This project focused on developing a standardized troubleshooting framework for high-volume manufacturing equipment in SubCom’s Power Conductor department, the busiest area of the facility with ten active production lines. SubCom is one of the world’s leading providers of undersea fiber optic cable systems, where unplanned downtime has significant cost and schedule impact.

The primary focus was the seam welder, a critical process step and a major contributor to recurring downtime. Prior to this work, troubleshooting relied heavily on undocumented technician experience, leading to inconsistent diagnostics across shifts and extended recovery times. The goal was to capture this tribal knowledge and convert it into a structured, repeatable diagnostic system usable directly on the production floor.

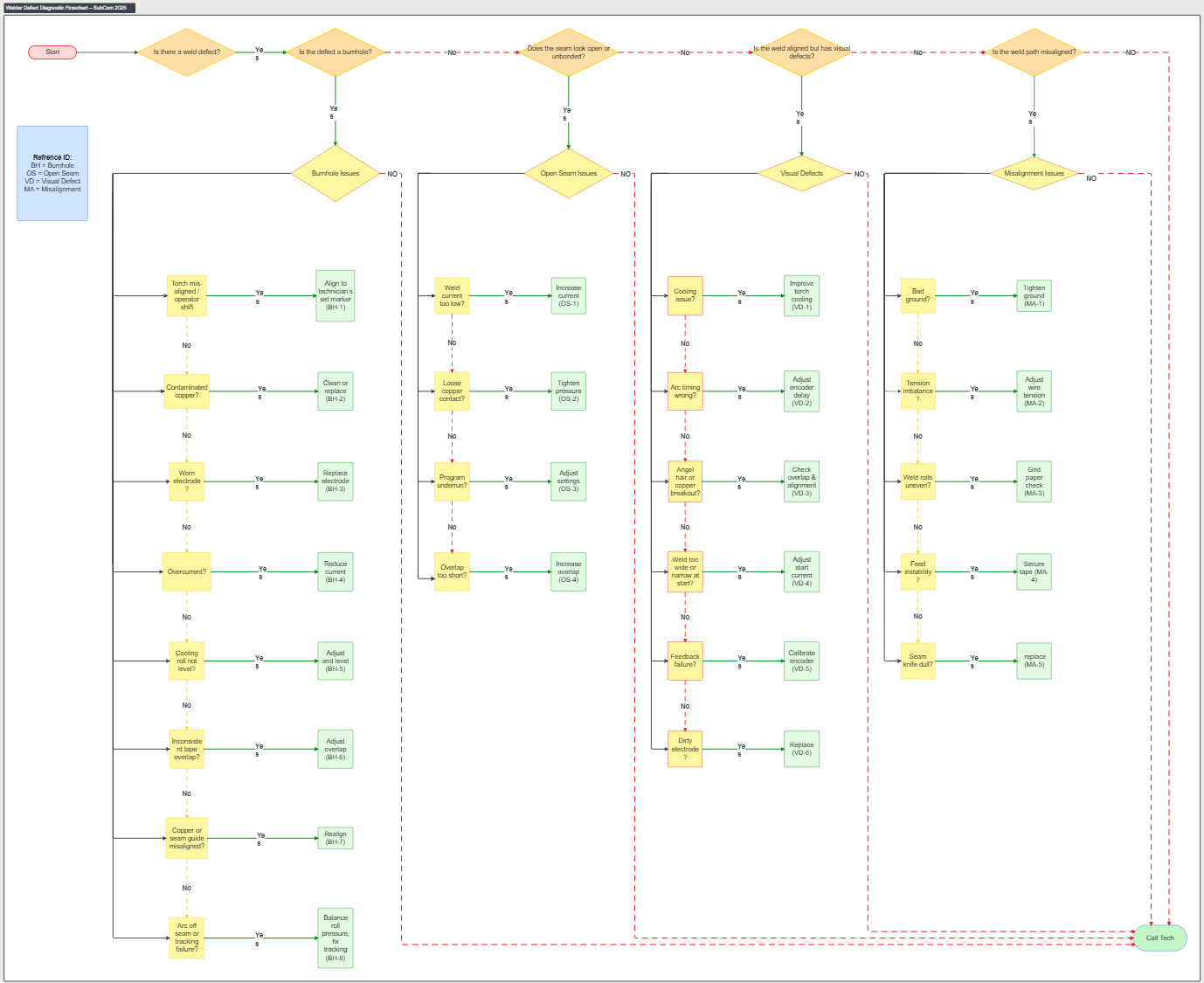

The diagnostic framework was developed through direct observation of live production issues, review of historical line logs, and technical validation with senior technicians and process engineers. Only failure modes that were both common and realistically diagnosable in production were included. Defects were categorized into four primary classes: Burnhole, Open Seam, Visual Defect, and Misalignment.

A comprehensive decision-tree flowchart was created using symptom-driven yes/no logic to guide technicians toward the most likely root cause. Each decision node maps to a unique reference ID, allowing users to transition seamlessly from high-level diagnosis to deeper technical guidance when needed.

To support the flowchart, a companion reference guide was developed and deployed. Each reference entry documents the failure mechanism, corrective action, verification steps, and relevant production notes based on real observations from the manufacturing floor. This two-layer structure enables fast troubleshooting while preserving technical depth and consistency across operators.

The system was designed around real production constraints, emphasizing measurable adjustments such as alignment, weld current, overlap, timing, cooling, grounding, and tension rather than abstract recommendations. Issues not resolved within documented paths are clearly identified as new failure modes, enabling improved tracking and long-term process improvement.

All supporting materials, including the full diagnostic flowchart and reference guide, are included below as attachments.