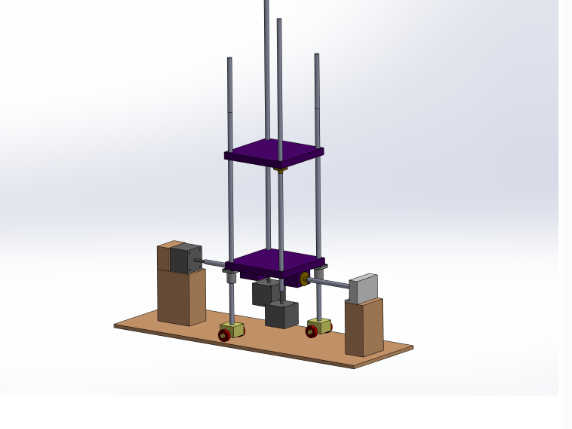

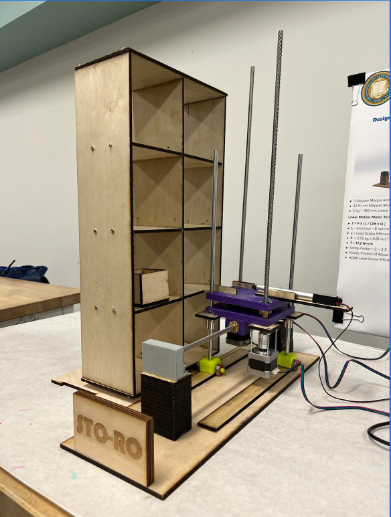

Concept Drawing

Components used

Hardware

- 3x Stepper Motors (42 N-cm)

- 1x Linear Actuator (2 kg – 100 mm)

- 3x 5mm to 8mm Shaft Couplers

- 2x Flanged linear bearing

- 2x X Tr8x8 500mm Lead Screws

- 1x X Tr8x8 350mm Lead Screw

- 2x 8mmx400mm Shafts

- 4x Tr8x8 Threaded Inserts

- 5x 8mmx22mmx7mm Bearings

- Various Screws and Nut

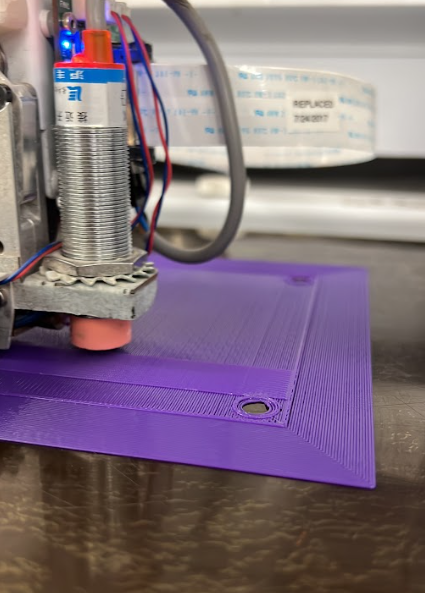

Custom Parts

- 3D Printing with PLA

- Bottom & Top Main Platforms

- Horizontal Lead Screw Support

- Pillow Block Bearing Housing

- Wheel Support

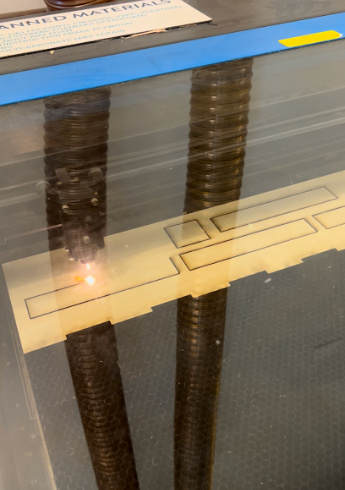

- Laser Cutting with Plywood

- Base Platform

- Linear Actuator Housing & Guide

- 508 mm x 254 mm x 127 mm Shelf

- Horizontal Bearing & Stepper Motor Base

- Vertical Stepper Motor & Flange Linear Bearing Support

Circuit

- 1x Circuit Breadboard

- 2x A4988 Motor Drivers

- 2x 5v Relays

- 2x 47 µF Capacitors

- 1x Linear Actuator

- 3x NEMA 17 Stepper Motors

- 1x ESP32

- 12V Power Supply

Final Product

Successfully built a functioning prototype of our concept, capable of transporting 15lb loads to designated slots with ±0.2 mm

positioning accuracy. However, many limitations still apply.