Sep 2025 - Dec-2025

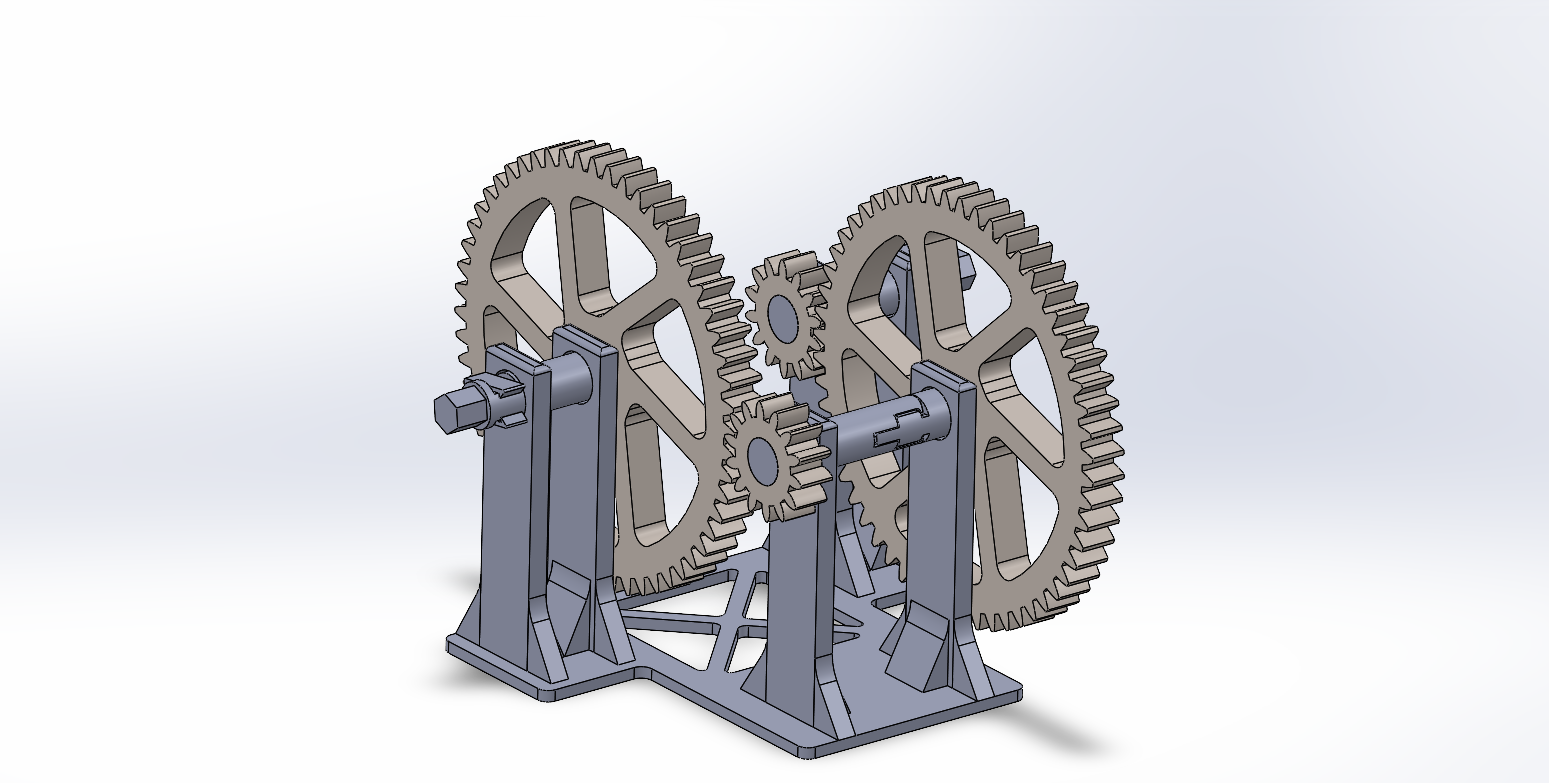

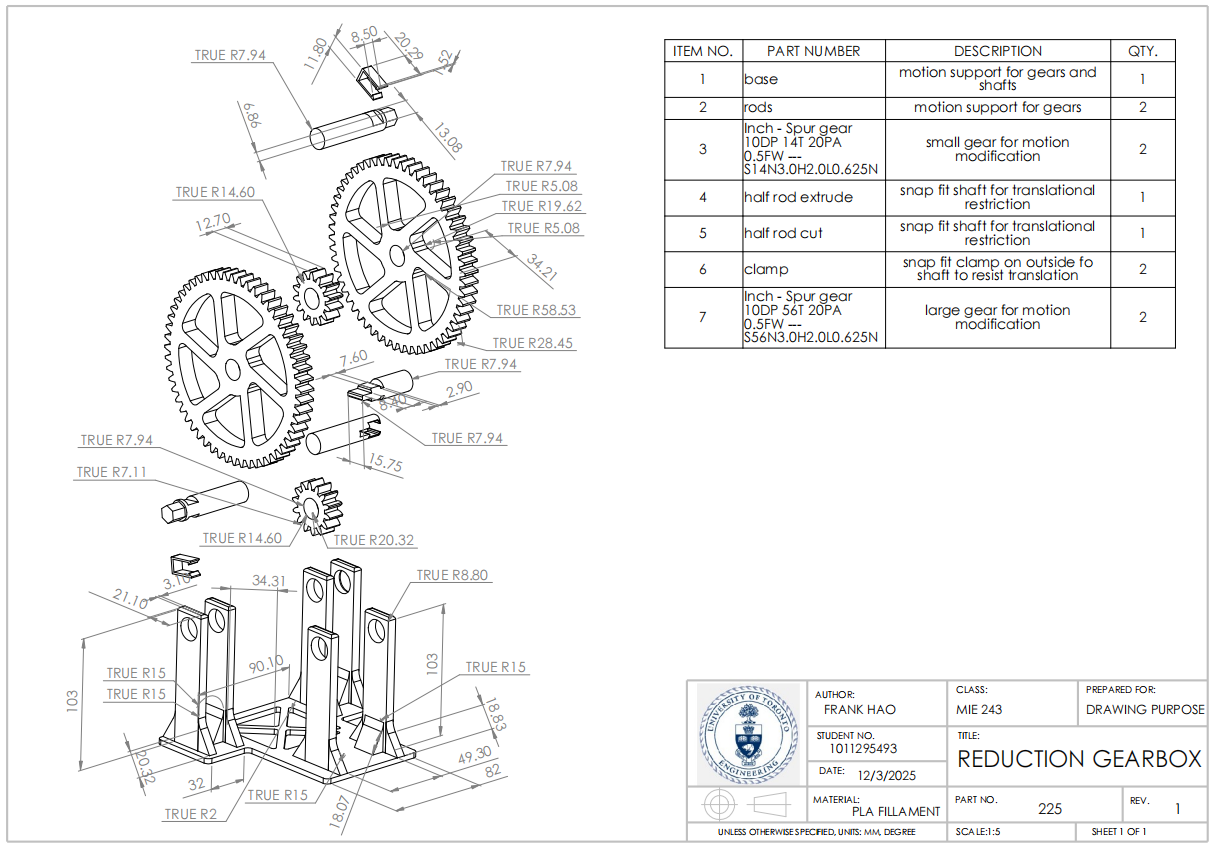

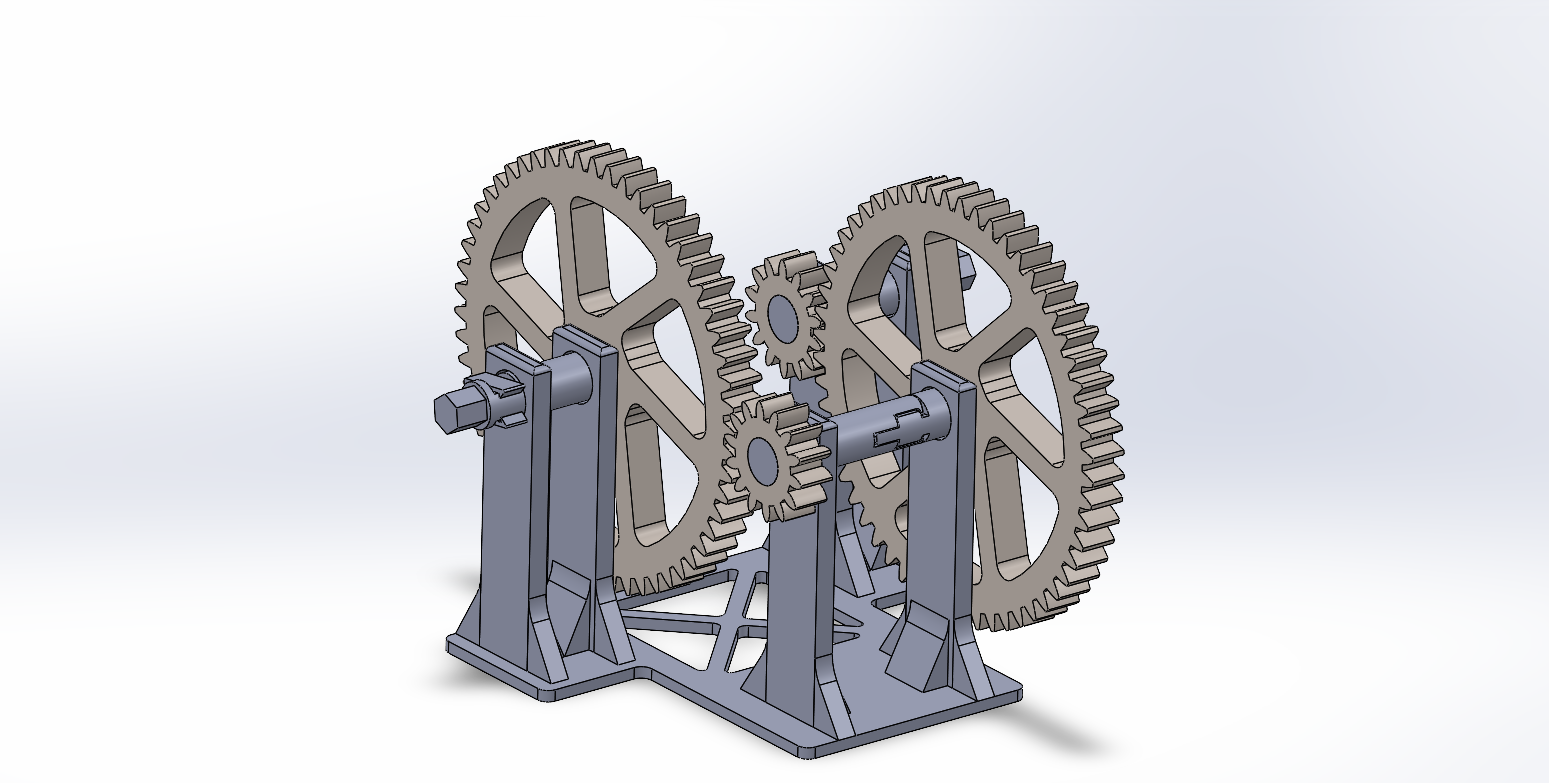

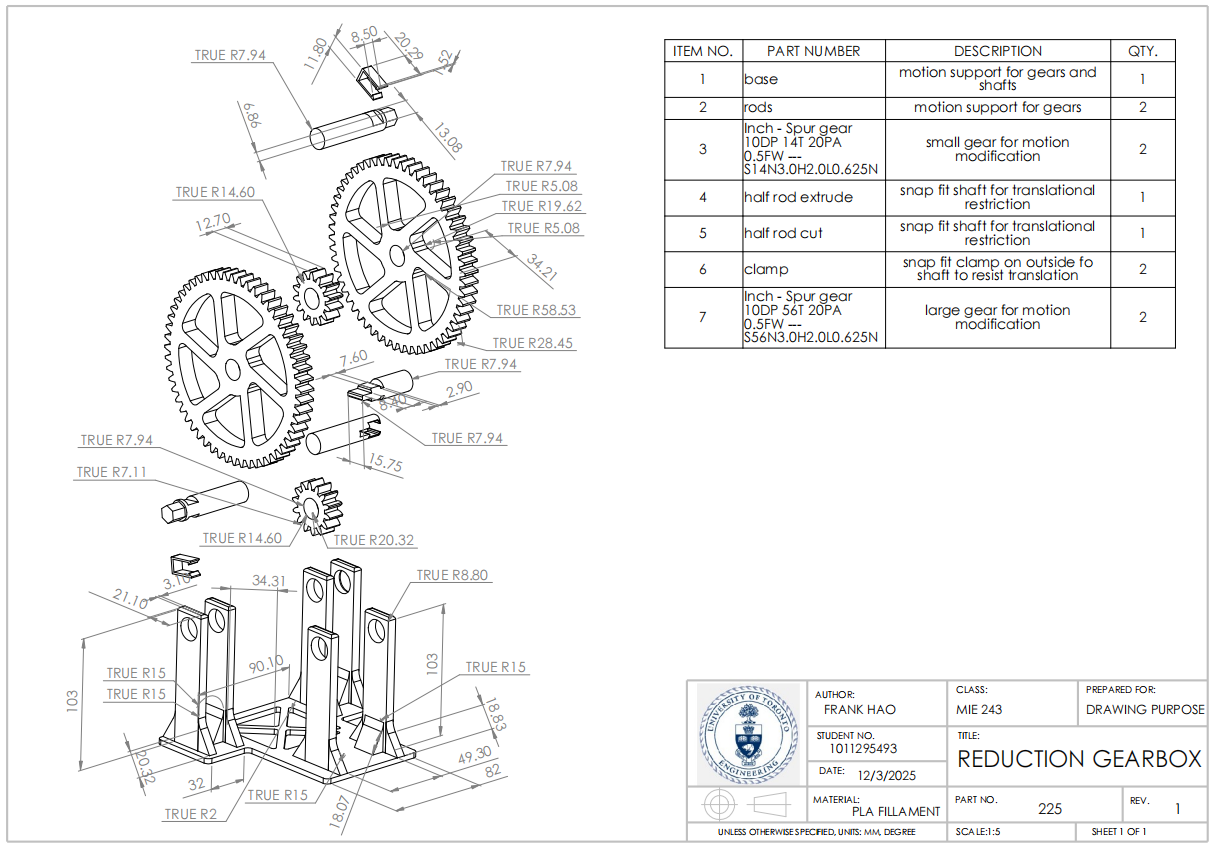

• Designed a 16:1 reduction gearbox in SolidWorks, creating a fully-mated assembly featuring spur gear geometry, shaft interfaces, bearing seats, and housing constraints appropriate for introductory machine design instruction.

• Fabricated a working prototype through FDM 3D printing, selecting print parameters, materials, and tolerances to ensure proper meshing, smooth rotation, and structural stability under hand-operated loads.

• Analyzed gear tooth geometry, backlash, and contact ratios to ensure reliable torque transmission and minimize wear points in a polymer-based prototype.

• Optimized gear and housing geometry for additive manufacturing by adjusting fillets, wall thicknesses, overhang angles, and support structures to reduce print failures and improve dimensional accuracy.

• Coordinated with laboratory instructors and workshop staff to align the gearbox design with course learning objectives and machining safety constraints.

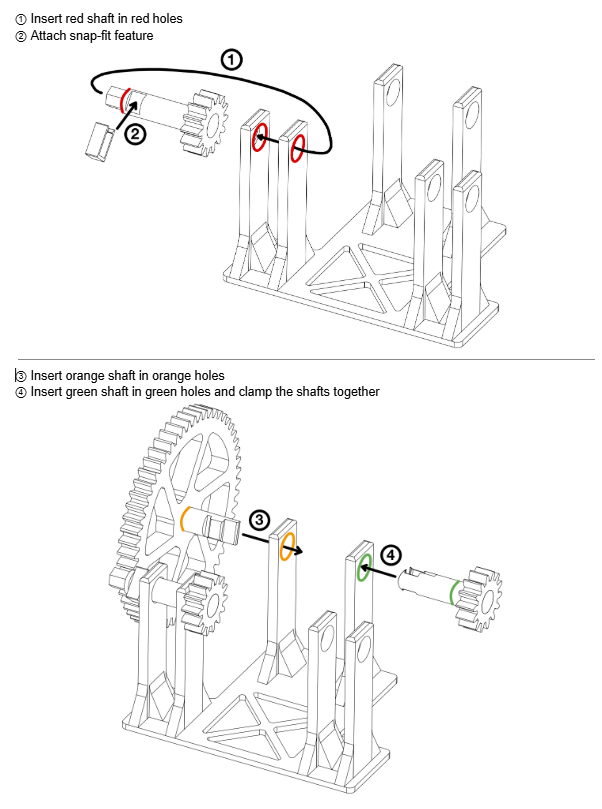

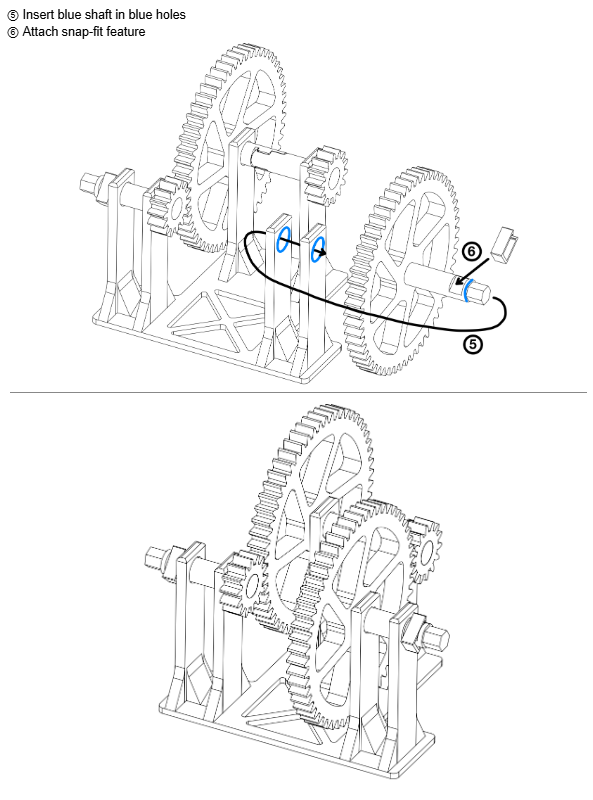

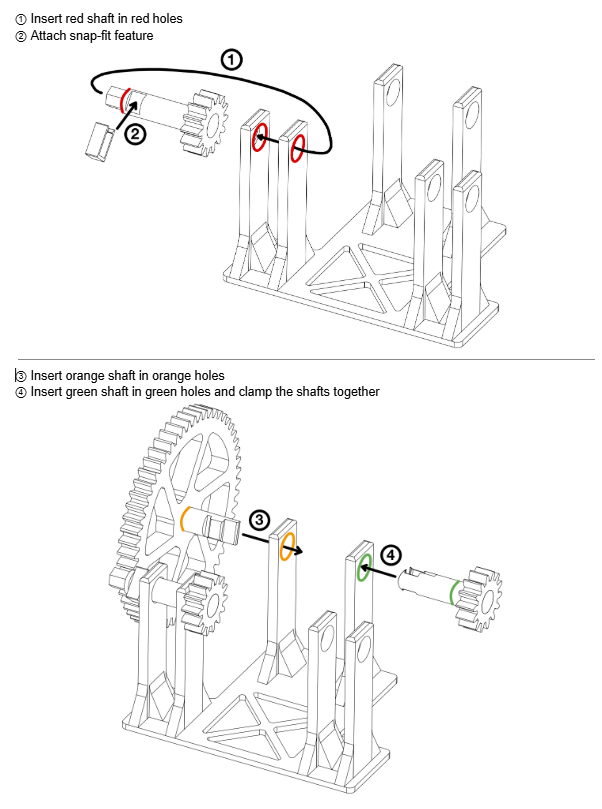

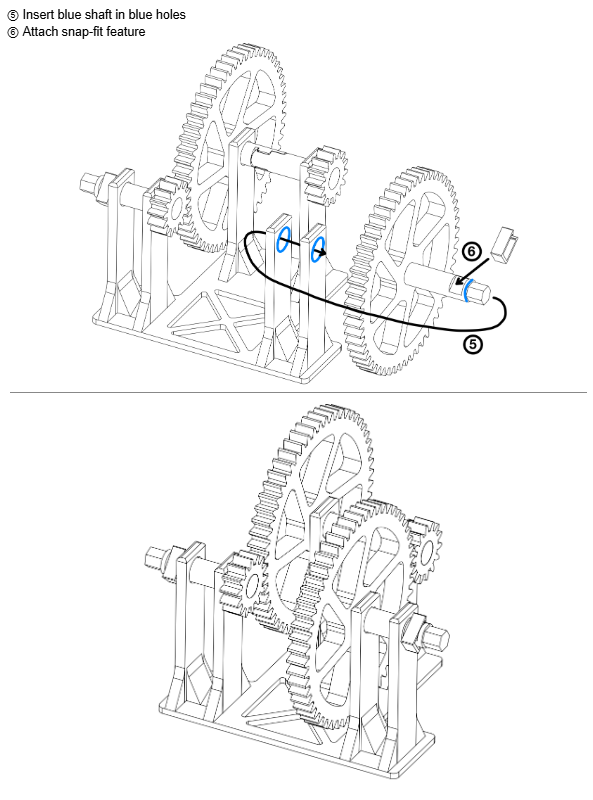

• Prepared technical diagrams, assembly instructions, and explanatory materials to support student learning on gearing fundamentals, tolerances, and design-for-printability principles.

• Delivered a functional prototype that demonstrated smooth torque reduction and reliable mechanical engagement, enhancing hands-on understanding of transmission systems for students.

• Reduced expected print defects and assembly issues through manufacturability-focused design revisions, enabling consistent reproduction of the gearbox for instructional use.