Problem Statement

While doing contract work for HFMade 3D printing, a Golden, CO based cycling team with over 200 riders reached out to us with a unique problem they were having with their bikes. Because the electric shifters have strong magnets and cannot be easily adjusted, the team was having issues with the chain bouncing off the front gears when banking corners on European cobblestone race courses. To remedy this, they had envisioned some sort of guard that could attach to the existing screws in the bike frame without interfering with regular bike operation. All of the team was using the same model of bicycle, so there only needed to be one part design that could be printed many times. The parts were to be modeled in Fusion360 and fabricated using a Raise3D Pro2 Plus 3D printer.

Design

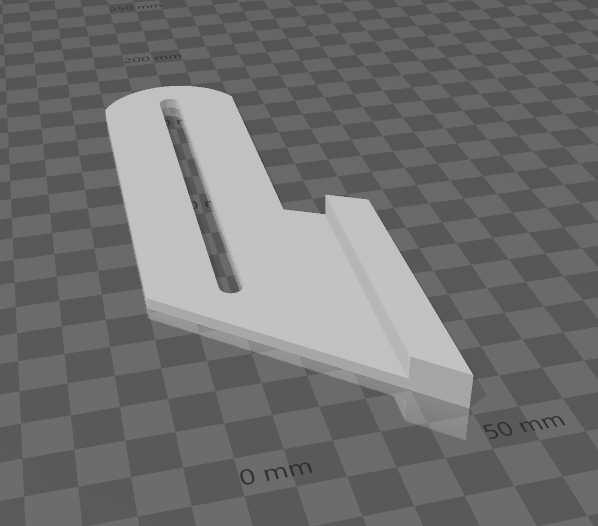

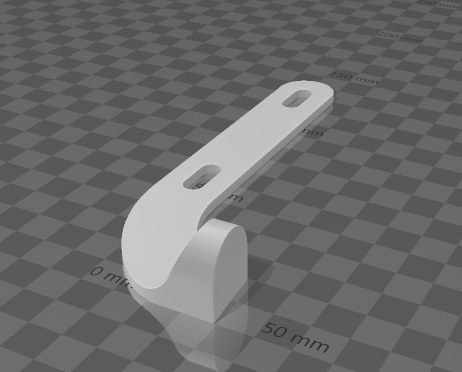

Because the design needs were fairly straightforward, and there was only one scenario to account for, I decided to create 1 design and iterate based on the printed part and client feedback. Using Fusion360, I created the first design and prepared it to print using the Raise3D slicing software. The pictures below show the design of the first and final products created in Fusion360, as well as the printed iterations of the part.

Figure 1: Initial Chain Guard 3D Model

Figure 2: Final Chain Guard 3D Model

Figure 3: Printed Chain Guard Designs

Conclusion

After working with the client through several design iterations, we were able to create a product that fulfilled the needs of the client and was easy to manufacture. Once the design was finalized, I was able to print the part in higher quality to ensure that it could withstand the stress of real racing conditions. This final design was printed for the entire fleet of bikes, over 200 parts printed.