DETAILS

Designed the full multi-feature fountain system layout, including laminar shooters, vertical jets, fan jets, the rotating centerpiece, and recirculating piping architecture.

Built the hydraulic model using fundamental fluid-mechanics principles: hydrostatics, conservation of mass, momentum analysis, pipe-flow relations, and viscous shear behavior.

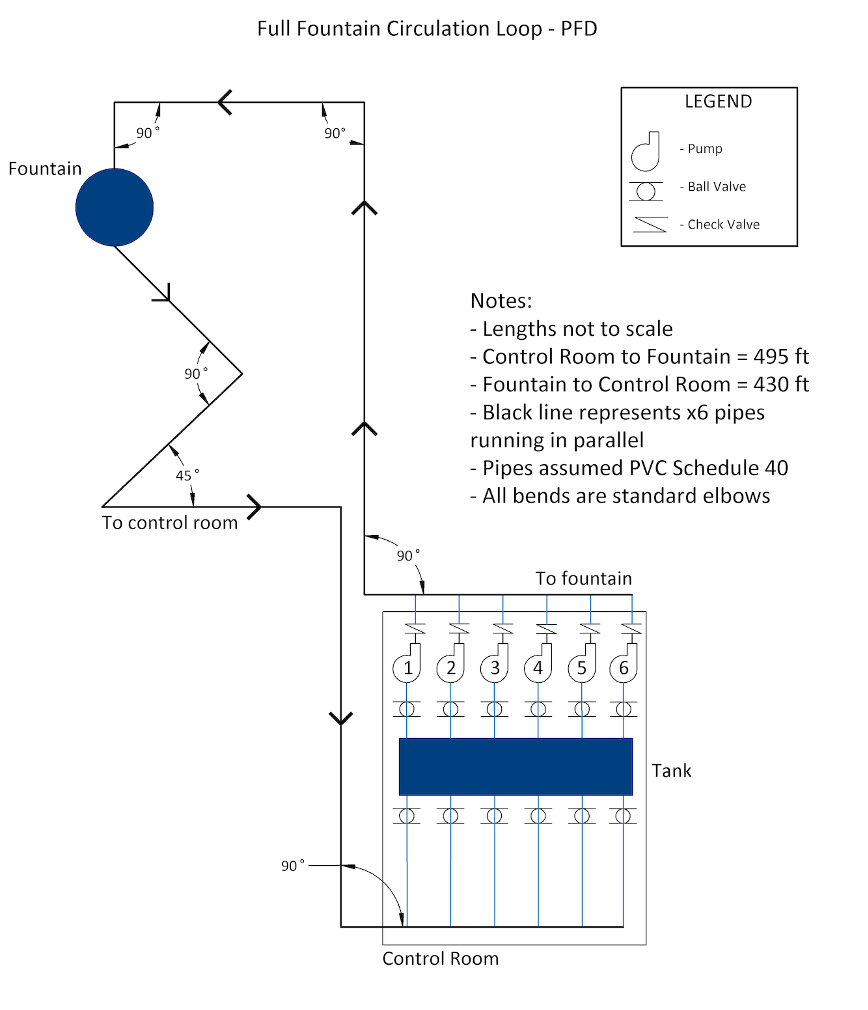

Created schematics on SolidWorks for the fountain geometry, piping network, manifolds, and routing paths, integrating real site elevation and distance data.

Modeled internal pipe-flow behavior to evaluate head loss, flow splitting, pump performance, and velocity requirements for each water feature.

Analyzed laminar shooter performance using fully developed flow derivations, verifying shear stress, velocity distributions, and straightener requirements.

Developed a scale-model similitude framework using Buckingham Pi (Re, Eu, Fr, We) to predict prototype jet behavior from a 1:4 experimental model.

Conducted free-surface flow analysis for the rotating centerpiece to confirm shear stress, flow uniformity, and long-term surface durability under gravity-driven sheet flow.

Integrated hydraulic, structural, and manufacturability constraints to deliver a complete engineering justification for system feasibility.