Shopping Cart Design

This project involved the full-cycle development of a novel, open-source compliant shopping cart, initiated to explore advanced applications of mechanical design, analysis, and fabrication. The core objective was to apply modern engineering methods to create a robust and functional solution suitable for public use, while maintaining detailed documentation for community replication.

The engineering process focused heavily on ensuring structural integrity and user safety:

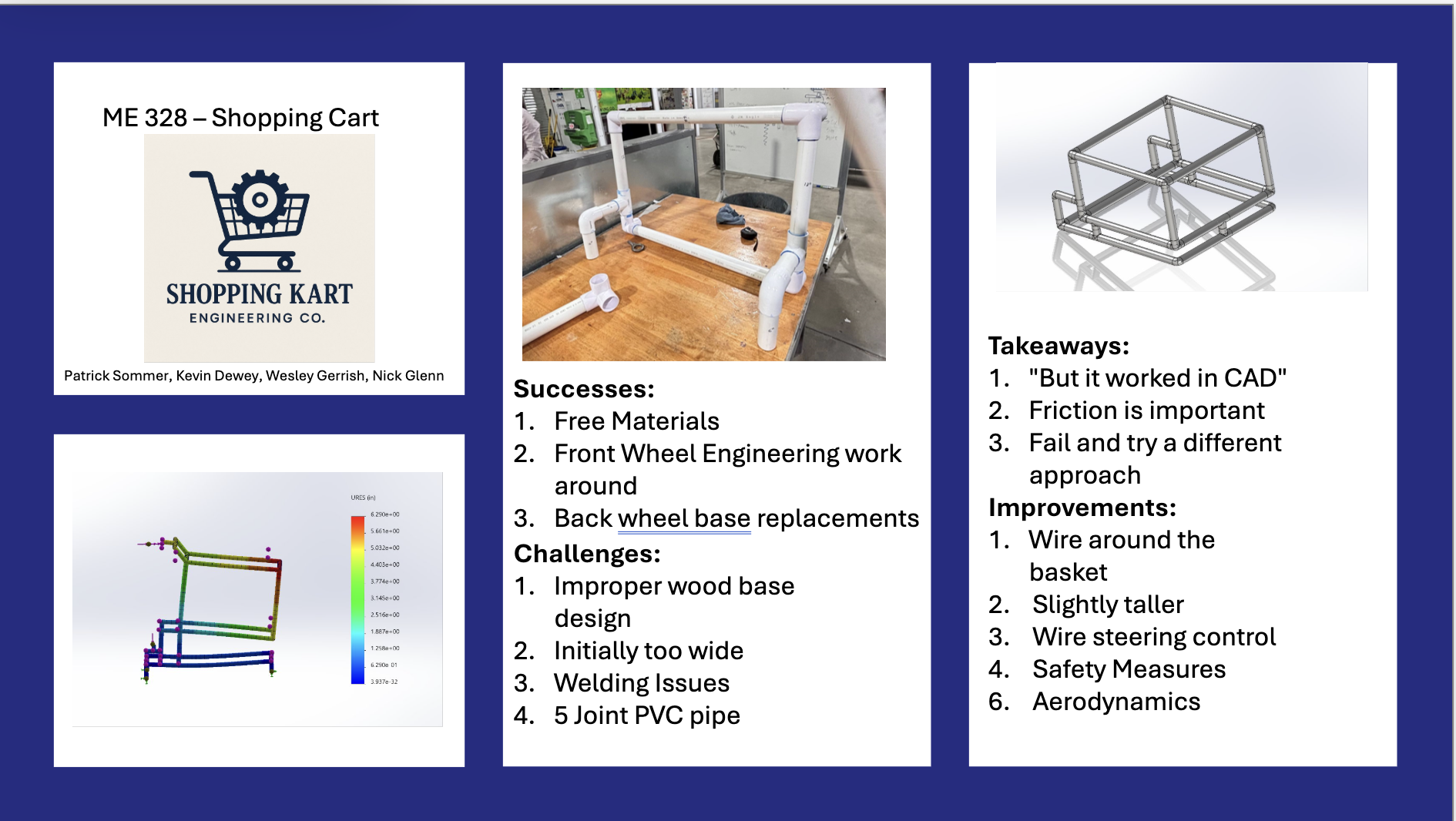

Design & Modeling: Used SolidWorks for all conceptualization and detailed CAD modeling, producing a full set of part and assembly drawings, complete with a Bill of Materials (BOM) and GD&T.

Structural Analysis: Established critical load cases, including design for strength, stiffness, and abuse cases

Physical Validation: Developed and executed a rigorous testing plan that involved component prototyping and measuring deflection at critical points on the final design

Open-Source Deliverables: The final deliverable was a comprehensive design package and a report written for an open-source design forum

This project provided hands-on experience in managing a complete mechanical system from initial concept through physical validation.