Problem Statement

The existing drivetrain axle shafts were costly to manufacture, and posed a risk of transmitting overloads to higher-value components such as the gearbox during extreme shock loading. The project goal was to redesign the axle shafts to reduce cost and mass while ensuring predictable, sacrificial failure behavior under overload conditions.

Design Objectives

- Improve manufacturability and reduce material and processing cost

- Establish axle shafts as a mechanical fuse to protect the gearbox

- Maintain reliability and performance under Baja SAE off-road conditions

Technical Approach & Design Decisions

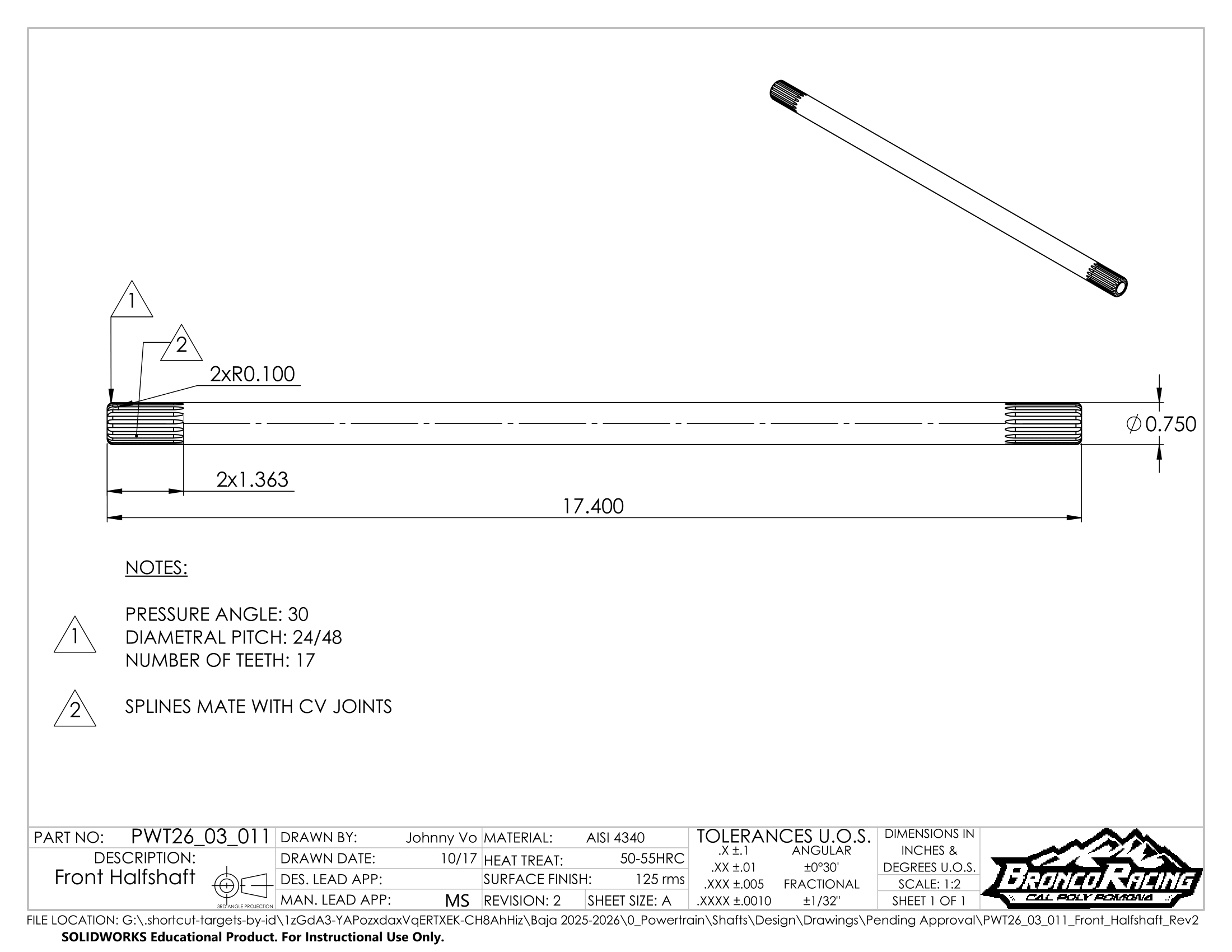

Manufacturability and cost effectiveness were improved by transitioning the axle material from 300M steel to 4340 steel. While maintaining comparable strength for the application, 4340 offered lower material and processing costs. Additionally, 4340 was better aligned with the manufacturing capabilities of our sponsor, Associated Gear, as prior experience with 300M had resulted in excessive tool wear and tooling failures during machining. This material change improved production reliability while preserving drivetrain performance requirements.

To reduce rotating mass and inertia, a gun-drilled hollow shaft design was implemented. This approach lowered mass without significantly impacting torsional stiffness. This allowed for the axle shafts to be intentionally designed with a lower factor of safety than the gearbox. By doing so, we also established the axle shafts as sacrificial components. Under overload or shock loading, failure would occur in the axle shafts rather than the gearbox, minimizing repair time and reducing the risk of catastrophic drivetrain damage during competition.

Analysis & Validation

Design decisions were supported through first-principles stress calculations, finite element analysis (FEA), and DFM/FMEA evaluations. Particular attention was given to spline geometry, stress concentrations, and likely failure modes to ensure controlled and predictable behavior

Manufacturing & Implementation

Final axle designs were manufactured through industry sponsors Associated Gear and Gun Drill Specialties.