Gumball Machine Design Project

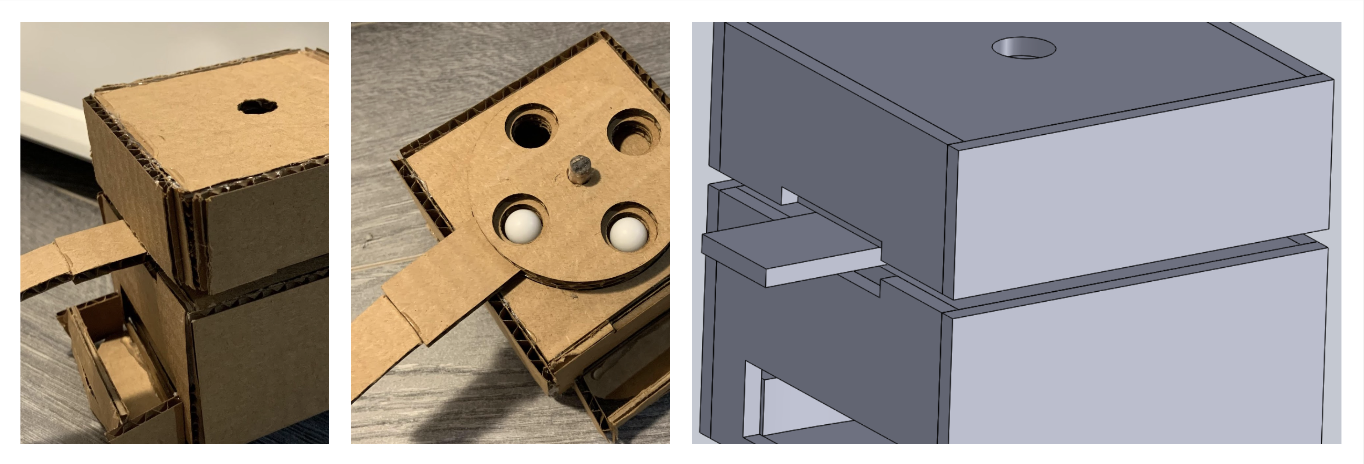

This project involved designing and constructing a custom gumball machine that was both functional and efficient while being built entirely from limited materials, including cardboard, a pencil (as a dowel), glue, tape, and basic hand tools. SolidWorks was used to develop the CAD model, ensuring precise planning and accurate fabrication. The design process emphasized creativity, problem-solving, and engineering principles, with particular focus on robustness, functionality, and user experience.

Design Development

Multiple design concepts were considered before selecting a rotating disc dispensing system. Earlier ideas included a gear-driven traditional machine, a push-pull bar mechanism, and a toilet paper roll style design, each with unique strengths and weaknesses. The rotating disc was ultimately chosen for its efficiency, simplicity, and reliability. This mechanism allowed up to four gumballs to be dispensed per full 360° rotation, meeting both functionality and efficiency goals.

Engineering Features

The final design incorporated four main sections:

-

Loading Area: Guided gumballs into the rotating disc, with angled cuts and walls to prevent spillage.

-

Rotating Disc: Spun manually via an extended handle, advancing one gumball every 90°.

-

Ramp System: Slowed gumballs and directed them into the holding section.

-

Holding Area: Contained gumballs with walls on three sides, ensuring they did not roll away.

Additional engineering refinements included extending the handle for smoother operation, adding an inclined slab to prevent gumballs from jamming in the loading area, and reinforcing structural stability with extra glue and framing. Each prototype iteration addressed specific performance issues and improved user experience.

Iteration & Prototyping

-

Prototype 1: Extended the handle for easier turning and reduced friction between components.

-

Prototype 2: Added angled cuts to the frame for smoother loading and improved usability.

-

Prototype 3: Introduced inclined supports at the back to ensure gumballs rolled consistently into the disc.

-

Prototype 4: Integrated a dedicated holding area with reinforced walls to prevent gumballs from escaping.

Outcome

The final gumball machine was robust, efficient, and exceeded design expectations. It reliably dispensed gumballs without jamming, stood up to repeated use without structural failure, and provided an engaging user experience. The machine required no maintenance, achieved consistent performance, and demonstrated a balance of creativity and engineering functionality.