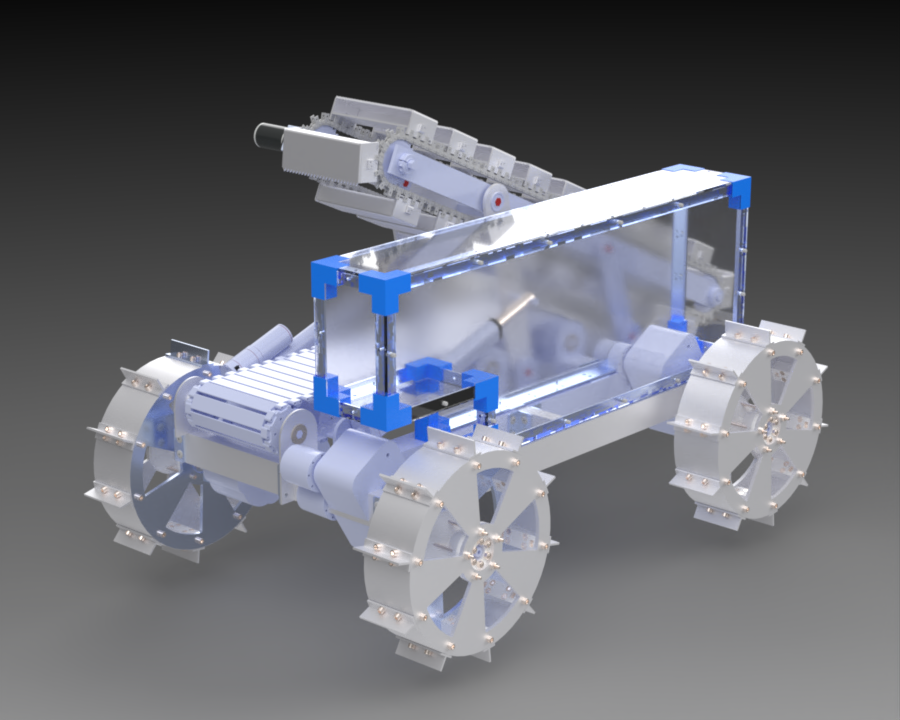

Long Beach Lunabotics is California State University Long Beach’s official team that competes in NASA’s Lunabotics Challenge, a national robotics competition held at Kennedy Space Center. The challenge involves designing and building a rover capable of excavating and depositing simulated lunar soil, mimicking future Moon base construction. As Mechanical Lead for the 2024 to 2025 and 2025 to 2026 seasons, I was responsible for overseeing the design and fabrication of the rover’s mechanical systems while ensuring everything stayed practical for manufacturing and testing. My main focus was keeping the design simple, reliable, and easy to assemble so our team could spend more time testing instead of troubleshooting overly complex systems. I spent a lot of time in SOLIDWORKS modeling the frame, drivetrain, and excavation systems while teaching my members how to design efficiently and run simulations. I worked alongside them to check dimensions, run stress analyses, and make sure the rover stayed within NASA’s weight and size limits. Here is this years CAD:

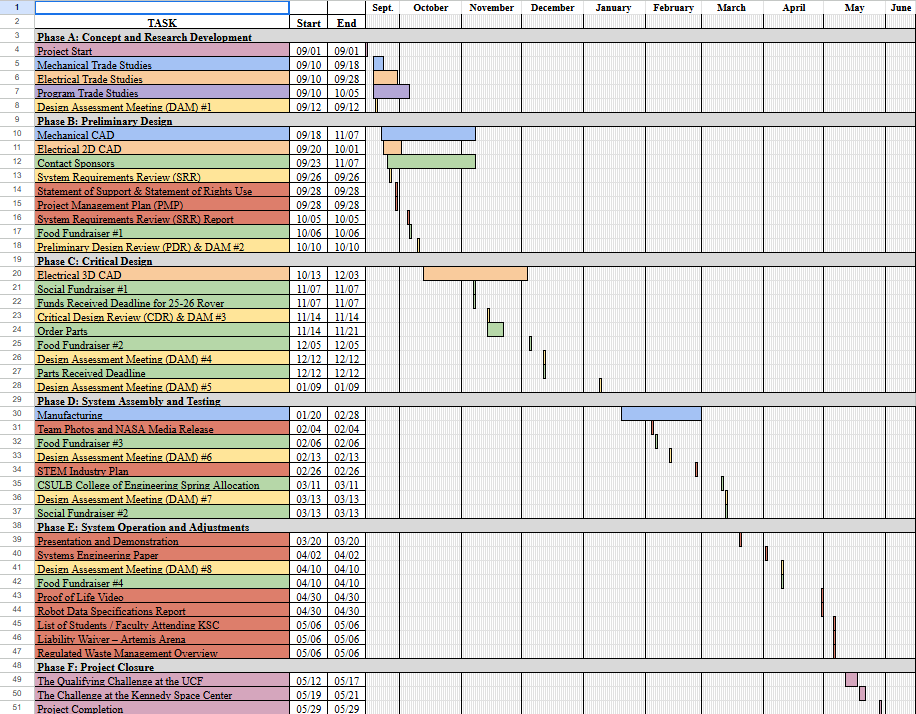

A big part of my role was working closely with the electrical and programming teams to make sure all subsystems fit together properly. I had to design and CAD mounting points for components like PCB, sensors, and wiring, thinking ahead about how the rover would be wired and accessed during testing. Communication between subsystems was constant, especially during integration where small mechanical changes could affect electrical layouts. I also helped lead machining and assembly in the shop, making sure every part we built fit correctly and was safe to operate. Outside of design I participated in project management meetings, reviewed progress at each design milestone, and helped prepare for major NASA review submissions. This is our Gantt chart which outlines the schedule and development phases for the rover and I will include the image here.

Overall being part of Long Beach Lunabotics taught me how to approach large multidisciplinary projects like a real engineering team balancing design work collaboration deadlines and hands-on fabrication. It was a full cycle experience from concept sketches and CAD to machining and system testing and it pushed me to think not just about how to design a part but how every decision affects the rover as a whole.

For more detailed view check out the CDR slides in attachments