Problem Statement

I frequently used the Bruker Hysitron Ti Premier 980 testing platform to perform micro-scratch tests on cylindrical samples. The micro-scratch test reads both the force being applied onto the sample, and the x, y, z directions. The testing platform required samples to be super glued onto a metallic puck that was then screwed into the stage, due to factors like human error and wear on the screw it was close to impossible to get a perfectly straight sample. A perfectly straight sample is important because the Bruker typically scratches along the x-axis unless customized, and with no real way to measure the angle of the wire relative to the system's x-axis; the best bet was to get a sample as straight as possible to a reference line created by the Bruker. To solve this I created an applicator fixture that rolled samples onto the puck at low enough velocity that there would be no bounce upon impact and samples would land as straight as possible.

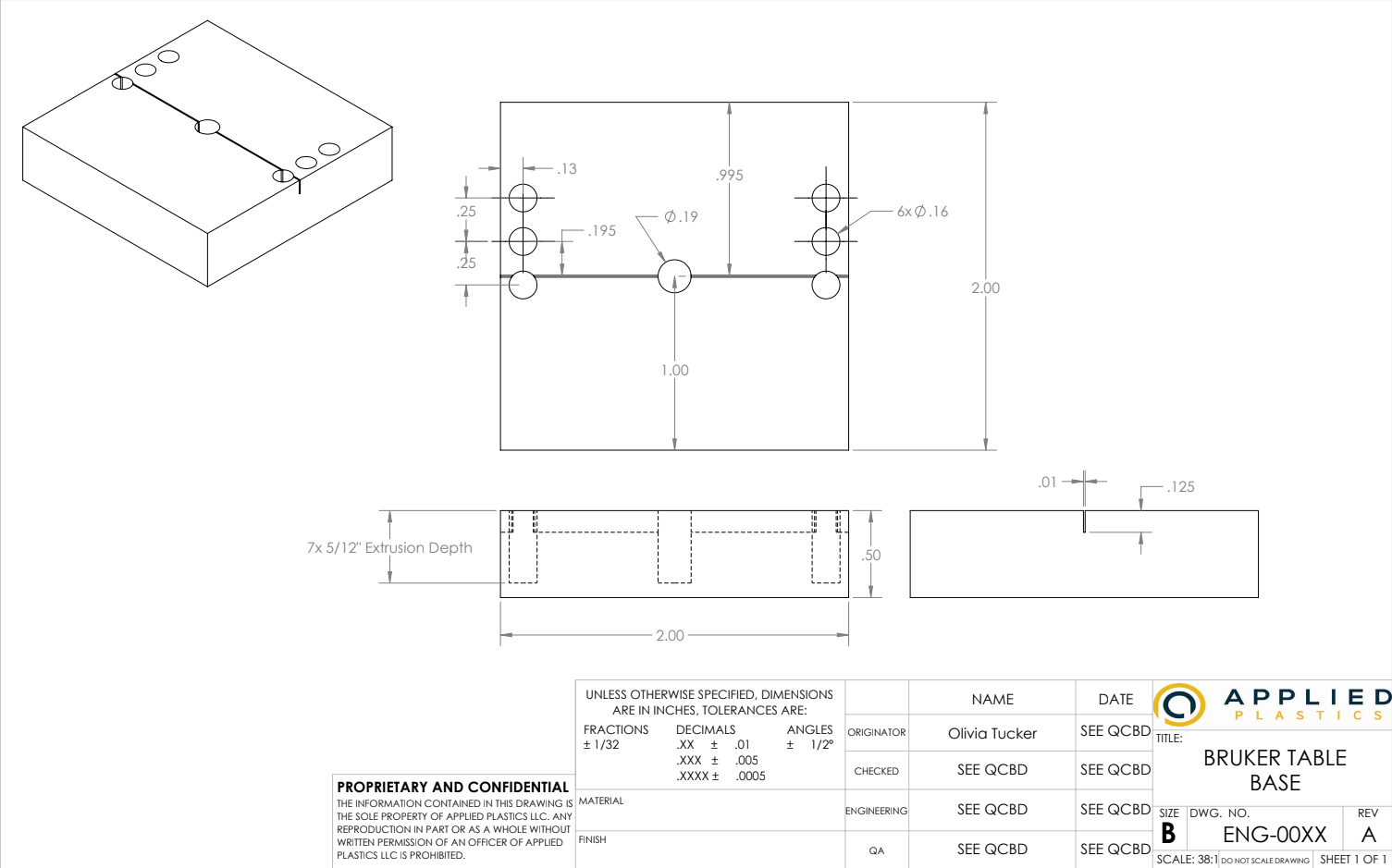

Final Prototype

The final prototype of the applicator included a table and a base with three peg options to give the capability of placing three wires onto the puck. It had enough clearance to make sure the table and placed wire didn't obstruct each other while placing and also that it was low enough in height that the wire didn't accelerate too much on the trip down.

*I have received permission from Applied Plastics to use these images

*I have received permission from Applied Plastics to use these images

Results

In my trial runs, my applicator fixture, being utilized by someone with no prior experience to the Bruker's prep procedure was twice as accurate, in terms of straightness, than when being placed by hand in similar conditions. It was also 33% faster than being placed by hand. The fixture worked so well that it also got adapted to the Anton Paar TRB^3, which also has a similar puck and sample interaction.