Abstract

The demand for lightweight materials with superior mechanical properties is growing across many industries, from aerospace to biomedical. Auxetic structures, which expand laterally when stretched axially, have excellent mechanical properties, providing a unique solution to this demand. While conventional auxetic structures have been extensively studied, hollow auxetic structures have been largely unexplored, limiting the potential in lightweight engineering applications. A novel hollow auxetic unit cell has been designed, optimised, and mechanically tested to have a high negative Poisson’s ratio (NPR) and compressive strength.

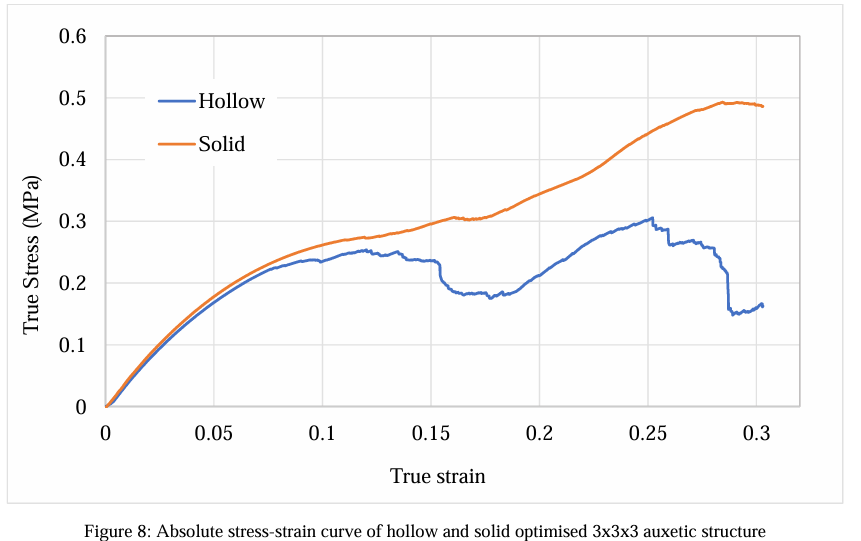

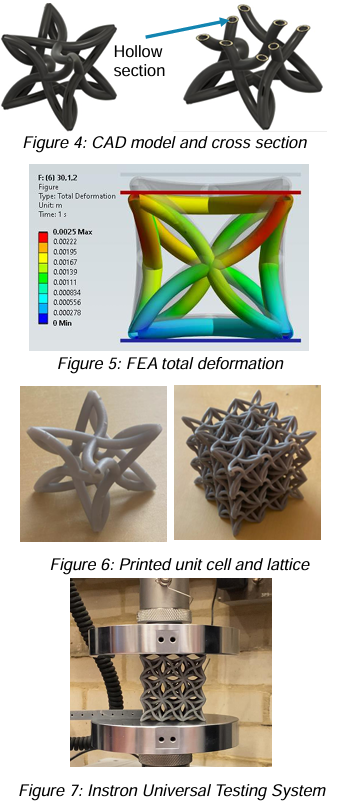

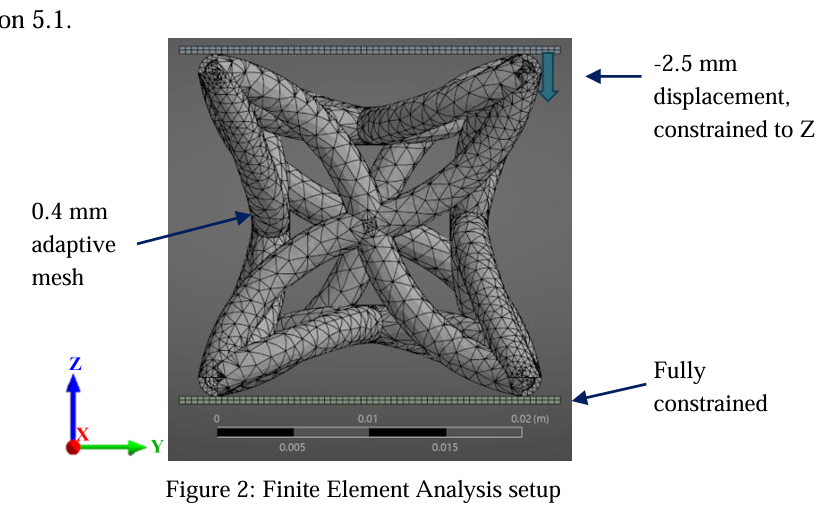

A novel unit cell was created, including re-entrant and chiral auxetic mechanisms, with hollow struts, each defining a key design parameter. Design of experiment (DOE) and finite element analysis (FEA) were used to find the optimum combination of these parameters for maximum NPR. Stereolithography (SLA) printing was used to print the unit cells arrayed into a 3×3×3 structure. Compression testing revealed that the NPR of the structure was significantly less negative than the unit cell. Hollow struts, compared to solid, improved specific Young’s modulus and specific peak compressive strength by 70% and 5%, respectively. The novel design displays excellent lightweight stiffness and strength, but auxetic performance suffers as the unit cell is arrayed into a 3×3×3 structure.

Visual Representation of Project Stages

FEA Setup

Results