1. Introduction

This project involved the design and fabrication of a 5.712 GHz, 1.6-cell π-mode RF photoinjector developed to investigate advanced photocathode dynamics at high accelerating gradients. The original cavity geometry was invented at INFN (Italian National Institute for Nuclear Physics), later adapted at UCLA who completed the vacuum-space mechanical design, and subsequently optimized by SLAC, which refined the RF cell profiles for enhanced performance.

At Dymenso, I was responsible for the complete mechanical

realization of the photoinjector, including:

- Precision

alignment of the four copper quadrants

- Design

of custom alignment hardware

- Mechanical

design of the cooling system

- Development

of braze joints, braze sequences, and all vacuum-sealing

features

- Design

of cavity tuners for resonance correction

- Full

metrology-based validation using CMM and RCA

- Complete

assembly and brazing of the full prototype

My role covered the entire second revision and the later half of the first revision, giving me early exposure to the full product-design cycle—from design changes to fabrication readiness, integration, and final delivery.

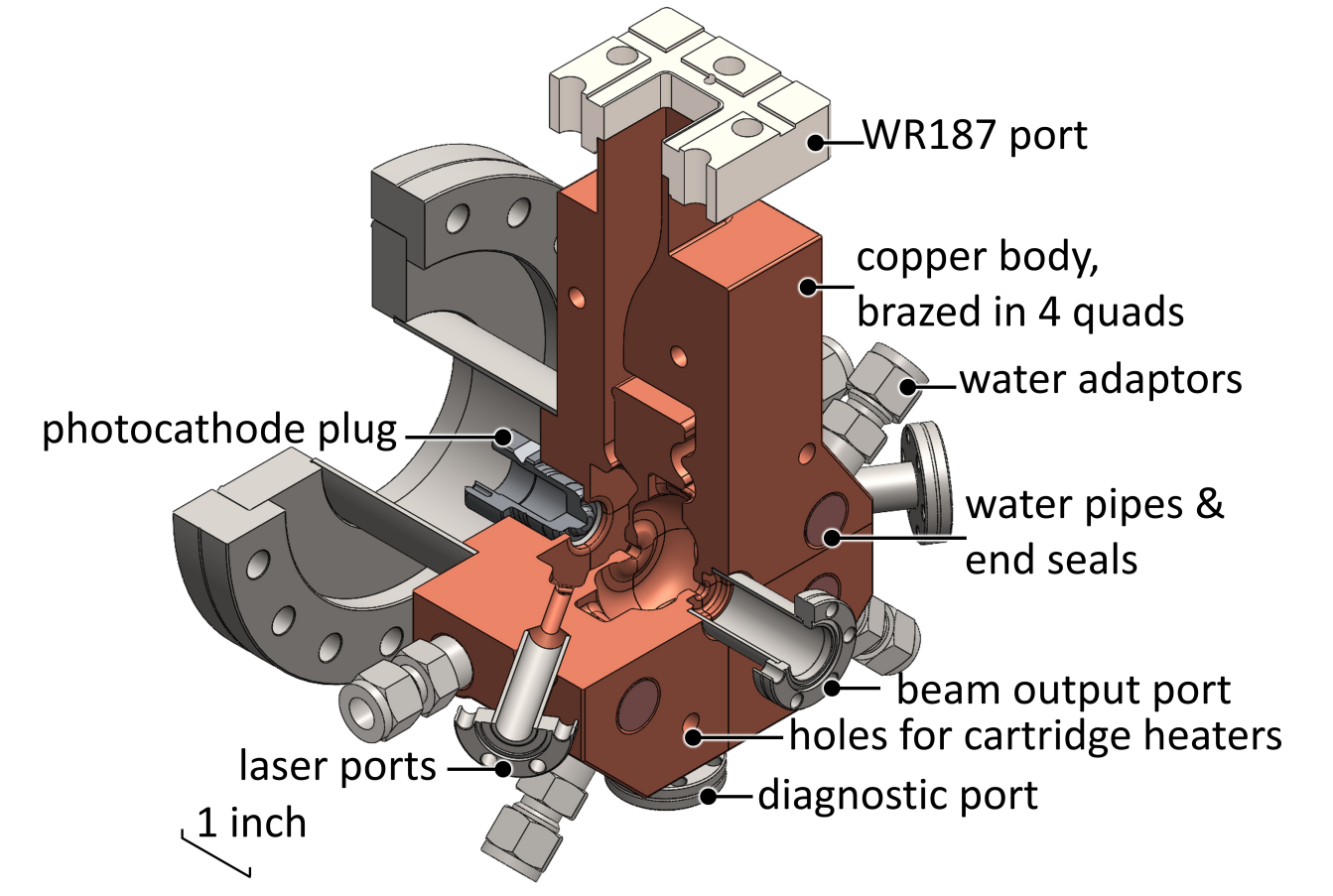

2. Design Summary

The photoinjector is fabricated as a four-quadrant OFE

copper braze assembly, with Rev-2 incorporating significant mechanical and

RF improvements to enhance accelerating-gradient efficiency and

manufacturability.

RF Design and CST Simulation Outcomes

CST High Frequency Solver simulations guided the RF shaping

and were used to verify mode behavior, surface fields, and thermal response:

- Electric

field magnitude of 240 MV/m at the cathode center in the π-mode.

- Operation

at critical coupling, with the waveguide network enforcing a 180°

RF phase delay between the half-cell and full cell.

- An arc-shaped choke at the top of the split waveguide helps shape the power flow, ensuring that both cells reach the same peak surface electric field.

- Peak

surface electric field: 316.8 MV/m located at the end of the full cell profile near the half cell.

- Peak

surface magnetic field: 478 kA/m at the coupling port, producing a pulsed

temperature rise of 48 K.

These simulation results served as the reference targets for

tuner design, feature optimization, and mechanical integration.

Major Structural and Mechanical Design Features

The following includes all major structural and Mechanical design components :

- 6-inch

Conflat flange interfaces with the photocathode and supports alignment

tooling.

- A WR187

waveguide supplies RF power to the cavity chain.

- Two mini-Conflat

laser ports are brazed to the cavity wall for photocathode

illumination.

- A 304L

stainless-steel knife-edge supports longitudinal photocathode

positioning and was designed to withstand 50 N before yielding.

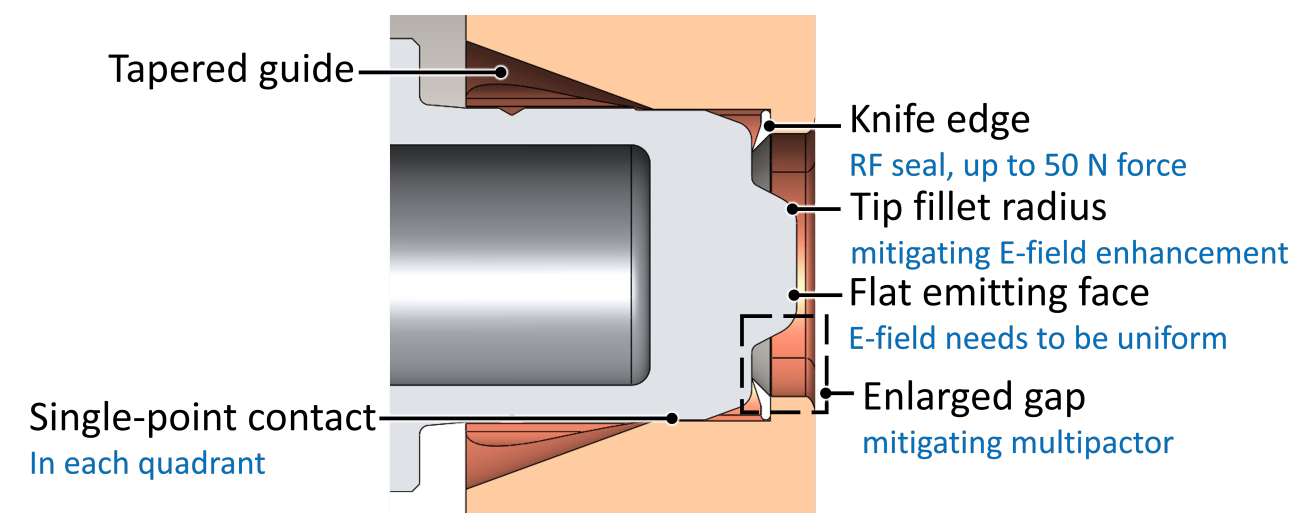

- The

photocathode plug includes:

- Field-minimizing

fillets

- A tapered

guide for centering without detuning

- A copper gap to prevent cavity-resonance distortion from cathode surfaces

- In the assembled configuration, the plug’s transverse alignment is defined by single-point contacts with each of the four copper quadrants.

- Revisions

improved the RF cell geometry and manufacturability across the

four-quadrant layout.

Assembly, Brazing, and Hardware Engineering

I led the development of all braze-ready hardware and

assembly methodologies, including:

- Iterated braze washer designs to maximize bonding surface area, promote full braze-material melting, enhance structural strength, eliminate void formation, and ensure long-term UHV-compatible sealing.

- Creation

of a complete braze hardware system composed of:

- Quadrant

braze joints

- Swagelok-based

water-cooling fittings

- Laser-input

port brazes

- Water

channel plugs

- Cathode-insertion

structural hardware

- Fixturing clamps and stability points for brazing cycles

- Conflat Flange attachments (inputs, outputs, and diagnostic ports)

- Detailed

alignment strategies ensuring quadrant coaxiality, minimal radial

deviation, and symmetric cavity formation.

- Full CMM

metrology and RCA validation of all key dimensions, alignments, and

assembly tolerances.

- Design

of cavity tuners enabling resonance adjustments.

- Development of the complete final assembly used for vacuum qualification and RF

testing.

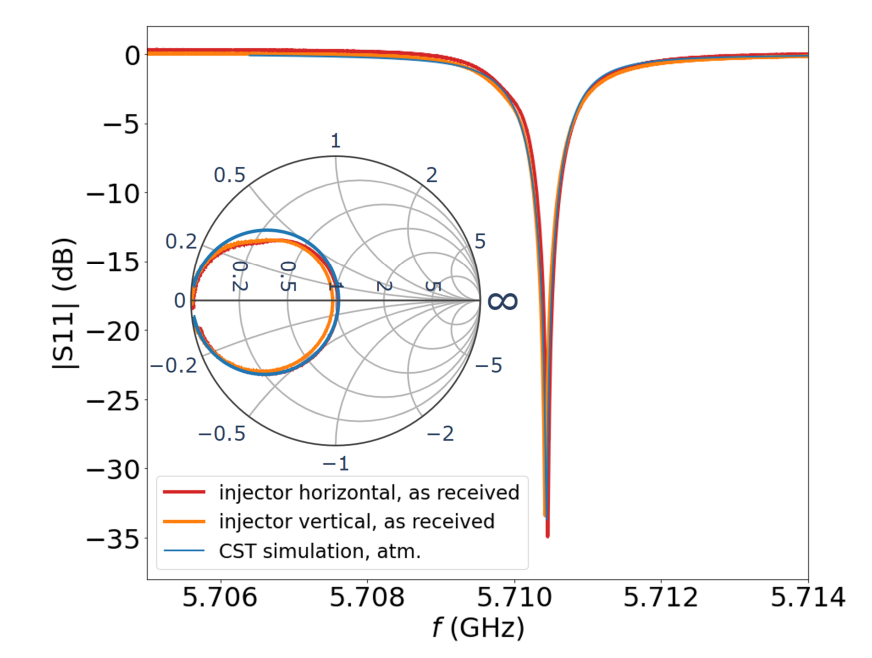

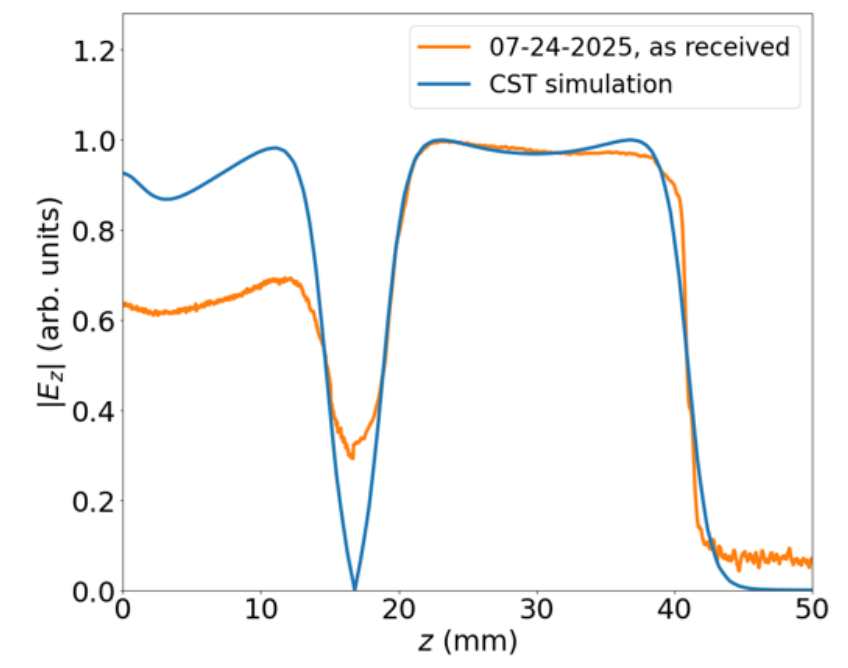

3. Low-Power RF Test Results

Low-power testing employed a bead-pull technique,

facilitated by a 0.7 mm hole drilled into the cavity to allow threading

of a nylon bead-pull line.

Key Findings

- Resonant frequencies closely matched CST simulations with minimal S11 reflection coefficents, demonstrating highly accurate machining, brazing, and material behavior.

- Bead-pull

measurements revealed the cathode-region electric field amplitude was 32%

lower than simulation, consistent with expected losses and correctable

through tuner adjustments.

- The

measured RF phase advance between the cavity cells was 183°,

nearly identical to the 180° design target, confirming proper

coupling and quadrature symmetry.

These results validated the mechanical build quality and

confirmed that the Rev-2 cavity behaved as expected in the π-mode.

4. Conclusions

The successful design, fabrication, brazing, and low-power

testing of the 5.712 GHz RF photoinjector demonstrates the effectiveness of the

quadrant-based manufacturing process, tuner architecture, and alignment

methodologies. Despite moderate electric-field deviations near the

photocathode, the cavity met critical RF design requirements including

resonance, phase behavior, surface-field distribution, and coupling symmetry.

This project strengthened my experience in:

- Precision

RF-structure design

- Vacuum

and braze engineering

- Quadrant-based

fabrication

- Tuner

development

- CMM-based

tolerance validation

- RF–mechanical

integration from concept to prototype