Aero-Engine Speed Reducer – Mechanical Design B (University of Birmingham)

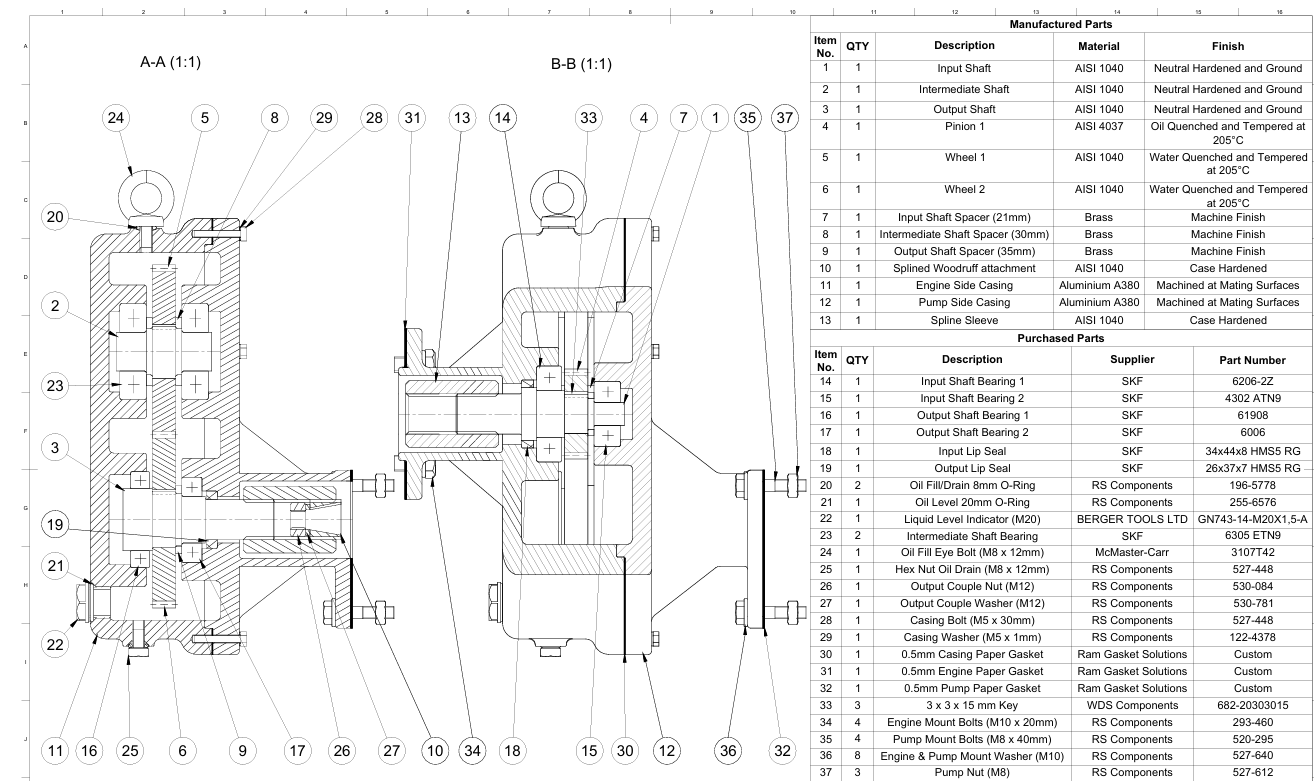

Collaborated in a four-person team to design a compact, efficient gearbox for an aero-engine PTO system delivering 25 L/min of oil at 150 bar. Used Romax Concept to optimise a three-stage spur gear train and performed shaft fatigue and bearing life analysis using Soderberg criteria. Implemented splash lubrication, selected appropriate materials and SKF bearings, and applied DFMA principles, reducing part count by 38% and improving assembly efficiency from 48% to 72%. Produced detailed design validation, cost analysis, and maintenance schedules, ensuring manufacturability, durability, and performance for high-volume production.

BOM

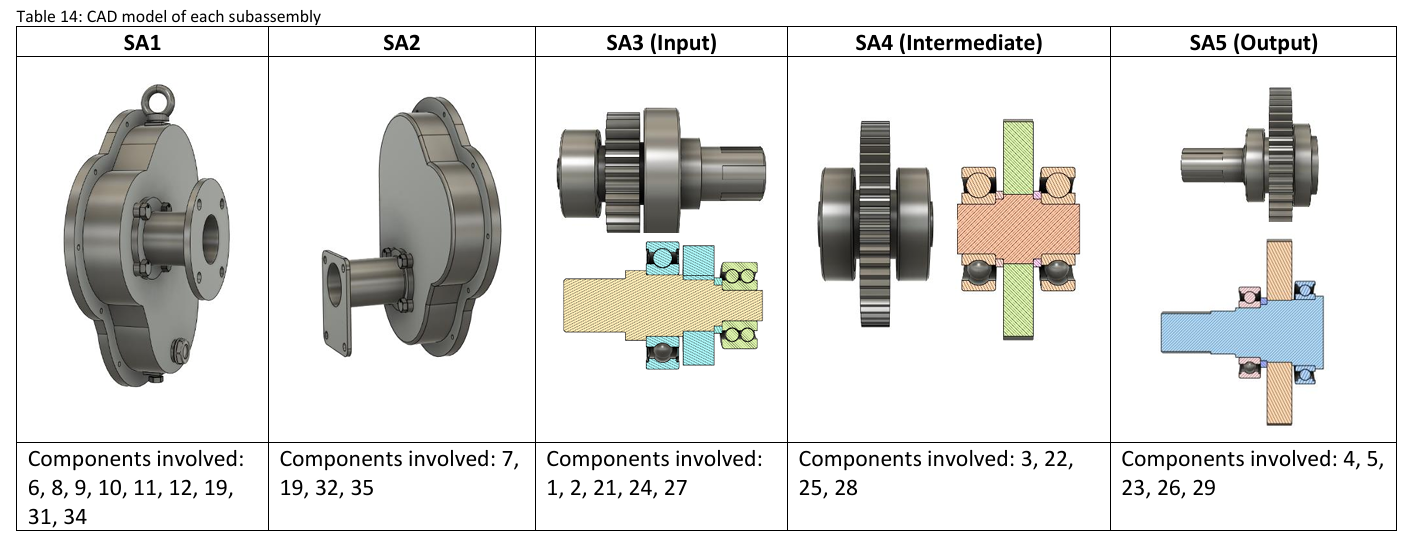

Sub Assemblies