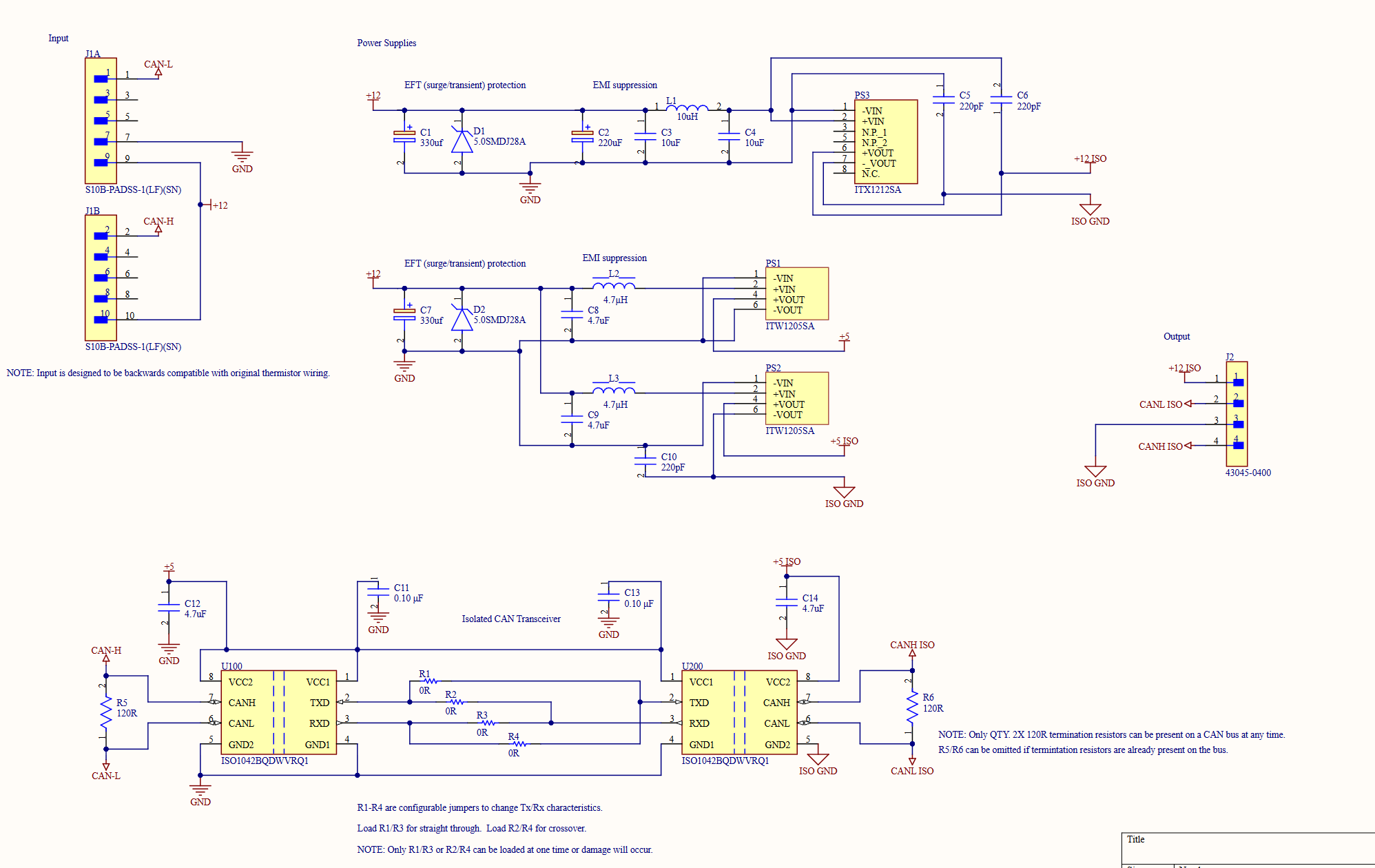

In May 2025, we noticed that the temperature sensors on our 324V battery would enter a fault state when the motor was spinning. Through isolating the temperature sensors, we determined this was a symptom of a larger problem. The sensor's 5V line had about 40V peak-to-peak of noise on it at 8kHz. This was indicative of noise on the low-voltage bus from the inverter coupling into the rest of the system.

Image of the 12V Bus measured with a differential probe:

Throughout the summer, a series of band-aid fixes were implemented, which did not resolve the root of the issue. In August, development of the Temperature Sensor Isolation Board was started to improve the power going into the power supply under 5V peak to peak.

Temperature Sensor Isolation Board V1 Schematic:

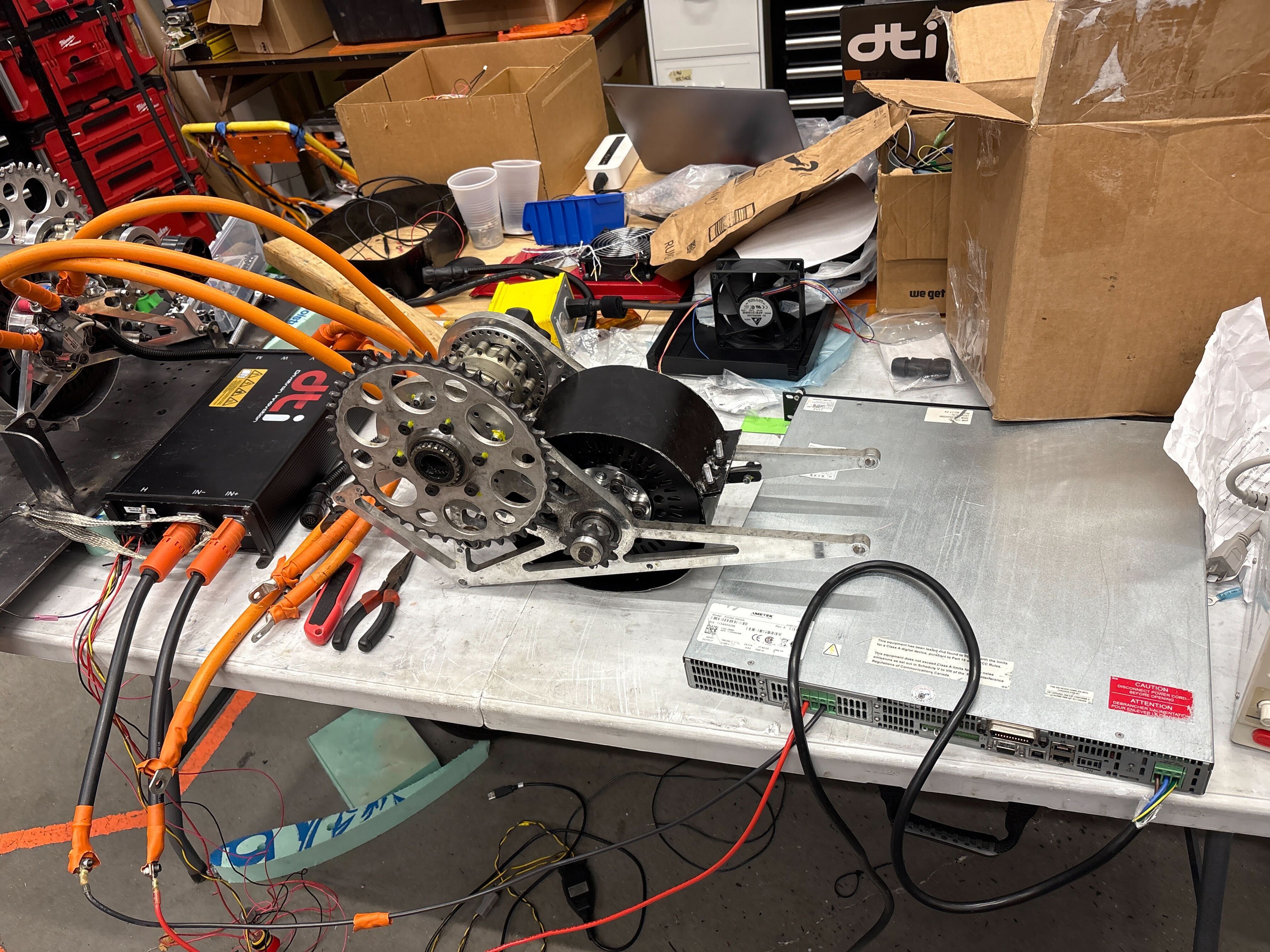

While I oversaw the development of the Temperature Sensor Isolation Board, I started designing a series of tests to undertake on the powertrain outside of the car.

Test Bench Schematic:

Test Bench Photo:

I ran up to 15 tests to slowly eliminate noise variables. Key findings:

- Low-voltage wire lengths do not affect the amount of noise in the system.

- Shielding cables does not affect the amount of noise in this setting

- Removing the grounding strap reduces noise to 10 V peak-to-peak.

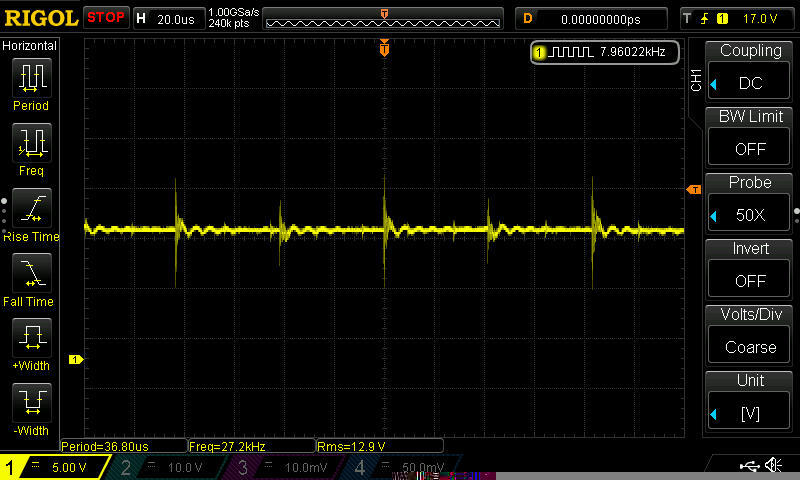

Determined that the inverter layout itself was most likely causing problems. We bought a used inverter (Cascadia PM100DX) and integrated it into our system.

With the new inverter, the noise in the system and a common mode choke, noise was at an acceptable level:

:

:

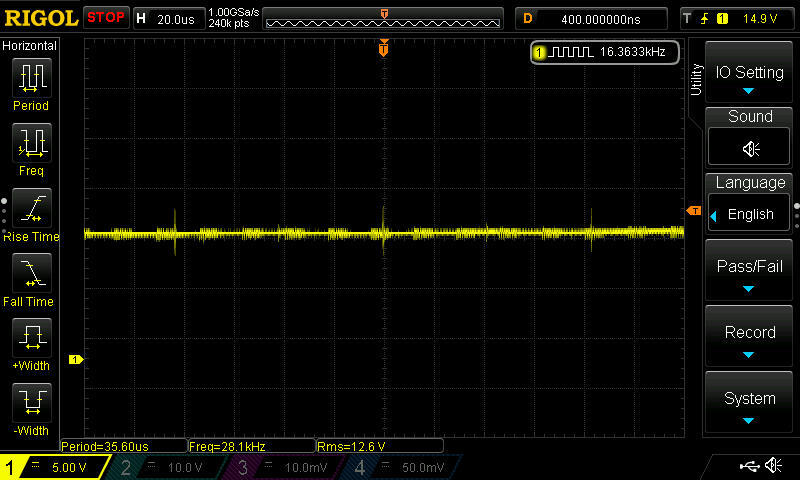

With the Temperature Sensor Isolation Board, the signal was cleaned up even further:

With these two results, we can integrate everything back into the car and conduct further testing with the Tractive Battery.