📌 Project Overview

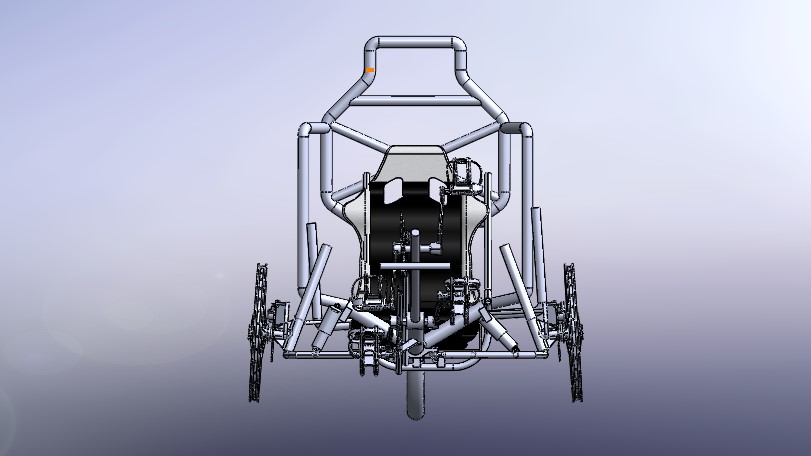

Designed, analyzed, fabricated, and validated a tadpole-configuration Electric Human Powered Vehicle (EHPVC) for the ASME E-FX Competition. The concept integrated pedal-powered motion with an auxiliary electric propulsion system, targeting high efficiency, safety, and manufacturability under event regulations.

👤 Role & Responsibilities

Design & Fabrication Engineer as I contributed to the complete CAD development, simulation, and fabrication of the chassis and powertrain subsystems.

- Collaborated in chassis modeling, RPS design, and aerodynamic profiling using SolidWorks and ANSYS.

- Conducted finite element validation and ensured the fabricated frame matched FEA predictions.

- Participated in battery-motor integration, wiring layout, and drivetrain assembly.

- Assisted in testing, troubleshooting, and on-track evaluation of the hybrid drive and braking system.

- Supported team coordination during design reviews, welding operations, and component sourcing.

🖥️ Design & CAD Development

- Assisted in modelling some parts of the vehicle in SolidWorks, integrating ergonomic positioning, steering geometry, and drivetrain clearances.

- Implemented a 500 W Brushless DCBLDC) hub motor with a 13,000 mAh lithium battery pack for hybrid operation.

- Balanced weight distribution, ground clearance, and wheelbase to achieve optimal handling and stability.

- Incorporated RPS geometry and aerodynamic fairing surfaces adhering to competition constraints.

⚙️ Finite Element Analysis (FEA)

- Performed structural FEA on chassis and RPS using ANSYS to assess deformation and stress under static and rollover conditions.

- Achieved > 5000 N load capacity versus the 2800 N minimum requirement, ensuring high safety margins.

- Optimized tubing layout, weld thickness, and joint placement to minimize stress concentrations and align with fabrication feasibility.

🌬️ Computational Fluid Dynamics (CFD)

- Coordinated with the team members to conduct aerodynamic simulations to evaluate pressure distribution, drag, and lift forces.

- Obtained results of Cd = 4.69 and Cl = 0.1, confirming stable aerodynamic performance.

🛠️ Fabrication

- Contributed to welding and assembly of the chassis using mild-steel tubing, ensuring dimensional accuracy and RPS conformity.

- Integrated drivetrain, steering, and braking subsystems, resolving issues in chain alignment and component clearances.

- Verified structural integrity through visual inspection, static loading, and functional testing.

🔋 Testing & Validation

- Performed on-road testing to evaluate battery discharge rates, pedal assist performance, and braking stability.

- Addressed real-world challenges including chain slack adjustment, ride comfort optimization, and DFM improvements.

- Ensured the vehicle satisfied competition benchmarks for performance and safety.

🏆 Outcome & Achievements

- Secured 1st Place in the ASME E-FX Competition among university-level teams.

- Successfully completed the full engineering cycle — CAD modeling → FEA/CFD → fabrication → testing.

- Enhanced technical proficiency in vehicle dynamics, hybrid power integration, and precision manufacturing.

- Helped in validating the structural and aerodynamic design through real-world operation and competition success.

.png)