For DVT testing of the TempPatrol sensor, we needed to ensure that our sensor could seal at extreme pressure and vacuum conditions which exposed to 120C - (-40C) temperatures. This is consistent with the operating conditions that transformers are exposed to in operation, and during the manufacturing process.

I individually designed this jig and selected all of the components. I sent the jig’s drawings to a machine shop to be machined after approval from a senior engineer. Then, I assembled the jig and performed tests to ensure it's sealing ability.

The jig ended up sealing with a leak rate of less than 0.01psi/min which is miniscule compared to our allowable leak rate which is upwards of 0.5psi/min for all tests. It is capable of very accurately measuring our products sealing ability through extreme conditions.

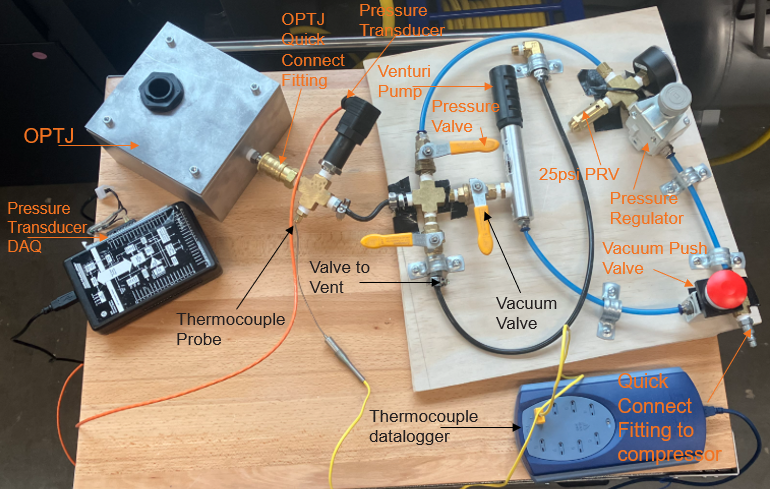

Jig Setup:

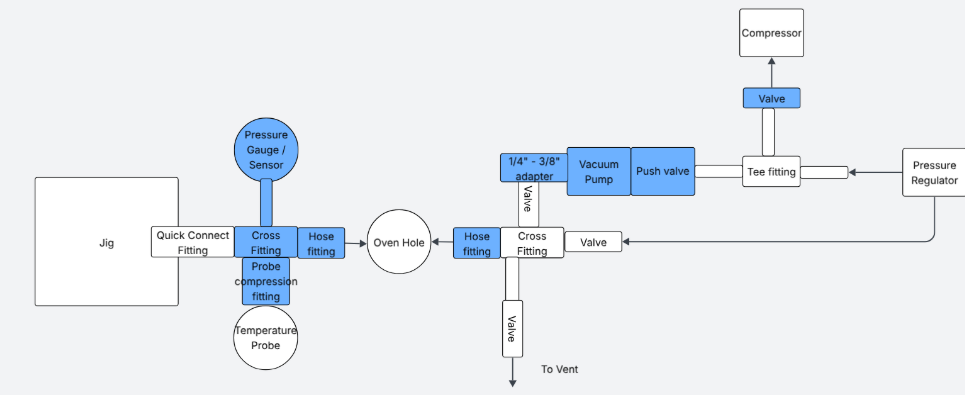

Jig Diagram: