Background

PDMS (Polydimethylsiloxane), is known for its cost-efficiency and versatility, is a polymer that has been used for decades. With the recent advancements in technology, the applications for PDMS has has been rapidly expanding . Longstanding applications include microfluidics, biomedical uses, or as a lubricant.

The overall project was a collaboration with UMASS; our part was to simulate ultra-high strain rate expansion of PDMS membrane with a thickness of less than 45 micrometers under sudden expansion of PDMS membrane.

Methodology

PDMS samples of various sizes were to be cured in a convection oven, then to be tested under high strain rate conditions in a Split-Hopkinson Pressure Bar. High strain rate tests often introduce negative factors like inertial effects and stress equilibrium issues. As a form of sanity check we decided to also conduct quasi-static strain rate tests on an Instron machine to operate as comparison points since viscoelastic material's, like PDMS, stress-strain response is often dependent upon the speed of deformation. By comparing quasi-static and high strain rates, data can show the magnitude of rate sensitivity. Quasi-static strain rates and dimensions were selected to be 0.0001 to 1 s^-1 spaced out by an order of magnitude and 0.5 inches in diameter and 1 inch in height, with at least 5 strain rates and 7 samples per strain rate according to ASTM standard D695-26.

Under the guidance of Dr. Salih Duran, my partner and I reviewed various past experiments that related to ours in terms of material type and test method. From there we selected certain aspect ratios and strain rates that displayed effects of interest (shortening the time of stress wave propagation, ensuring uniform wave deformation, and negating the effects of radial and longitudinal inertia).

Aspect ratios selected (unitless): 0.3 and 0.5

Dimensions selected (mm): 1.91/6.35 and 3.18/6.35

High strain rates selected (s^-1): 1000, 2800, and 5500

Quasi-static strain rates selected (s^-1): 0.0001, 0.001, 0.01, 0.1, and 1

Manufacturing

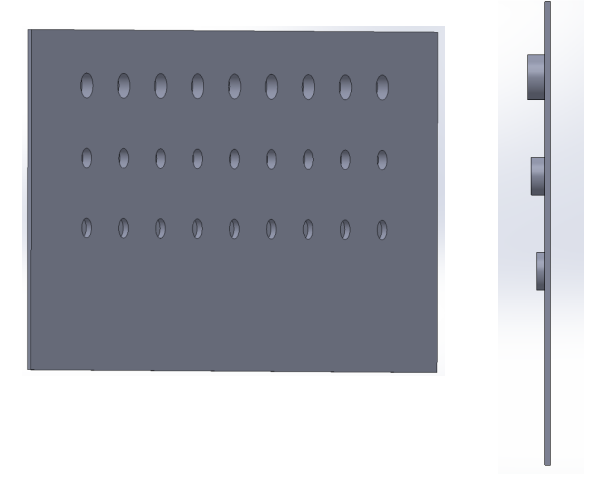

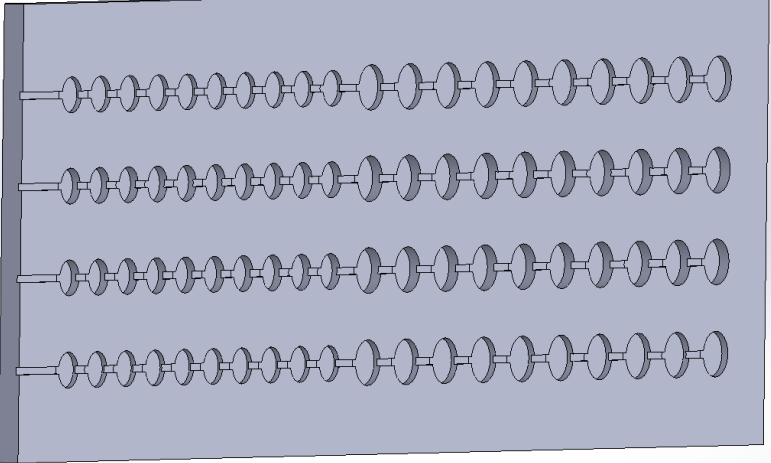

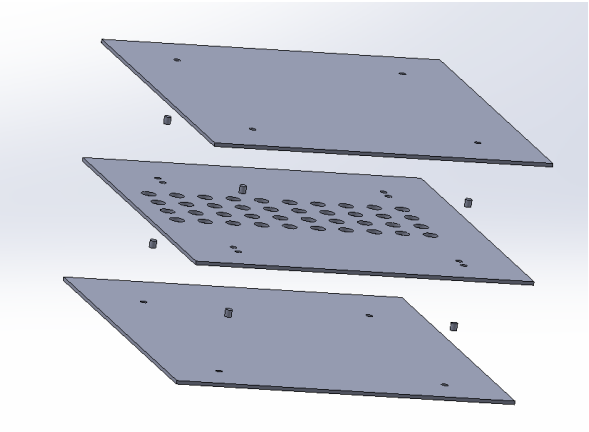

My partner and I were responsible for the design of technical drawings for the molds, through SolidWorks, and formulating samples in the lab. The molds had various design constraints like cost, pressure regulation, removability, ensuring surface roughness of samples, reproducibility, and difficulty to machine.

Our V1 design was a muffin tray inspired design, issues that came with this was removability, reproducibility, and surface roughness.

Our V2 design was an injection mold design, issues that came with this was the difficulty to machine as there was recently a change in machinists at the machine shop.

Our final V3 design was a 3 piece mold, it addressed issues like machining capabilities, surface roughness, and removability.

Bill of Materials (BOM)

The following table lists the components used in the prototypes.

Item | Component | Qty | Items Per Unit | Cost ($) | Total Cost ($) | Supplier |

1 | Multipurpose 6061 | 3 | 1 | 9.38 | 28.14 | McMaster-Carr |

2 | Passivated 18-8 | 1 | 100 | 9.38 | 9.38 | McMaster-Carr |

3 | Multipurpose 6061 | 1 | 1 | 4.90 | 4.90 | McMaster-Carr |

4 | Passivated 18-8 | 1 | 50 | 7.20 | 7.20 | McMaster-Carr |

5 | Polished | 2 | 1 | 15.18 | 30.36 | McMaster-Carr |

6 | Polished | 2 | 1 | 11.73 | 23.46 | McMaster-Carr |

8 | Mil. Spec. 18-8 Stainless Steel Socket Head Screw (10-24 Thread Size, 1-1/2” Long) | 2 | 10 | 8.07 | 16.14 | McMaster-Carr |

9 | Oversized Multipurpose 6061 Aluminum Sheet (1” Thick, 6” x 6”) | 1 | 1 | 51.58 | 51.58 | McMaster-Carr |