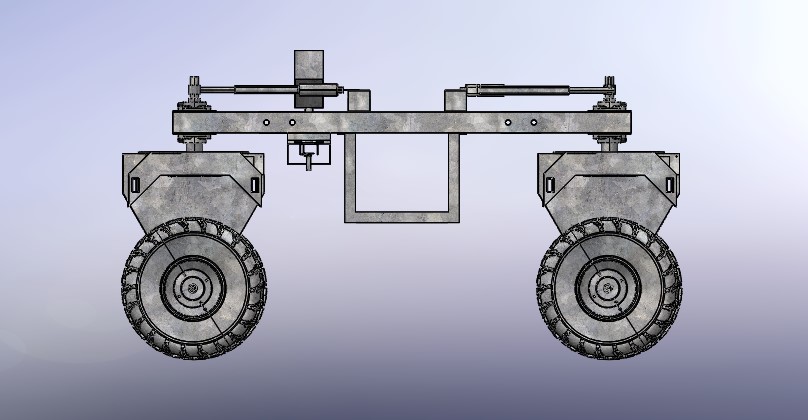

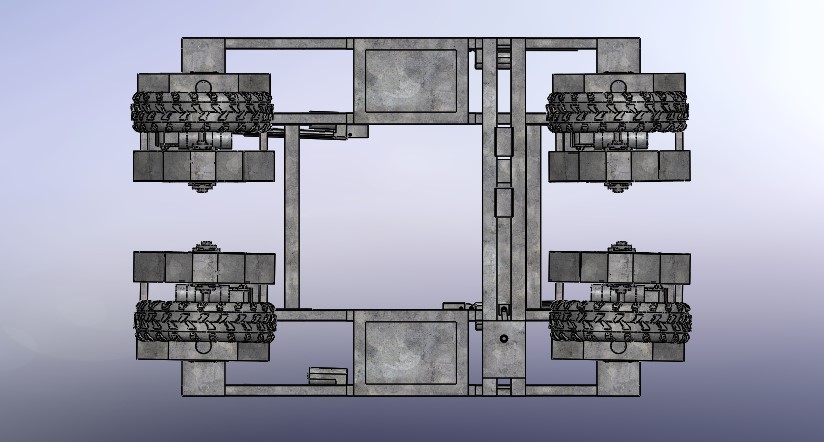

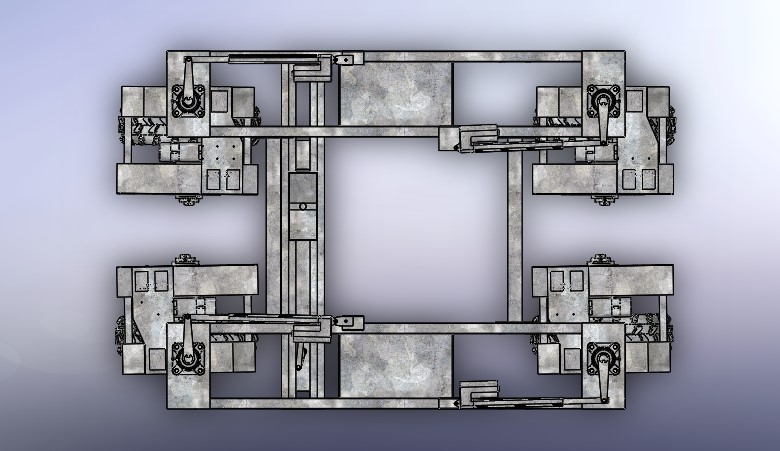

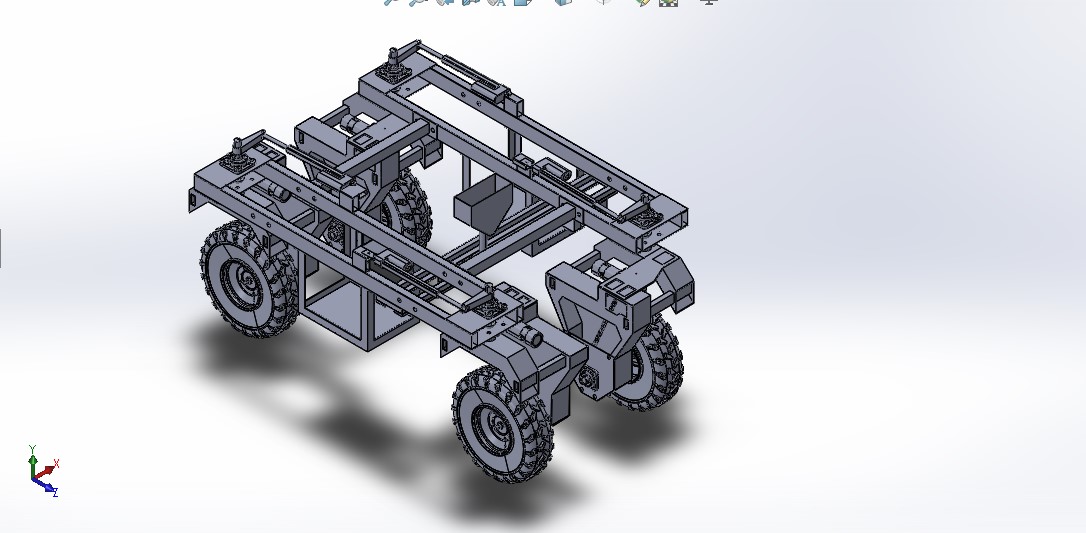

The Field Seeder System Vehicle was developed to address the need for efficient and reliable seed planting solutions across variable terrains. The project focused on reverse engineering a conventional precision seeder and redesigning it into a validated CAD model with enhanced functionality and manufacturability. Core objectives included optimizing the chassis, suspension geometry, and depth-control mechanisms to improve performance in uneven field conditions.

This work combined design-for-manufacturing (DFM) principles with tolerance and clearance validation, ensuring the system could be fabricated using CNC machining, welding, and modular assembly techniques. By integrating mechanical optimization with robust design validation, the project delivered a scalable and field-ready seeder system capable of supporting modern agricultural operations.