Objective

The goal was to design a master-slave control system capable of amplifying user input force while maintaining real-time position tracking between two brushed DC motors. The system was intended to replicate the motion of the master unit through the slave motor with high precision and low latency.

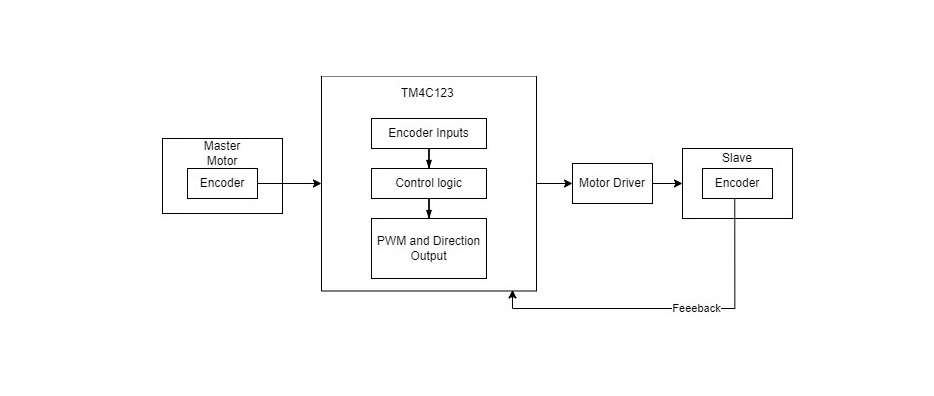

System Design

The control architecture relied on two TM4C123 microcontrollers — one for the master unit and one for the slave.

- Master side: Captured position via potentiometer and transmitted it digitally.

- Slave side: Received target position, compared it to local feedback, and applied a PD controller to drive the actuator.

Communication and debugging were performed through UART at 9600 baud, and PWM signals controlled motor speed and direction.

Control Strategy

A PD controller was implemented for accurate and stable motion replication:

- 𝐾𝑝 = 60, 𝐾𝑑 = 5

- Achieved quick response with minimal overshoot

- Excluded 𝐾𝑖 to avoid integrator wind-up and simplify tuning.

Implementation

The implementation involved:

- Hardware: TM4C123 LaunchPad, brushed DC motors, potentiometers, and H-bridge driver (TA7267BP).

- Software: Developed in TI Code Composer Studio using TivaWare library.

- Communication: UART used to display desired and actual positions for real-time validation.

Testing confirmed the system could replicate movements with high accuracy and maintain update rates above 10 Hz.

Challenges

- Tuning PD parameters for the right balance between stability and responsiveness.

- Managing electrical noise in potentiometer readings.

- Meeting real-time constraints with limited computational resources.

Results

- Successfully achieved real-time, low-latency performance.

- The slave motor followed master motion accurately with minimal lag.

- Demonstrated robustness and repeatability during final demo.

Future Improvements

- Incorporate wireless communication between units.

- Expand to multi-DOF robotic arms.

- Implement adaptive or model-based control for greater accuracy.

#include <stdint.h>

#include <stdbool.h>

#include <stdlib.h>

#include <string.h>

#include "hw_memmap.h"

#include "hw_types.h"

#include "hw_gpio.h"

#include "sysctl.h"

#include "gpio.h"

#include "pwm.h"

#include "pin_map.h"

#include "adc.h"

#include "uart.h"

// Define the PWM frequency

#define PWM_FREQUENCY 1000

// PID controller constants

#define KP 60.0 // Proportional gain

#define KI 0.0 // Integral gain

#define KD 5.0 // Derivative gain

int32_t constraintValue = 15000;

// Global variables for PID control

int32_t previousError = 0; // Previous error value for derivative calculation

int32_t integral = 0; // Integral term for PID control

void UART0_Init(void) {

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

GPIOPinConfigure(GPIO_PA0_U0RX);

GPIOPinConfigure(GPIO_PA1_U0TX);

GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

UARTConfigSetExpClk(UART0_BASE, SysCtlClockGet(), 115200,

(UART_CONFIG_WLEN_8 | UART_CONFIG_STOP_ONE |

UART_CONFIG_PAR_NONE));

UARTEnable(UART0_BASE);

}

void UART0_SendString(const char *str) {

while (*str) {

UARTCharPut(UART0_BASE, *str++);

}

}

void UART0_SendInt(int32_t value) {

char buffer[12]; // Buffer to hold the string representation of the integer

itoa(value, buffer, 10); // Convert integer to string

UART0_SendString(buffer); // Send the string via UART

}

void itoa(int value, char* buffer, int base) {

char *ptr = buffer, *ptr1 = buffer, tmp_char;

int tmp_value;

if (base < 2 || base > 36) { *buffer = '\0'; return; }

do {

tmp_value = value;

value /= base;

*ptr++ = "zyxwvutsrqponmlkjihgfedcba9876543210123456789abcdefghijklmnopqrstuvwxyz"[35 +

(tmp_value - value * base)];

} while ( value );

// Apply negative sign

if (tmp_value < 0) *ptr++ = '-';

*ptr-- = '\0';

while (ptr1 < ptr) {

tmp_char = *ptr;

*ptr-- = *ptr1;

*ptr1++ = tmp_char;

}

}

// Function to initialize system clock, GPIO, PWM, and ADC

void setup() {

// Set the system clock to 50 MHz

SysCtlClockSet(SYSCTL_SYSDIV_4 | SYSCTL_USE_PLL | SYSCTL_OSC_MAIN | SYSCTL_XTAL_16MHZ);

UART0_Init();

UART0_SendString("UART Initialized.\r\n");

// Enable peripherals for GPIO, PWM, and ADC

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA); // Enable GPIO Port A

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB); // Enable GPIO Port B

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE); // Enable GPIO Port E

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOF); // Enable GPIO Port F

SysCtlPeripheralEnable(SYSCTL_PERIPH_PWM1); // Enable PWM1 module

SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0); // Enable ADC0 module

// Wait for peripherals to be ready

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_GPIOA)); // Wait for GPIO Port A to be ready

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_GPIOB)); // Wait for GPIO Port B to be ready

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_GPIOE)); // Wait for GPIO Port E to be ready

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_GPIOF)); // Wait for GPIO Port F to be ready

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_PWM1)); // Wait for PWM1 module to be ready

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_ADC0)); // Wait for ADC0 module to be ready

UART0_SendString("Peripherals Enabled.\r\n");

// Unlock PF0 and PF4 for switch usage

HWREG(GPIO_PORTF_BASE + GPIO_O_LOCK) = GPIO_LOCK_KEY;

HWREG(GPIO_PORTF_BASE + GPIO_O_CR) |= GPIO_PIN_0 | GPIO_PIN_4;

HWREG(GPIO_PORTF_BASE + GPIO_O_LOCK) = 0;

// Configure GPIO for switch (PF4) and magnet control (PB2)

GPIOPinTypeGPIOInput(GPIO_PORTF_BASE, GPIO_PIN_4); // Configure PF4 as input (switch)

GPIOPadConfigSet(GPIO_PORTF_BASE, GPIO_PIN_4, GPIO_STRENGTH_2MA,

GPIO_PIN_TYPE_STD_WPU); // Enable weak pull-up resistor on PF4

GPIOPinTypeGPIOOutput(GPIO_PORTB_BASE, GPIO_PIN_2); // Configure PB2 as output (magnet

control)

// Initialize PB2 to low

GPIOPinWrite(GPIO_PORTB_BASE, GPIO_PIN_2, 0);

// Configure PWM

GPIOPinTypePWM(GPIO_PORTE_BASE, GPIO_PIN_4 | GPIO_PIN_5); // Configure PE4 and PE5 as

PWM output

GPIOPinConfigure(GPIO_PE4_M1PWM2); // Map PE4 to M1PWM2

GPIOPinConfigure(GPIO_PE5_M1PWM3); // Map PE5 to M1PWM3

PWMGenConfigure(PWM1_BASE, PWM_GEN_1, PWM_GEN_MODE_DOWN |

PWM_GEN_MODE_NO_SYNC); // Configure PWM generator 1

uint32_t pwmPeriod = SysCtlClockGet() / PWM_FREQUENCY;

PWMGenPeriodSet(PWM1_BASE, PWM_GEN_1, pwmPeriod); // Set PWM period based on system

clock

PWMPulseWidthSet(PWM1_BASE, PWM_OUT_2, 0); // Initialize PWM pulse width for PE4 to 0

PWMPulseWidthSet(PWM1_BASE, PWM_OUT_3, 0); // Initialize PWM pulse width for PE5 to 0

PWMOutputState(PWM1_BASE, PWM_OUT_2_BIT | PWM_OUT_3_BIT, true); // Enable PWM

output on PE4 and PE5

PWMGenEnable(PWM1_BASE, PWM_GEN_1); // Enable PWM generator 1

UART0_SendString("PWM Initialized.\r\n");

// Configure GPIO for motor direction

GPIOPinTypeGPIOOutput(GPIO_PORTA_BASE, GPIO_PIN_2 | GPIO_PIN_3); // Configure PA2 and

PA3 as output

// Configure ADC for master potentiometer (PE3) and slave potentiometer (PE2)

ADCSequenceConfigure(ADC0_BASE, 3, ADC_TRIGGER_PROCESSOR, 0); // Configure ADC sequence 3

ADCSequenceStepConfigure(ADC0_BASE, 3, 0, ADC_CTL_CH0 | ADC_CTL_IE | ADC_CTL_END); //

Configure ADC steps for master potentiometer

ADCSequenceEnable(ADC0_BASE, 3); // Enable ADC sequence 3

ADCIntClear(ADC0_BASE, 3); // Clear ADC interrupt flag for sequence 3

ADCSequenceConfigure(ADC0_BASE, 2, ADC_TRIGGER_PROCESSOR, 0); // Configure ADC sequence 2

ADCSequenceStepConfigure(ADC0_BASE, 2, 0, ADC_CTL_CH1 | ADC_CTL_IE | ADC_CTL_END); //

Configure ADC steps for slave potentiometer

ADCSequenceEnable(ADC0_BASE, 2); // Enable ADC sequence 2

ADCIntClear(ADC0_BASE, 2); // Clear ADC interrupt flag for sequence 2

UART0_SendString("ADC Initialized.\r\n");

}

// Function to read ADC value from a given sequence

uint32_t readADC(uint32_t base, uint32_t sequence) {

ADCProcessorTrigger(base, sequence); // Trigger ADC conversion

while(!ADCIntStatus(base, sequence, false)); // Wait for ADC conversion to complete

uint32_t value; // Variable to store ADC result

ADCSequenceDataGet(base, sequence, &value); // Retrieve ADC result

ADCIntClear(base, sequence); // Clear ADC interrupt flag

return value; // Return ADC result

}

// PID control function

int32_t pidControl(int32_t setpoint, int32_t measuredValue) {

int32_t error = setpoint - measuredValue; // Calculate the error

integral += error; // Update integral term

int32_t derivative = error - previousError; // Calculate derivative term

previousError = error; // Update previous error

int32_t output = (int32_t)(KP * error + KI * integral + KD * derivative); // Calculate PID output

if (output >= constraintValue)

{

output = constraintValue;

}else if (output <=-constraintValue)

{

output =-constraintValue;

}

return output; // Return PID output

}

void handleSwitchAndMagnet() {

static bool magnetState = false; // Initial state of the magnet (off)

static bool previousSwitchState = true; // Initial state of the switch (not pressed)

// Read current switch state

bool currentSwitchState = GPIOPinRead(GPIO_PORTF_BASE, GPIO_PIN_4) == 0;

// Toggle magnet state when switch is pressed

if (currentSwitchState && !previousSwitchState) {

magnetState = !magnetState;

GPIOPinWrite(GPIO_PORTB_BASE, GPIO_PIN_2, magnetState ? GPIO_PIN_2 : 0);

}

// Update previous switch state

previousSwitchState = currentSwitchState;

}

int main() {

setup(); // Call setup function to initialize hardware

uint32_t pwmPeriod = SysCtlClockGet() / PWM_FREQUENCY;

while (1) { // Main loop

// Read desired position from master potentiometer (PE3)

int32_t desiredPosition = readADC(ADC0_BASE, 3)+260;

//UART0_SendString("Desired Position: ");

//UART0_SendInt(desiredPosition); // Send desired position value

//UART0_SendString("\r\n");

// Read actual position from slave potentiometer (PE2)

int32_t actualPosition = readADC(ADC0_BASE, 2);

//UART0_SendString("Actual Position: ");

//UART0_SendInt(actualPosition); // Send actual position value

//UART0_SendString("\r\n");

// Calculate control signal using PID control

int32_t controlSignal = pidControl(desiredPosition, actualPosition);

//UART0_SendString("Control Signal: ");

//UART0_SendInt(controlSignal); // Send control signal value

//UART0_SendString("\r\n");

// Set motor direction and PWM signals based on control signal

if (controlSignal > 0) {

GPIOPinWrite(GPIO_PORTA_BASE, GPIO_PIN_2, GPIO_PIN_2); // Set direction forward

GPIOPinWrite(GPIO_PORTA_BASE, GPIO_PIN_3, 0); // Clear reverse direction pin

PWMPulseWidthSet(PWM1_BASE, PWM_OUT_2, 50000 - abs(controlSignal)); // Set PWM duty

cycle for forward direction

PWMPulseWidthSet(PWM1_BASE, PWM_OUT_3, 0); // Clear PWM duty cycle for reverse

direction

} else {

GPIOPinWrite(GPIO_PORTA_BASE, GPIO_PIN_2, 0); // Clear forward direction pin

GPIOPinWrite(GPIO_PORTA_BASE, GPIO_PIN_3, GPIO_PIN_3); // Set direction reverse

PWMPulseWidthSet(PWM1_BASE, PWM_OUT_2, 0); // Clear PWM duty cycle for forward

direction

PWMPulseWidthSet(PWM1_BASE, PWM_OUT_3, 50000 - abs(controlSignal)); // Set PWM duty

cycle for reverse direction

}

handleSwitchAndMagnet(); // Handle switch and magnet control

// Send debug information via UART

UART0_SendString("Master Position: ");

UART0_SendInt(desiredPosition);

UART0_SendString(", Slave Position: ");

UART0_SendInt(actualPosition);

UART0_SendString(", Control Signal: ");

UART0_SendInt(controlSignal);

UART0_SendString("\r\n");

//UART0_SendString(", Magnet State: ");

}

}