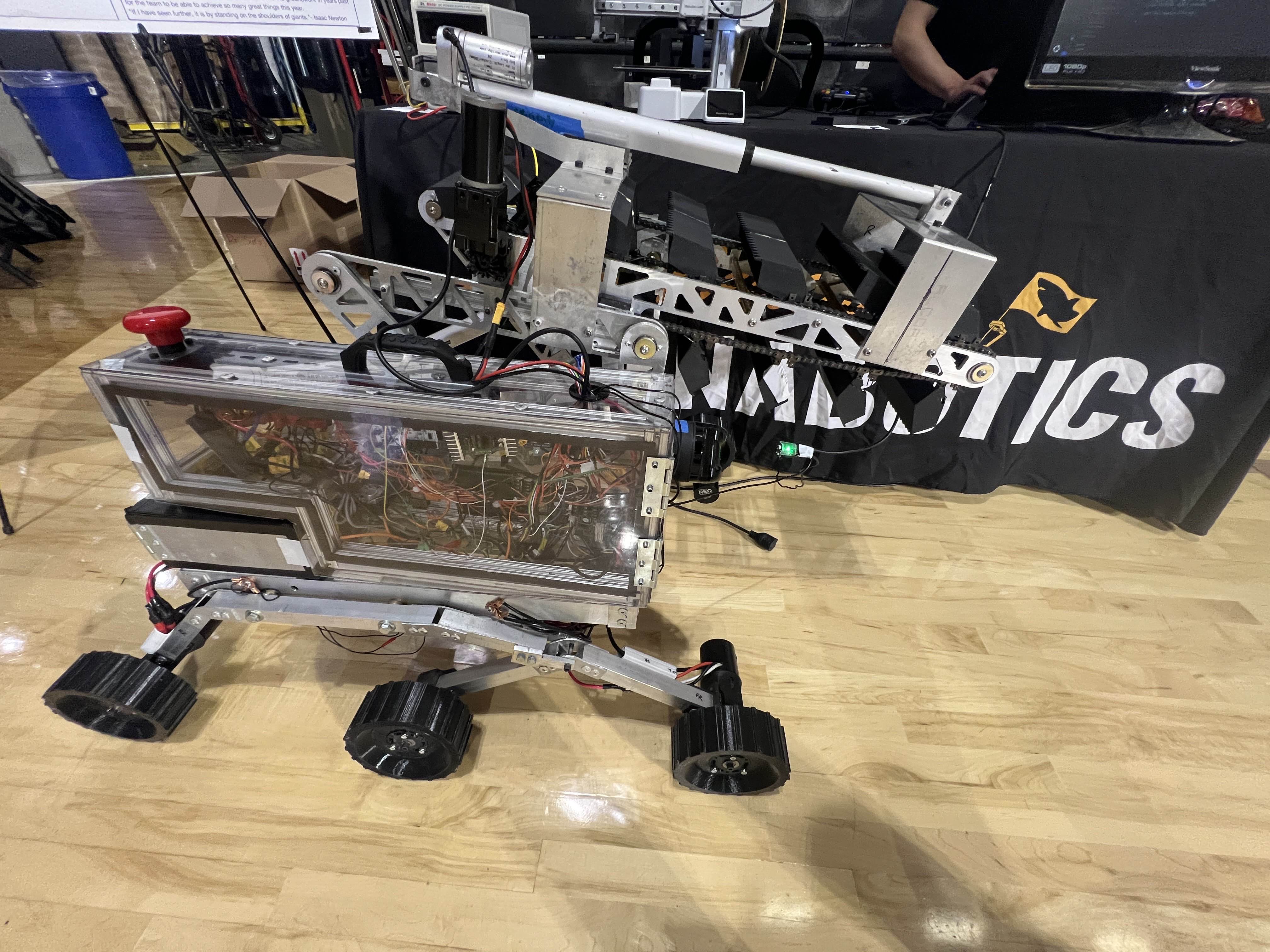

This project is a full mechanical development effort for our NASA Lunabotics rover. I served as the Mechanical Co Lead and carried responsibility for both system design and hands on fabrication. My main focus throughout the season was the bucket ladder excavator, which became the most mechanically involved subsystem on the entire rover. The excavator needed to deploy smoothly, withstand digging forces, and interface cleanly with the drivetrain and chassis. Because of that, I spent a significant amount of time modeling linkage behavior, refining geometries, and making sure every part of the mechanism could survive real excavation conditions

The excavator went through many iterations, and I led the design work for all of them. I created the four bar linkage model from the ground up and tuned the actuator stroke, pivot placements, and linkage lengths until the deployment motion produced the angle and reach we needed inside the regolith bed. I also designed the sprocket and chain system that moves the buckets. This included setting spacing and tension, aligning the mounting features, and ensuring the system could be manufactured with the tools available to our team. Most of the CAD for this subsystem, including the rail guided lowering system and bucket arrangement, came directly from my work.

A major portion of my contribution involved manufacturing and physical assembly. I machined aluminum frame components, drilled and tapped mounting locations, cut and shaped brackets, and test fitted mechanical parts long before the full rover existed. Whenever something in the real hardware did not perfectly match how it behaved in the CAD model, I was usually the one diagnosing tolerances, correcting fits, or modifying parts so the system would operate consistently. Through this process I eliminated binding in the linkage, corrected sprocket alignment issues, and improved the reliability of the entire deployment system.

As the rover came together, I worked closely with both the drivetrain and electrical teams to ensure that the excavator did not interfere with sensors, wiring, structural members, or the chassis architecture. Integration required constant adjustment. Sometimes that meant shifting a mounting point, adding a spacer, or updating a bracket so every subsystem could coexist. This collaboration helped the excavator work seamlessly with the rest of the rover instead of acting as an isolated mechanism.

By the time we reached our Critical Design Review, the excavator was one of the most mature and well justified systems on the robot. I presented the mechanical reasoning for the design, walked through its deployment behavior, and explained our manufacturing plan based on the hands on work already completed in the shop. The review confirmed that our approach was solid and allowed us to move confidently into full manufacturing.

This project represents the complete mechanical design cycle, from concept development and CAD modeling to machining, assembly, troubleshooting, and final system integration. The pictures you place here will show both the finished rover and the detailed work behind its construction.