📌 Project Overview

Designed, analyzed, fabricated, and validated a tadpole-configuration Electric Human Powered Vehicle (EHPVC) for the ASME E-FX Competition. The vehicle integrated pedal-powered dynamics with an auxiliary electric drive system, developed to meet performance, manufacturability, and competition constraints.

👤 Role & Responsibilities

- Team Captain, Design Lead, and Fabrication Lead – responsible for complete CAD modeling, structural and aerodynamic analysis, and leading the chassis fabrication.

- Coordinated team efforts across design, welding, sourcing, and integration of power systems and drivetrain.

🖥️ Design & CAD Development

-

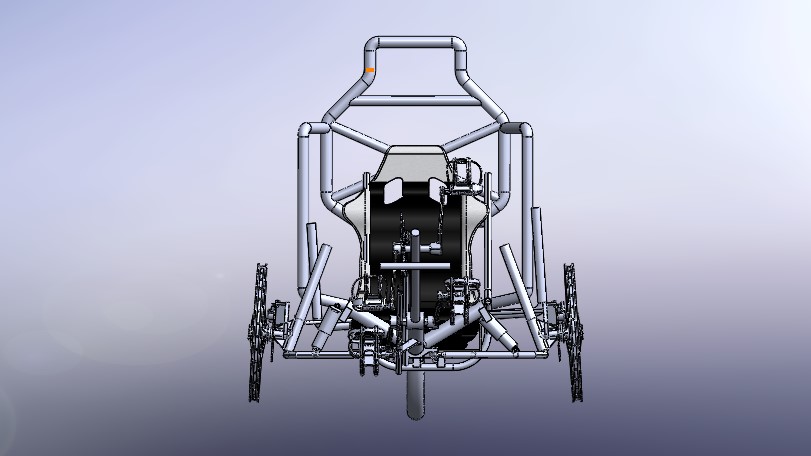

Modeled the entire vehicle using SolidWorks, incorporating ergonomic considerations, RPS (Roll Protection System), and tadpole (two front wheels + one rear) geometry.

-

Integrated a 500W hub motor on the rear wheel and a 13,000 mAh battery pack to support hybrid human-electric operation.

-

Balanced stability, ground clearance, and weight distribution to optimize handling.

⚙️ Finite Element Analysis (FEA)

-

Conducted structural FEA on the chassis and Roll Protection System (RPS).

-

Minimum required load capacity: 2800 N | Achieved: >5000 N, ensuring compliance with competition safety factors.

-

Optimized weld joints and tubing curvature to align fabricated structure with FEA predictions.

🌬️ Computational Fluid Dynamics (CFD)

-

Performed aerodynamic simulations to analyze drag and lift characteristics.

-

Results: Lift coefficient (Cl) = 0.1, Drag coefficient (Cd) = 4.69.

-

Proposed addition of a front windshield for drag reduction, but implementation was constrained by time.

🛠️ Fabrication

-

Led fabrication activities including welding of the chassis and RPS, ensuring geometrical accuracy for structural integrity.

-

Outsourced critical drivetrain and rolling components (wheels, chain, crankset, etc.) from bicycle suppliers.

-

Key challenge: achieving precise weld curvature on the RPS to preserve FEA-validated load paths.

🔋 Testing & Validation

-

Conducted trials for battery consumption, charging cycles, and drivetrain dynamics.

-

Identified practical issues such as chain slack, DFM-related adjustments, and ride stability vs. ground clearance.

-

Despite minor operational inefficiencies, the vehicle successfully met competition criteria.

🏆 Outcome & Achievements

-

Secured 1st Place in the ASME E-FX Competition.

-

Validated complete product development cycle: CAD modeling → FEA/CFD → fabrication → testing.

-

Gained hands-on expertise in DFM, vehicle dynamics, drivetrain integration, and structural welding practices.

--

.png)