Project Overview

I am part of the payload engineering team for the 2025–2026 Northrop Grumman Collaboration Project (NGCP), a year-long aerospace program in which Cal Poly San Luis Obispo and Cal Poly Pomona jointly design, build, and demonstrate a multi-vehicle autonomous search-and-rescue mission. The system includes two UAVs, an amphibious ground vehicle, and a shared ground control station (GCS). CPP leads the GCS and ERU platform, while CPSLO leads the Med-Evac Aircraft (MEA), where my subsystem is integrated. All engineering—including CAD, analysis, prototyping, manufacturing, testing, and documentation—is performed entirely by students using industry-standard processes.

My responsibility is the MEA's payload deployment mechanism. The entire aircraft is restricted to a 10-lb maximum takeoff weight, so the mechanism must be lightweight while reliably handling a 6-lb mechanical load during operation. The current design uses a rack-and-pinion lift system, supported by gear and pulley components, with dual bay doors that open and close in sync with the platform's movement. The assembly mounts inside the fuselage and must satisfy NGCP structural, safety, and system-integration requirements.

Across the year, the team produces major engineering deliverables, including the System Requirements Review (SRR), Preliminary/Critical Design Review (PDR/CDR), subsystem design descriptions, biweekly weight-tracking documents, full mission simulations, and coordinated cross-campus interface documentation with Cal Poly Pomona's ground control and vehicle teams. The project culminates in an in-person autonomous flight and rescue demonstration at Northrop Grumman's facilities in spring 2026, where the MEA will deploy the payload mechanism during the evaluated mission scenario.

Work Completed So Far

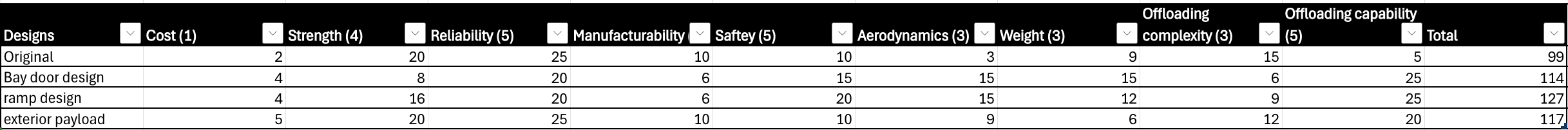

Developed multiple payload concepts and evaluated them using a full Pugh Matrix (cost, strength, reliability, manufacturability, weight, aerodynamics, offloading capability)

- Selected the rack-and-pinion + bay door mechanism as the optimal design based on scoring.

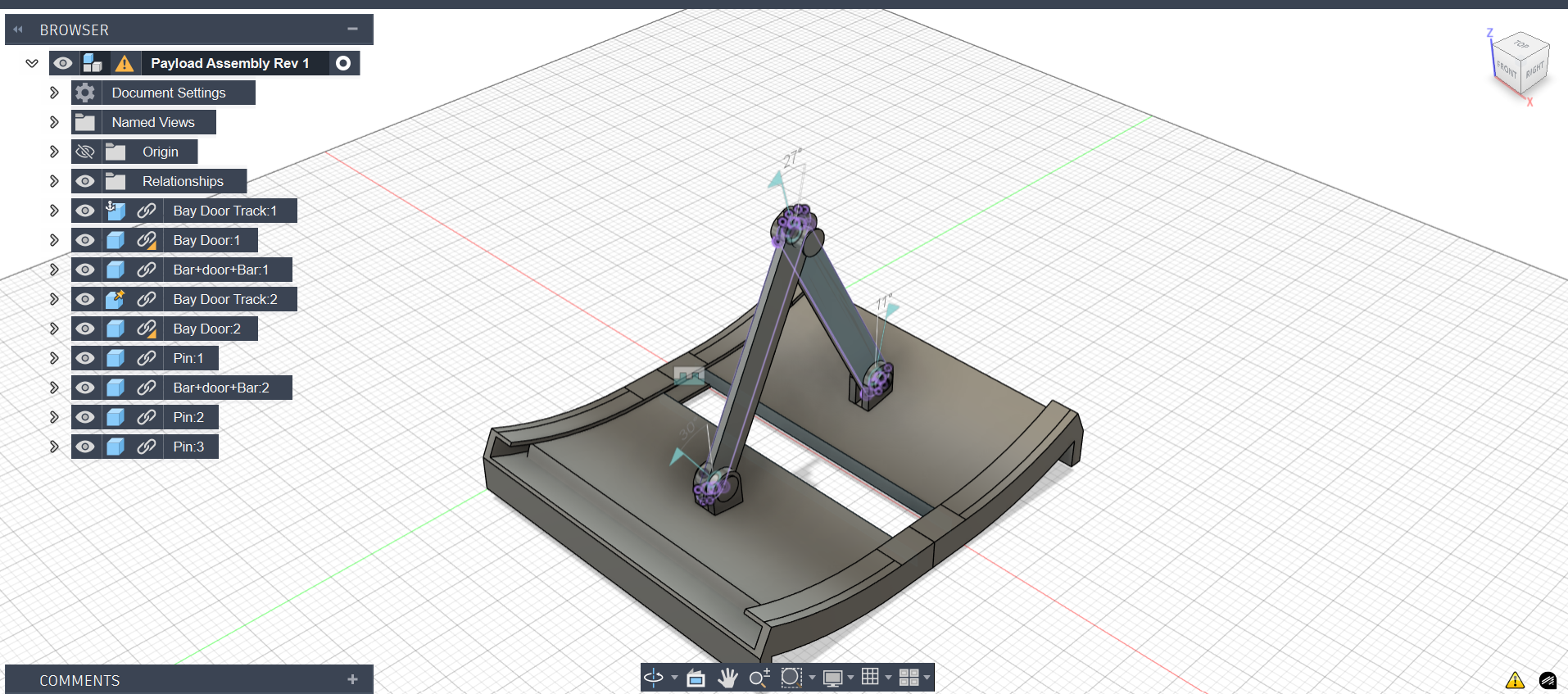

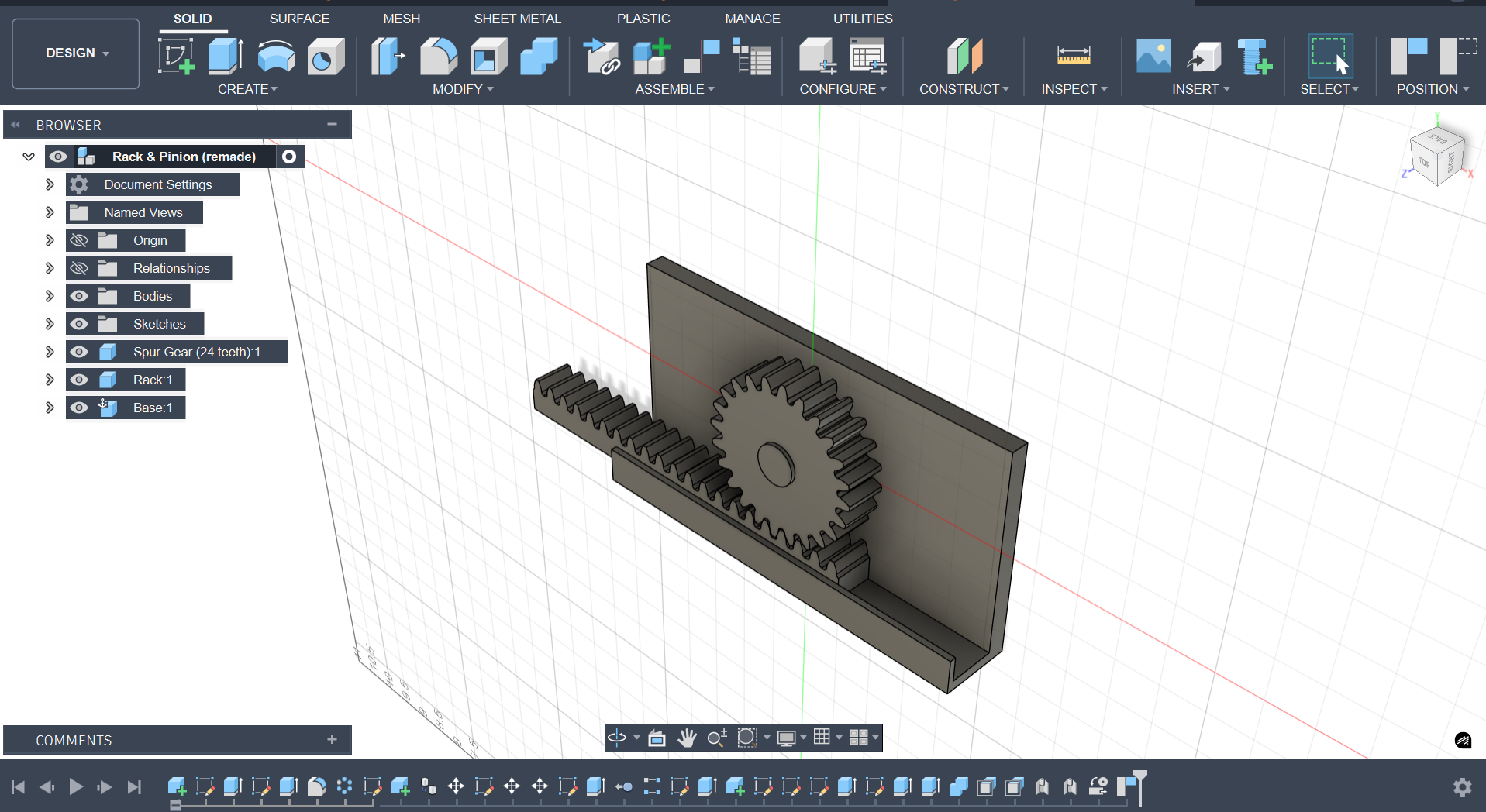

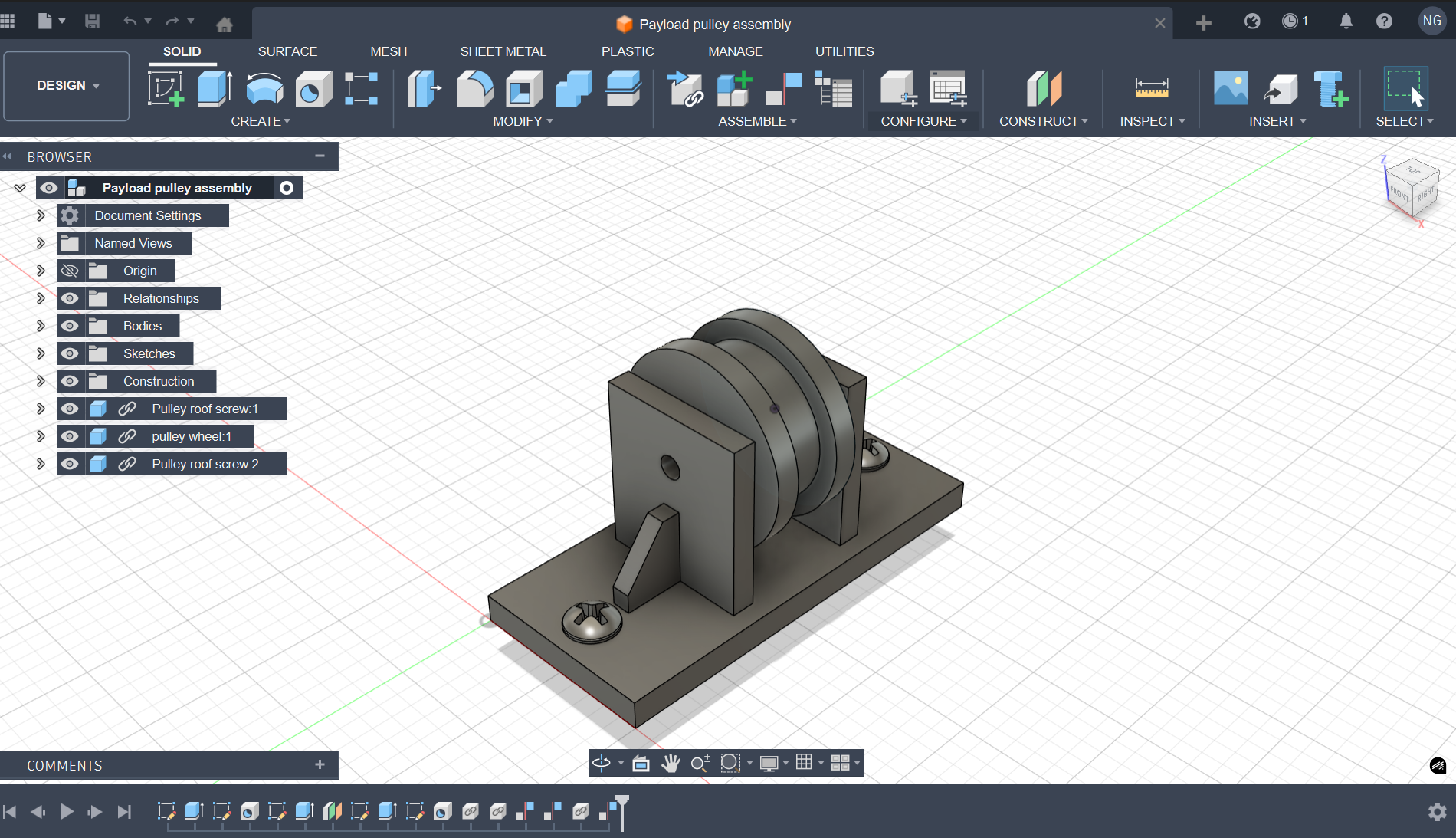

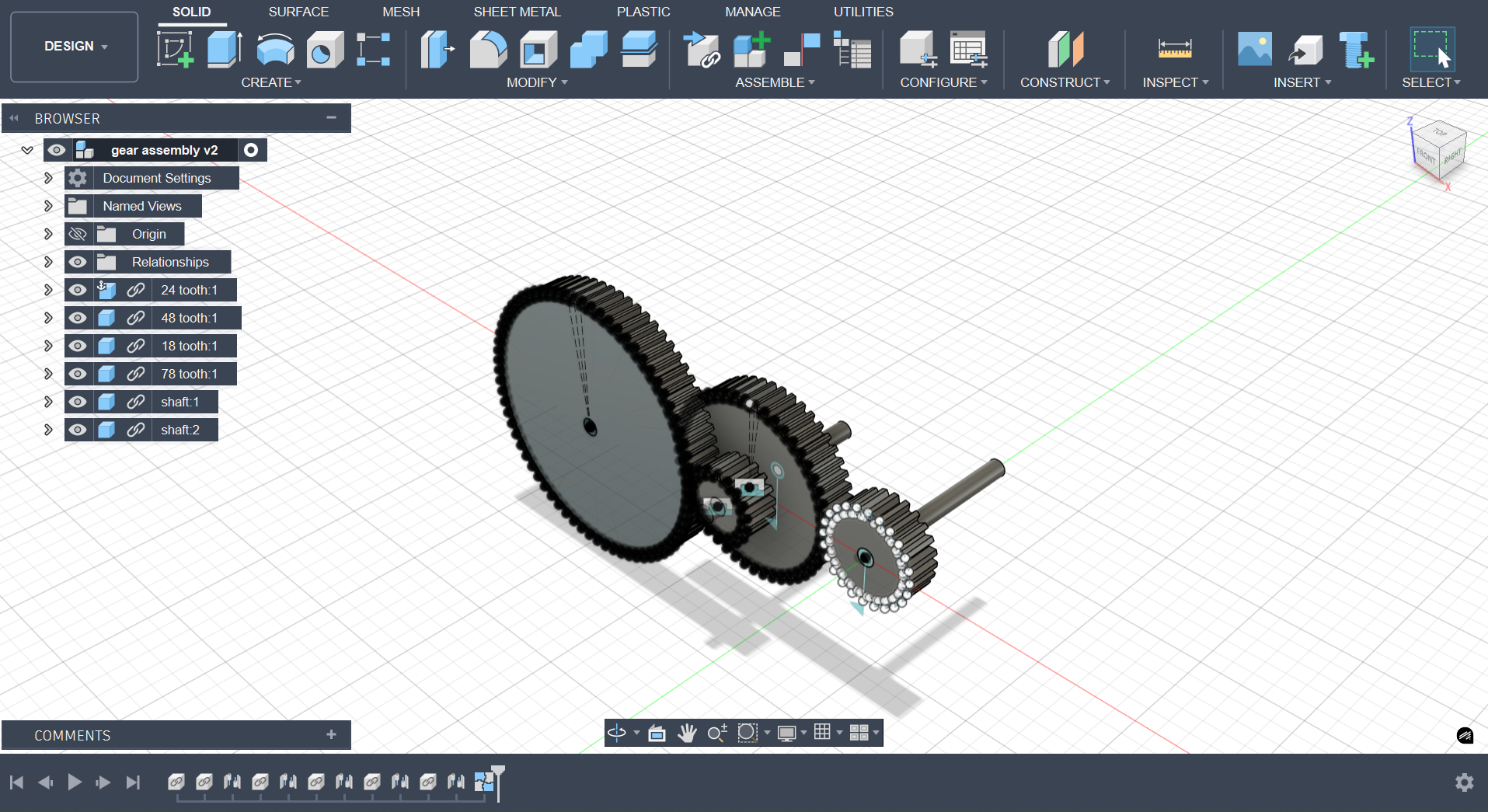

- Built detailed CAD (See Below) models of:

- Rack and Pinion Lift Assembly

- Gears and Pulleys

- Dual mechanical bay doors with hinge/linkage bars

- Integration setup for interior fuselage mounting

- Created motion simulations to validate lift travel, door synchronization, and component clearance.

- Performed early weight and structural feasibility checks to meet the 10-lb payload limit and 6-lb operating load requirement (per NGCP RFP specs ).

- Began 3D printing prototypes for dimensional refinement and early fit testing

(CAD Designs)

1. Bay door

2. Rack and Pinion Mechanism

3. Pulley

4. Gears

To Be Completed

- Finalize structural and kinematic design of the rack-and-pinion lift system, including torque calculation, gear ratios, and stress analysis under the 6-lb operating load

- Complete bay door synchronization, refining hinge geometry, linkage bars, and timing so the doors open and close smoothly throughout platform travel

- Perform full SolidWorks Motion Studies to verify clearances, contact behaviors, deployment kinematics, and potential failure modes

- Fabricate and assemble physical prototypes using 3D printing, laser-cut components, and machined hardware to validate dimensions, tolerances, and motion behavior.

- Integrate the payload assembly into the MEA fuselage, ensuring proper structural mounting, weight distribution, and compatibility with aircraft center-of-gravity requirements.

- Conduct subsystem-level testing, including lift actuation tests, durability checks, and repeated-cycle deployment trials.

- Collaborate with Cal Poly Pomona’s Ground Control Station (GCS) team to define interface control documents (ICDs) and communication needs for mission simulation.

- Prepare NGCP engineering deliverables, including:

- Subsystem Design Description for PDR/CD

- Updated biweekly Weight Breakdown Document

- Manufacturing plans and assembly drawings

- Mission simulation integration package

- Support flight readiness testing leading up to the Spring 2026 Northrop Grumman Demo Day.

- Finalize and validate the full system, ensuring the MEA can autonomously deploy the payload during the official rescue mission demonstration.