Problem Statement

The accumulator cart's predecessor was an old and worn-out plastic U-line cart, not unsimilar to what you would see at your local bakery. It was incredibly unforgiving in the sense that it lacked modern safety features and maneuverability, specifically in the z-direction, requiring four people to remove and install the accumulator each time. Additionally, due to the cart's sheer size and location, it was often used as a storage space for a wide range of tools and parts, which compromised its utility regarding the battery.

This was not feasible, especially at competitions, where the battery was being removed constantly for slight modifications or to access other systems. This, coupled with the age and deterioration of the cart, played key roles in opting for an upgrade.

With the new cart, we wanted to:

- Reduce the people necessary for removal/installation

- Continue to allow the cart to be able to be used as a workspace

- Have the cart be a more rugged material to last longer

- Decrease the total surface area so it cannot become cluttered

- Create a display showcasing the charging status of the pack

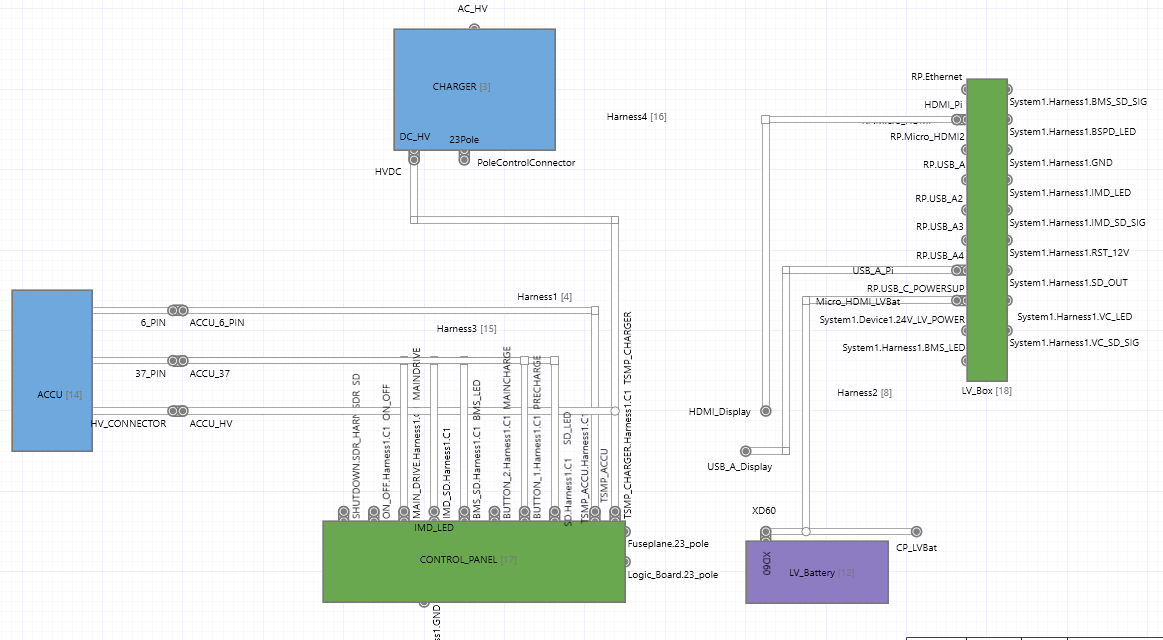

We accomplished this by first finding a steel cart that came equipped with manual lift capabilities. We then created a CAD model based on the lift table's dimensions to design a custom secondary shelf made from aluminum, which would store the battery while keeping the charger and other electrical components below. When the cart arrived, we finalized the design and started manufacturing. This involved repurposing a backplane from a previous car, adding an additional Raspberry Pi to monitor and display live charging data, drilling holes for wiring and switches, and having aluminum water jetted and bent by SAT. After all this, we had developed an accumulator cart that met all of our goals and came in under budget.

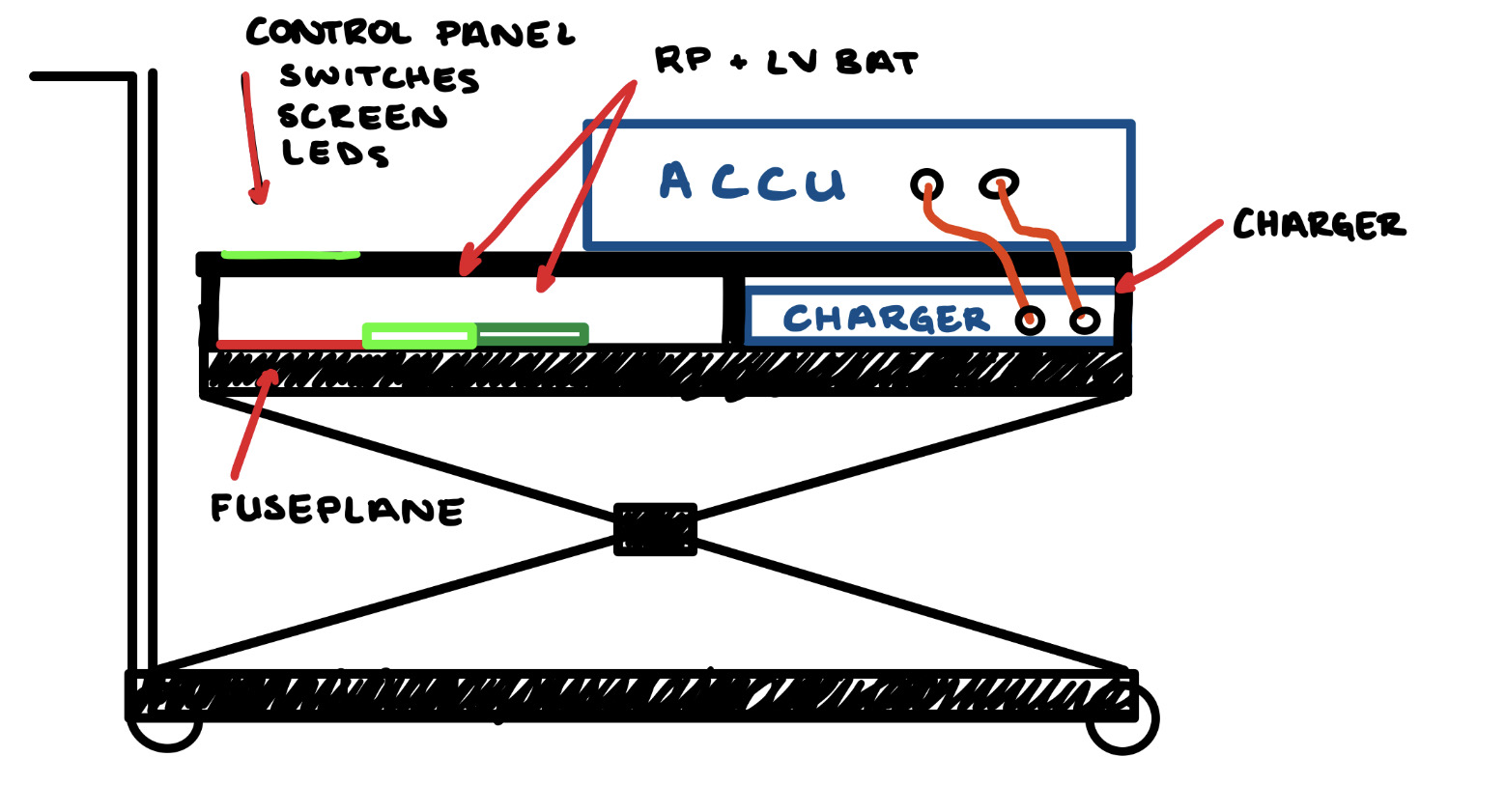

Initial Design Sketch

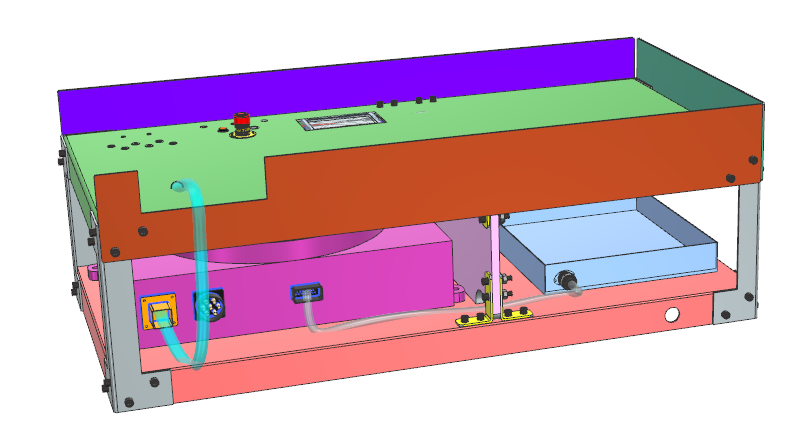

Finalized CAD/Design

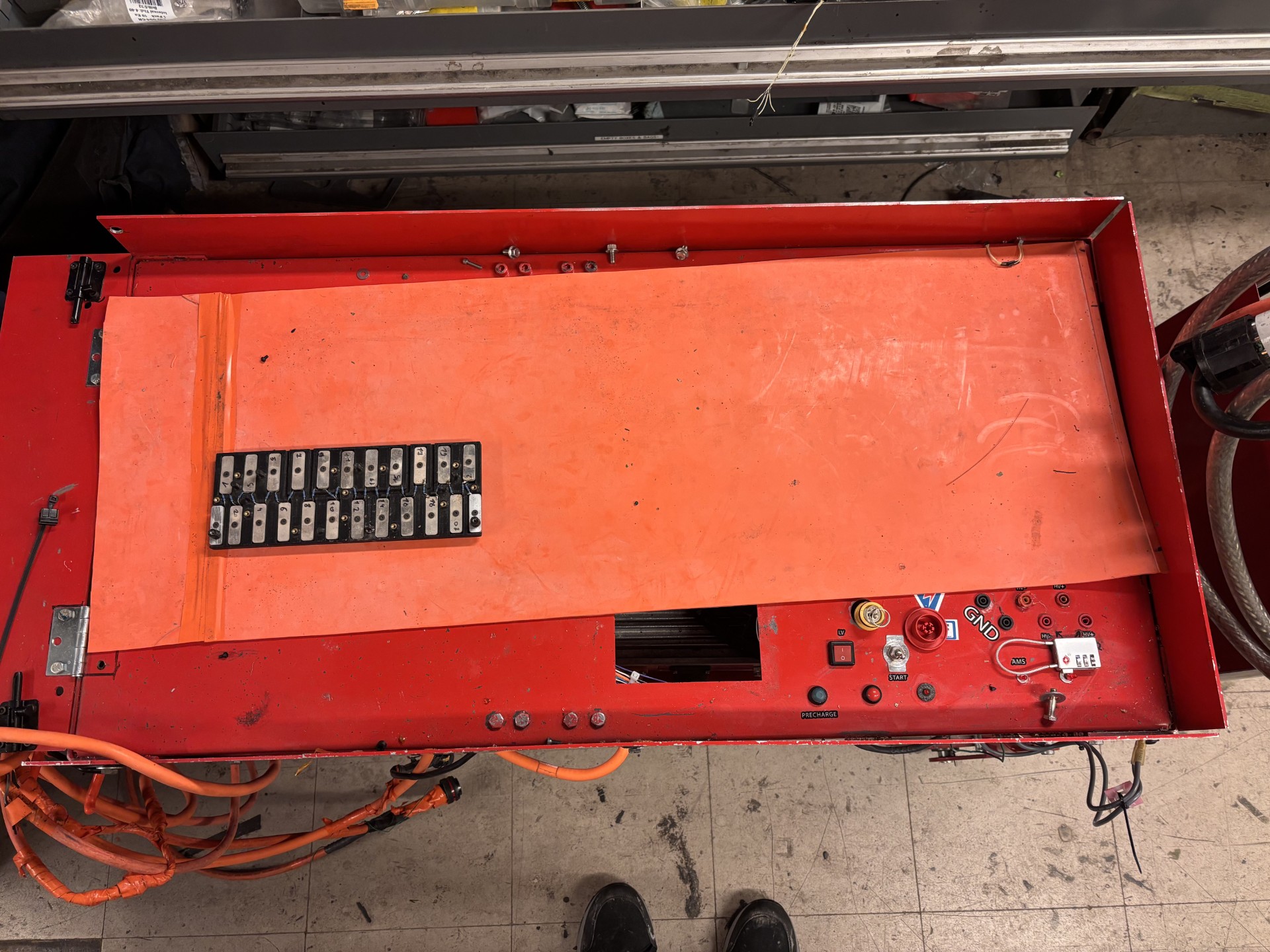

Cart Pre-Modifications

.jpg)

Implemented Design

(Raspberry Pi screen removed to prevent damage during manufacturing season)

BOM (Bill of Materials)

Budget ($2000)

| Item | Price | Quantity |

| Raspberry Pi 4B 1GB | $48.95 | 1 |

| 5" Raspberry Pi Screen | $63.99 | 1 |

| Charger | Previously owned | 1 |

| Hydraulic Lift Cart | $1,244.00 | 1 |

| Aluminum for the shelf | Sponsored by SAT | -- |

| LV Battery (24V) | Previous years from the car | 1 |

| Misc. (Switches, Wires, etc) | $100.00 | -- |

| Total (tax in) | $1,675.48 |

-- |