The Northrop Grumman Collaboration Project (NGCP) is a joint research and development effort between Cal Poly San Luis Obispo (CPSLO) and Cal Poly Pomona (CPP) to design and demonstrate a multi-vehicle autonomous system for search and rescue missions. Funded by Northrop Grumman, the 2025–2026 mission centers on coordinating unmanned air and ground vehicles to locate and recover survivors during disaster scenarios such as floods. CPSLO is responsible for developing the Med-Evac Aircraft (MEA) — an unmanned aerial vehicle dedicated to autonomous survivor transportation — as part of an integrated system that communicates through a shared ground control station. Together with CPP’s vehicles, the CPSLO MEA contributes to a unified, fully autonomous rescue operation emphasizing cross-campus collaboration, systems integration, and mission-level functionality.

One of the main requirements of CPSLO's MEA is to have the capability to autonomously and safely release a preloaded payload, or rescue victim, at a desired location. Within this effort, I am a member of the payload system design team, tasked with finding the most optimal way to release the payload. The derived requirements for our design include:

- Have minimal effect on aerodynamics of MEA

- Keep power requirements to a minimum

- Keep weight of system below 3 pounds

- Prioritize repeatability

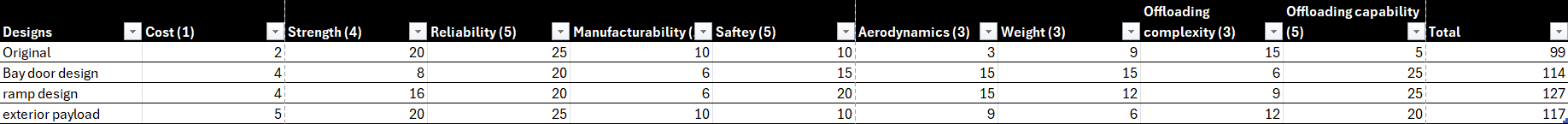

After multiple design iterations and concept evaluations using a Pugh decision matrix, our team selected a design concept — originally proposed by me — that integrates the payload mechanism within the fuselage. The final design employs a horizontal rack-and-pinion system to actuate dual bay doors on the underside of the fuselage, providing an efficient, lightweight, and repeatable solution that satisfies all project requirements.

Future Work

This project is still in its early stages and will continue through the remainder of the academic year. Upcoming tasks include finalizing the payload system design and developing a second functional prototype to validate the chosen concept. Once the payload mechanism is approved, the mechanical team’s efforts will shift toward fabrication of the full drone airframe.

This next phase will begin with creating a detailed solid body model in Fusion 360, derived from the shell geometry provided by the aerodynamics team. The finalized model will serve as the basis for structural layout, component placement, internal routing, and interface definitions for all mechanical subsystems, including the payload apparatus.

Using this model, the team will fabricate the airframe using carbon fiber composite layups in the Cal Poly SLO Composites Lab. This process includes producing molds, preparing layup schedules, curing components, and performing post-processing such as trimming and bonding of subassemblies. Once the composite fuselage and wing structures are complete, the final payload deployment mechanism will be fabricated, fitted, and integrated into the airframe.

Overall, this full design–fabrication–integration cycle is expected to occupy the majority of the winter quarter, culminating in initial fit checks, system bring-up, and preparation for flight testing in the spring.