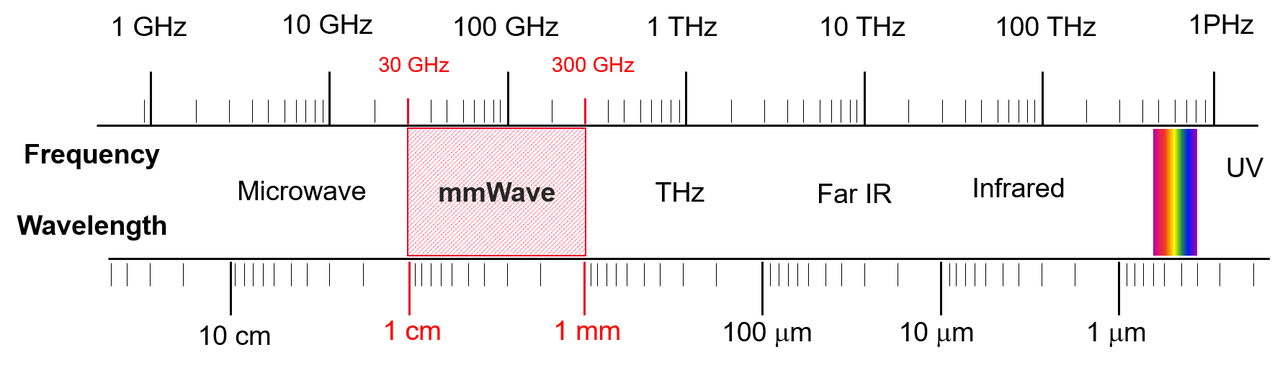

1. Introduction

Recent advancements have made sub-micron machining of individual mm-wave components achievable, but assembling multiple parts to those same tolerances remains a major manufacturing challenge. Traditional alignment methods—such as pins or in-process machining—typically achieve only ~10 µm accuracy and require labor-intensive manual fitting by skilled technicians.

To overcome these limitations, I evaluated and implemented high-precision alignment strategies including kinematic couplings, quasi-kinematic interfaces, and elastic averaging into a mm-wave W-band Traveling Wave Tube (TWT) amplifier to demonstrate fabrication potentials. These methods enable repeatable sub-micron alignment, reduce dependency on manual alignment, and significantly improve throughput potential. These techniques help minimize variations in output power and efficiency, ultimately enabling consistent, higher-performance mm-wave sources at lower production cost [1].

2. Alignment Techniques

To achieve sub-micron assembly accuracy in mm-wave devices, I evaluated three advanced alignment strategies—each offering unique advantages over traditional pin-based or in-process machining methods [1].

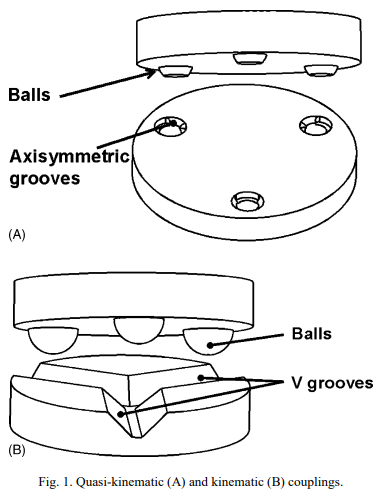

Kinematic Couplings (KC)

Kinematic couplings use three ball-in-groove contacts to constrain all six degrees of freedom deterministically. Because each contact point is defined, KCs deliver highly repeatable, predictable alignment at low cost and with minimal manufacturing complexity.

Quasi-Kinematic Couplings (QKC)

QKCs replace point contacts with arc contacts, creating larger contact areas that reduce stress and material requirements while enabling sub-micron accuracy. Their geometry also allows the interface to double as a sealing surface—valuable for vacuum and mm-wave assemblies [2].

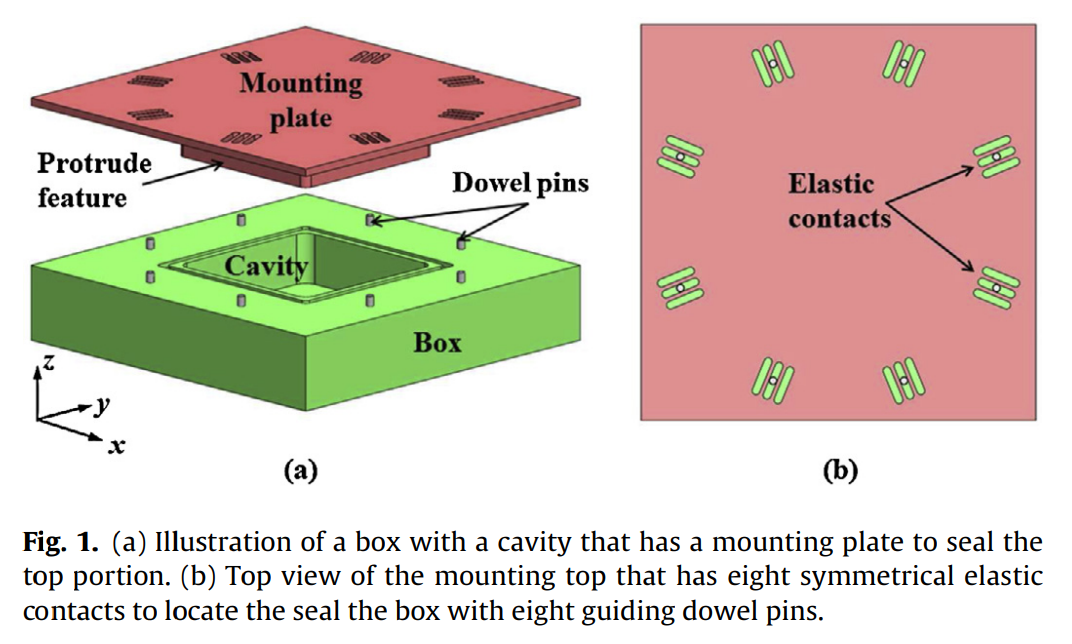

Elastic Averaging

Elastic averaging distributes many small precision engineered pins that interface compliant contact features across a broad area. When preloaded, these features deform slightly, averaging out individual geometric errors. While less deterministic than KCs, elastic averaging provides high stiffness, load robustness, and excellent repeatability—improving as the number of contact points increases [3].

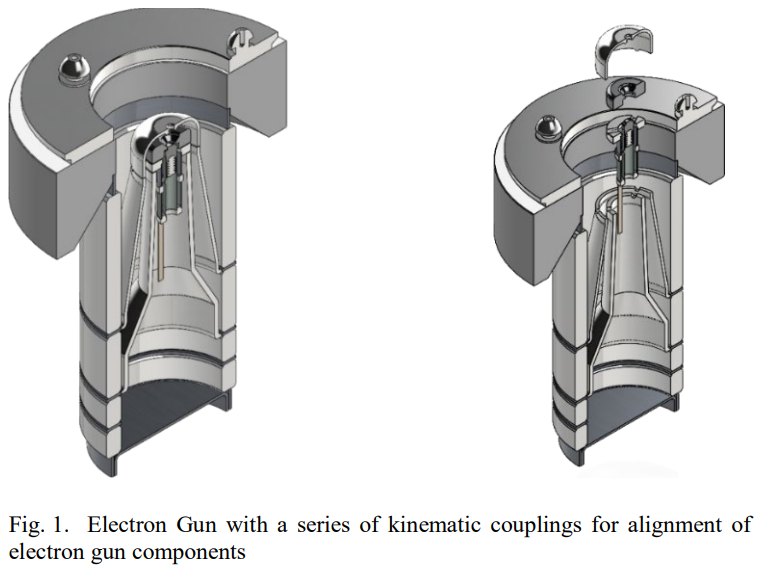

3. Electron Gun Design

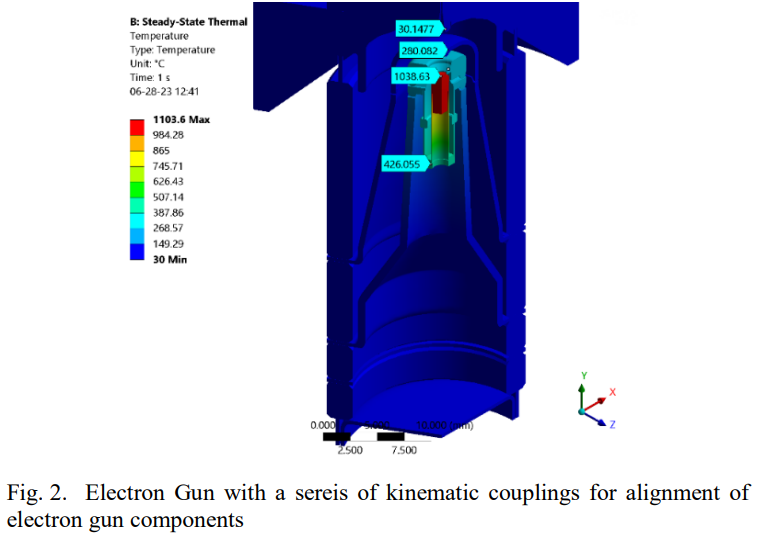

In the electron gun design, kinematic couplings were used to precisely align the cathode, focus electrode, and mod-anode. By placing the cathode and mod-anode couplings in a coplanar arrangement, assembly errors were minimized and sub-micron repeatability was maintained across stacked interfaces with other mm-wave beamline assemblies. Shown bellow is the full stack of kinematic coublings aligning the cathode, focus electrode, and mod-anode.

To evaluate thermal behavior, ANSYS thermomechanical simulations was performed to model heat flow and thermal expansion. The cathode operates near 1030 °C, and the kinematic coupling’s point-contact geometry provides strong thermal isolation between components shown below. This reduces heater power requirements, limits thermal distortion, and ensures stable, repeatable electron emission performance under high-temperature operation [1].

4. Circuit Alignment

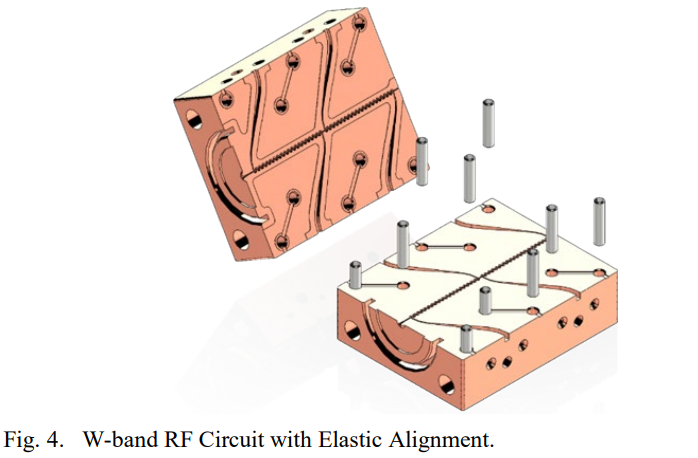

The RF circuit (Figure 4) was constructed from two precision-machined copper halves featuring a distributed set of alignment features around the periphery. I designed the alignment geometry, SolidWorks assemblies, and brazed vacuum interfaces, incorporating C-shaped alignment pins to create an elastic-averaging interface. When preloaded, these pins allowed small geometric deviations to be averaged out across multiple contact points, improving assembly repeatability, stiffness, and RF circuit concentricity [1]. The elastic averaging used in the W-band RF amplifier circuit is shown below.

I validated the manufacturing and assembly accuracy through sub-micron CMM inspection, confirming reliable alignment across multiple builds. This alignment architecture demonstrated a scalable, manufacturable approach for mm-wave device fabrication—offering improved mechanical stability, reduced assembly labor, and robust vacuum compatibility for high-frequency operation.

5. Conclusions

This work demonstrates a scalable, high-precision alignment framework for W-band mm-wave devices by integrating kinematic couplings, quasi-kinematic couplings, and elastic averaging into both the electron gun and RF circuit assemblies. These methods achieved repeatable sub-micron alignment, reduced assembly complexity, and improved thermal and mechanical stability across the beamline.

Through SolidWorks design, thermomechanical simulation, and sub-micron CMM verification, I showed that deterministic and elastic-averaging interfaces can significantly enhance manufacturability while maintaining performance-critical tolerances. The resulting alignment architecture minimizes power and efficiency variations, enables reliable high-temperature operation, and reduces reliance on skilled manual assembly.

Overall, this work highlights a practical path toward more consistent, cost-effective, and production-ready mm-wave TWT amplifier fabrication, supporting future scaling of precision RF device manufacturing.

Refrences

[1] P. Borchard et al., "Fabrication of W-Band Traveling Wave Tube Amplifier Beamstick Using Precision Alignment Techniques," 2024 Joint International Vacuum Electronics Conference and International Vacuum Electron Sources Conference (IVEC + IVESC), Monterey, CA, USA, 2024, pp. 01-02, doi: 10.1109/IVECIVESC60838.2024.10694878. keywords: {Couplings;Fabrication;Electron beams;Traveling wave tubes;Kinematics;Electron guns;Vacuum electronics;Electron sources;precision alignment;W-band;electron gun;TWT;elastic averaging;kinematic coupling;microfabrication},

[2] Culpepper, Martin L. “Design of Quasi-Kinematic Couplings.” Precision Engineering, vol. 28, no. 3, July 2004, pp. 338–357, https://doi.org/10.1016/j.precisioneng.2002.12.001.

[3] Teo, Tat Joo, and Alexander H. Slocum. “Principle of Elastic Averaging for Rapid Precision Design.” Precision Engineering, vol. 49, July 2017, pp. 146–159, web.mit.edu/2.70/Reading%20Materials/Elastic%20averaging%20paper%202018.03.19.pdf, https://doi.org/10.1016/j.precisioneng.2017.02.003. Accessed 3 Dec. 2025.