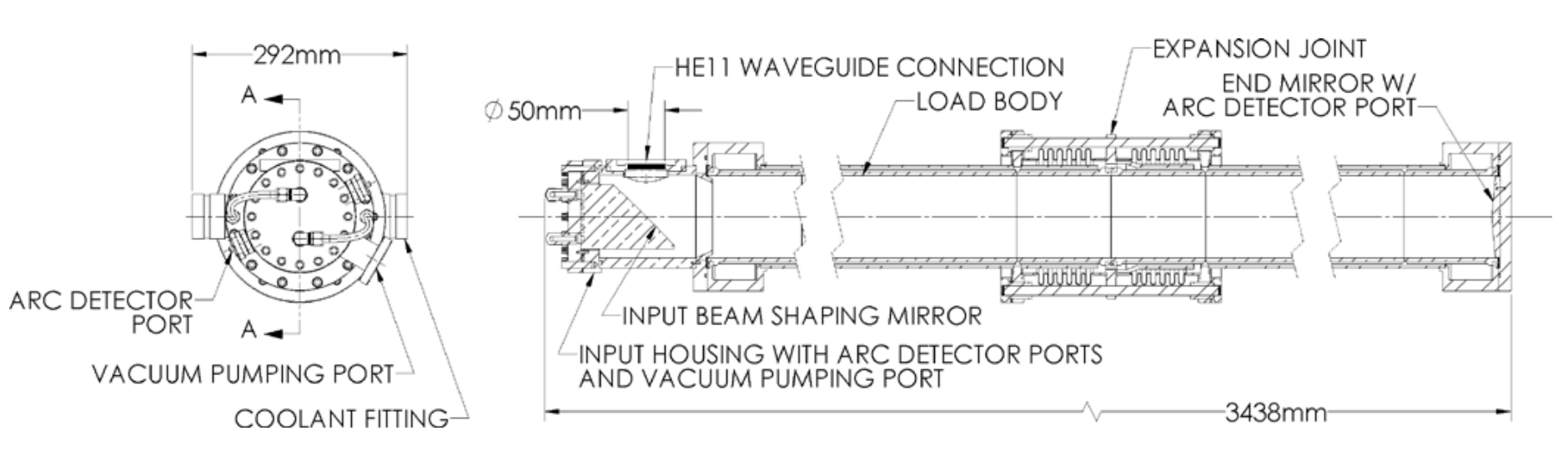

The ITER RF Dummy Load is a high-power dissipation system

designed to safely absorb nearly 1 megawatt of millimeter-wave radiation

generated by the fusion reactor’s gyrotron sources; image above shows full assembly in isometric view. Operating at 170 GHz,

the load receives electromagnetic power through a specialized waveguide and

redirects it off a precision-machined 45° wave profile input mirror. This mirror shapes

the incoming wave profile and routes it into the long absorption tube. Inside

the tube, a high-reflectivity end mirror bounces residual RF energy back

and forth along the length of the structure, forcing multiple passes through an

inner TiO₂-based coating. Each pass converts more RF energy into heat,

allowing the coating to safely dissipate massive power densities without

damage. Ultimately, the system must maintain mechanical stability, vacuum

integrity, and cooling performance throughout long-pulse, high-power operation.

To handle extreme thermal gradients, the load incorporates:

- a mid-body

expansion joint to accommodate structural growth

- active

water-cooling channels running the length of the assembly

- full-penetration

vacuum welds on every joint

- complete

vacuum compatibility and leak-tightness requirements for ITER

hardware

Below demonstrates a more detailed visual of the RF Load Internals disscussed.

I contributed to multiple stages of the prototype

fabrication, inspection, and test-readiness phases:

Metrology & Manufacturing Validation

- Performed

CMM inspections on critical components to verify machined geometry,

flange alignments, and weld-prep surfaces.

- Conducted

root-cause analysis (RCA) to identify deformation arising from

welding, machining sequence, and mechanical distortion during prototype

fabrication.

- Helped

verify that all components met ITER’s stringent tolerances and vacuum

hardware requirements.

Assembly & Integration

- Supported

mechanical assembly of the load structure, including alignment of

the 45° input mirror, end mirror, expansion joint, spot-weld prep, cooling-path routing, and

installation of vacuum-rated seals.

- Assisted

with fixture handling, lifting operations, fabrication and install of RF Load stand with external water and vacuum peripheral attachments, and final packaging for

international shipment.

High-Power Testing Support

- Prepared

the load for long-pulse RF testing at the Swiss Plasma Center (SPC) in

Lausanne (Switzerland).

- Test

conditions reached 800 kW, 10-second pulses, during which:

- thermal

stabilization occurred within the pulse duration

- vacuum

pressure remained stable

- RF

measurements showed low reflection, confirming proper absorption

behavior

These successful tests validated the integrity of the absorber design, thermal performance, vacuum weld quality, and internal TiO₂ coating absorption characteristics.

RF Load being at Swiss Plasma Center (SPC) during high power long pulse testing.