Details on nyuad.space website

Team and Role

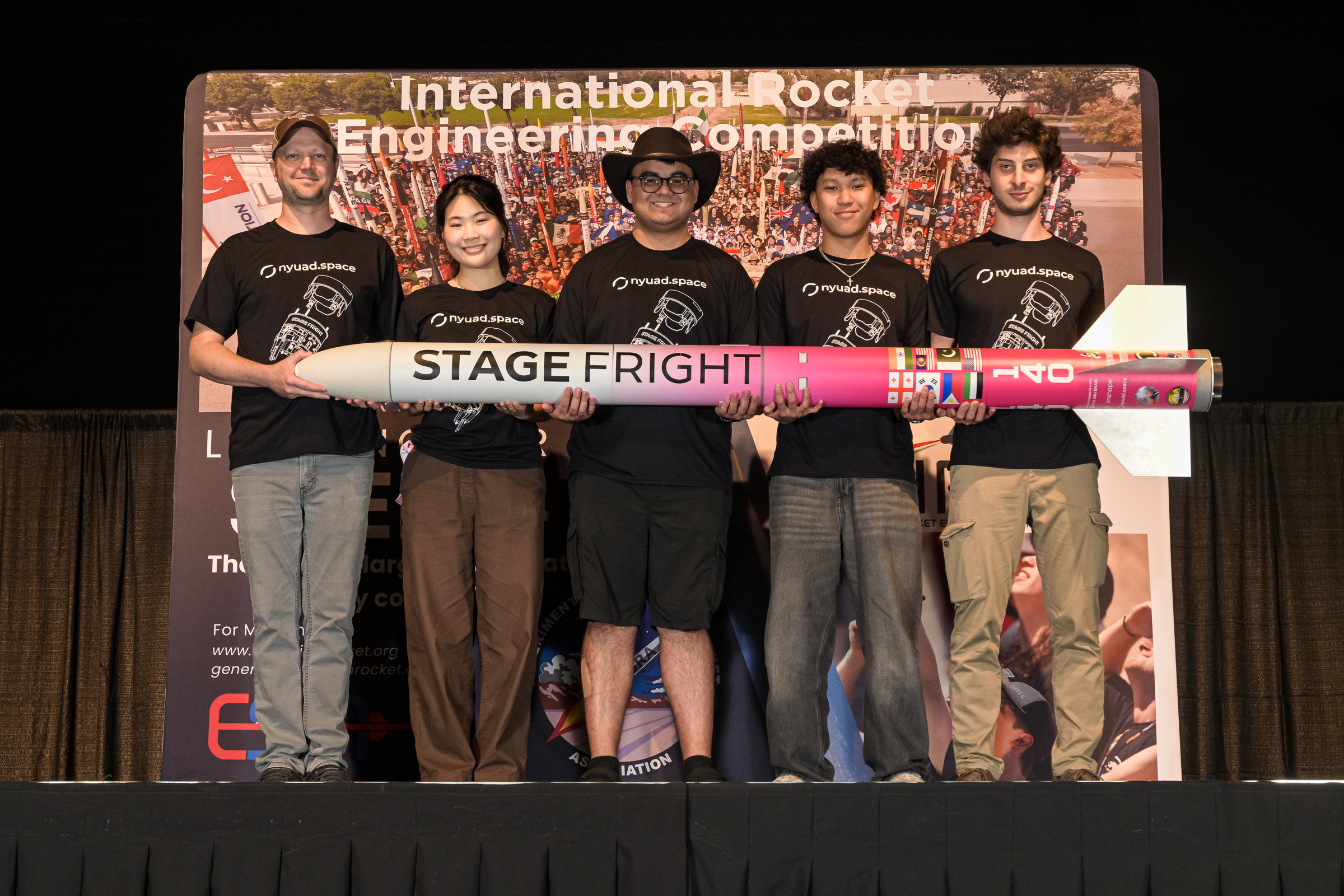

Our team consisted of four members, which meant that everyone was involved in both the conceptual development and the technical implementation. We constantly reviewed each other’s designs and cross-checked every subsystem to ensure proper integration.

My Contributions

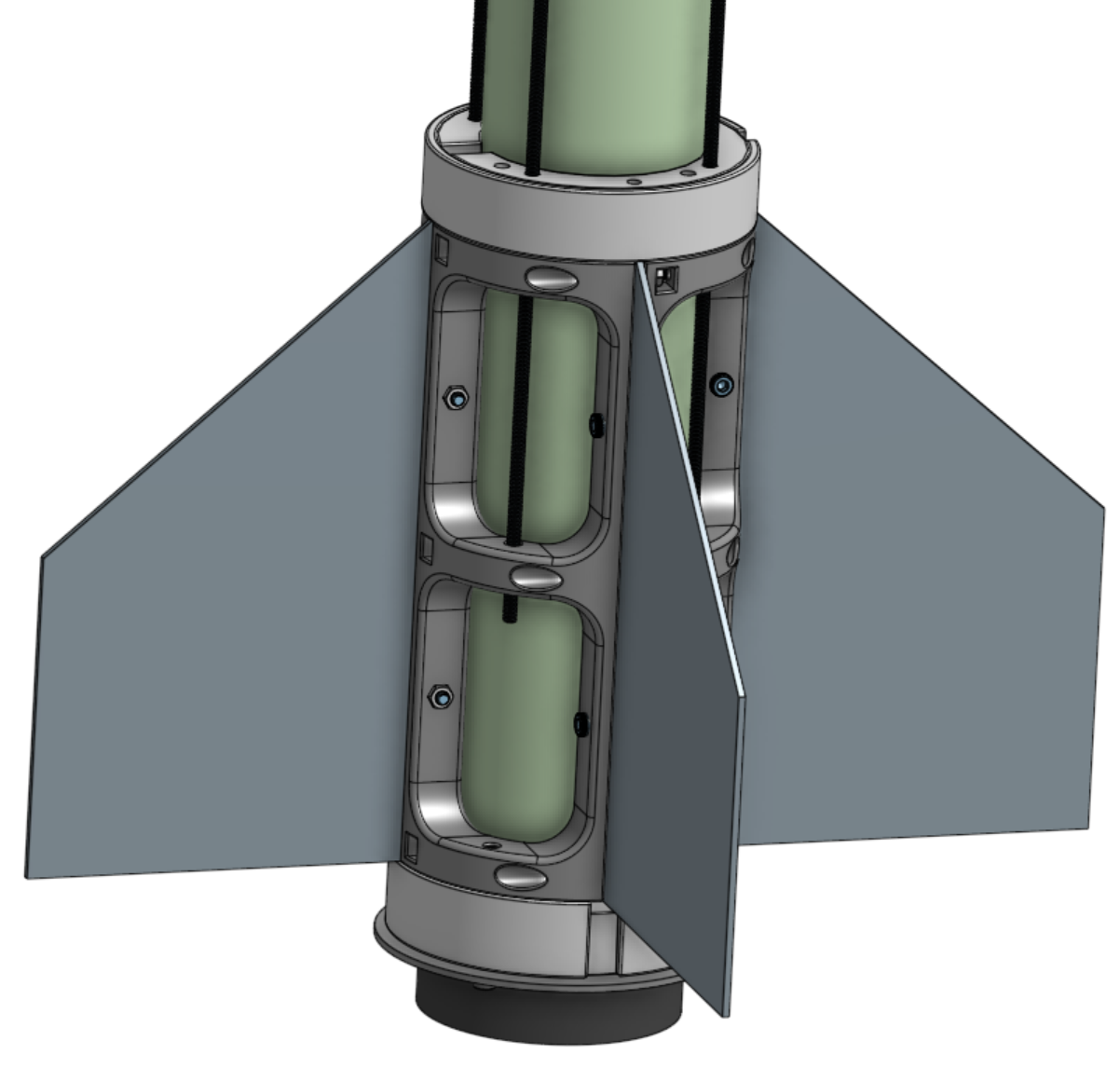

I developed an improved release mechanism for staging the rocket, based on the 2023 design. After many group discussions comparing hold-down and release mechanisms like over-center and compliant systems, we decided to adapt the previous hinge design but fit it into a one-inch annulus using steel cables and linear actuators. This kept the center space open for the staged engine. I completed the tensioning mechanism, which addressed a major issue faced by the 2023 team—tightening a nut through a small cutout. My redesigned coupler section used two accessible screws on each side that could be fastened with a drill and a 90° converter, making the process much faster and more reliable.

I also improved the fin can design, reducing it from 12 parts to 4 by combining certain sections. While this didn’t significantly reduce material weight, it cut down on the number of fasteners, simplifying assembly and slightly reducing total mass.

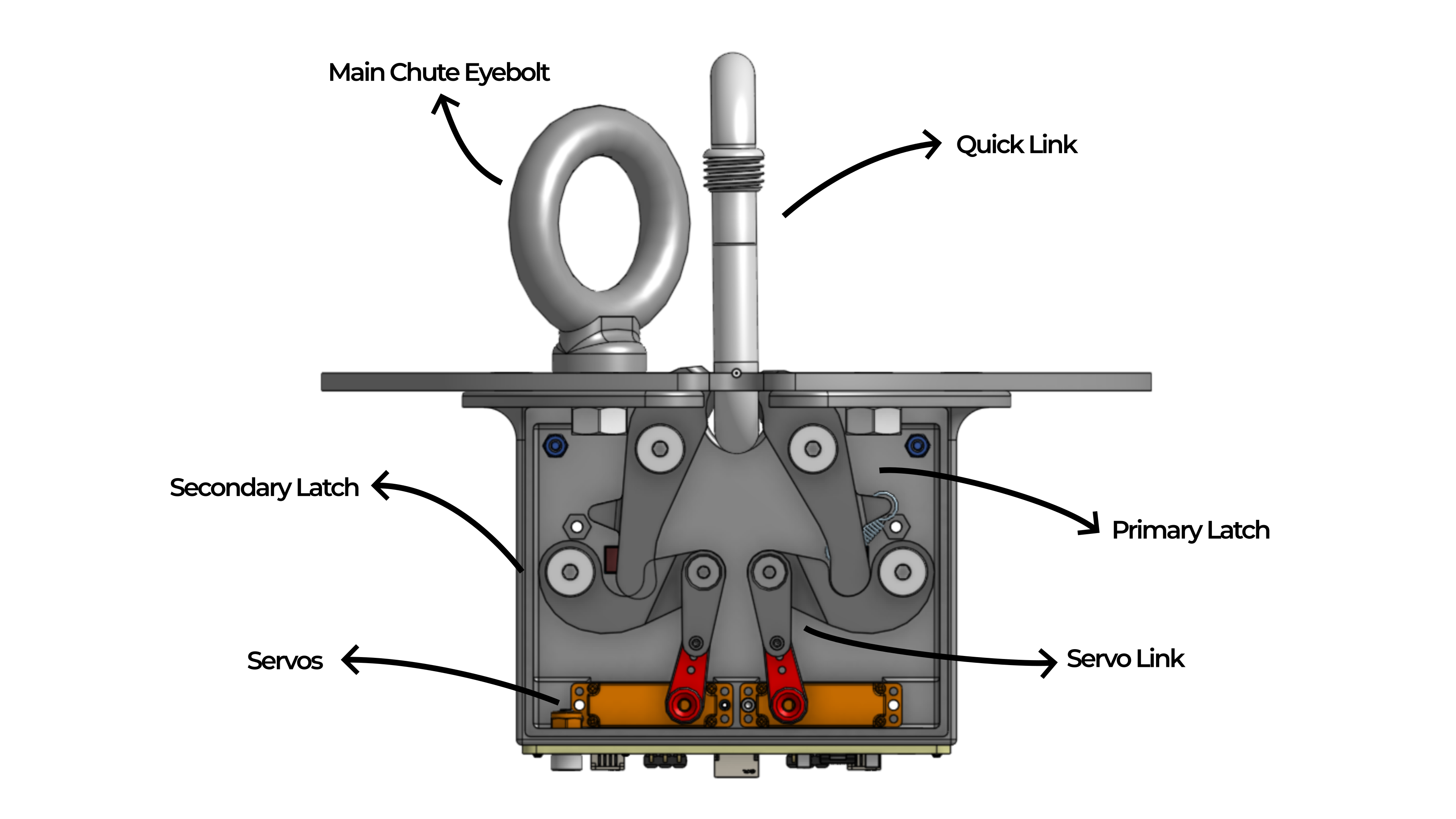

For the recovery system, I redesigned the PRM (Parachute Release Mechanism) for the main parachute. It was mechanically similar to the 2023 version, but I scaled it down for our new load requirements and available space. I ran simulations to confirm safety margins and functionality.

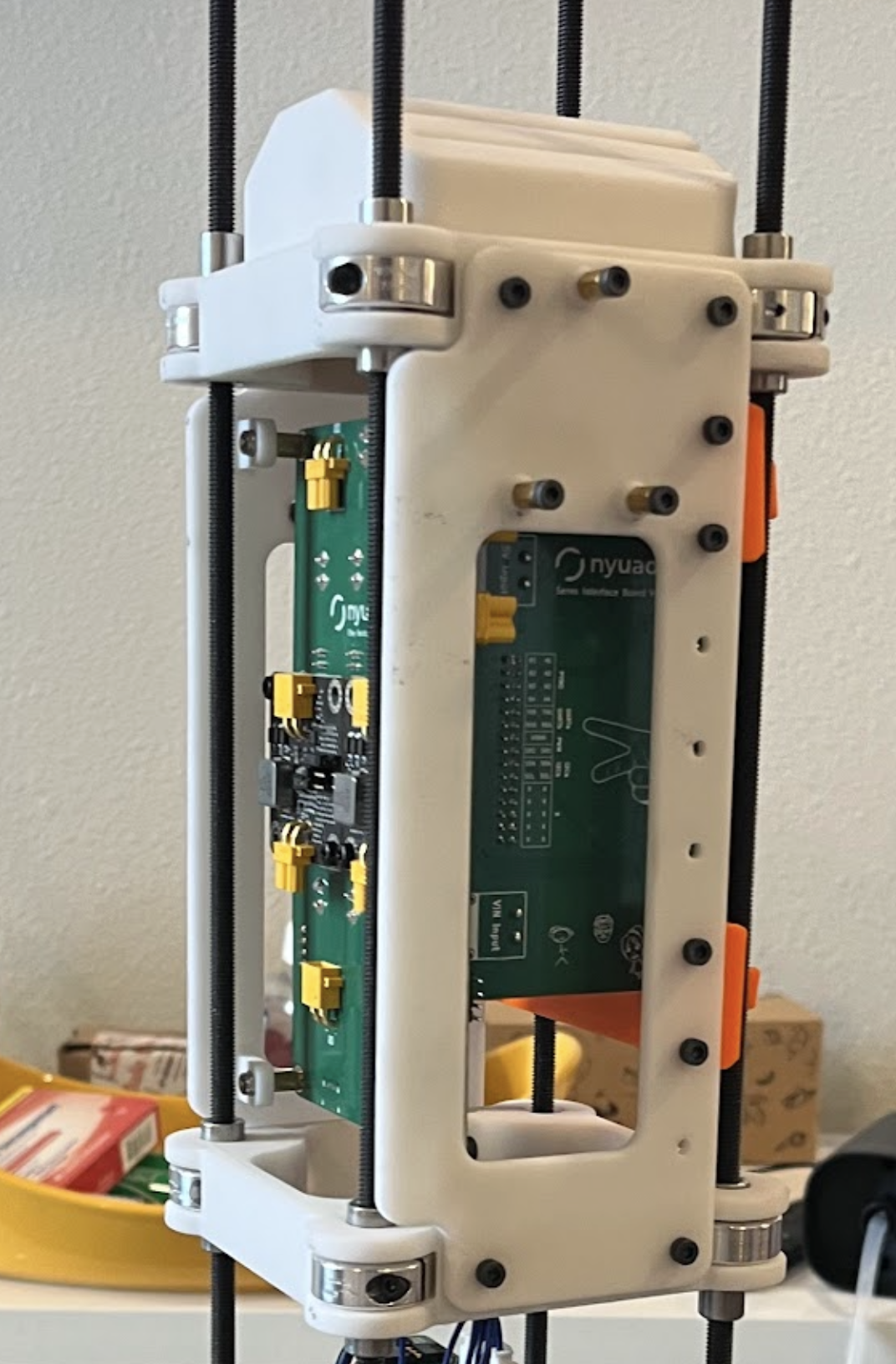

I designed the Avionics Box, focusing on a modular structure that allowed hot-swappable boards. My contribution was the mounting system, while two other teammates developed the circuit boards.

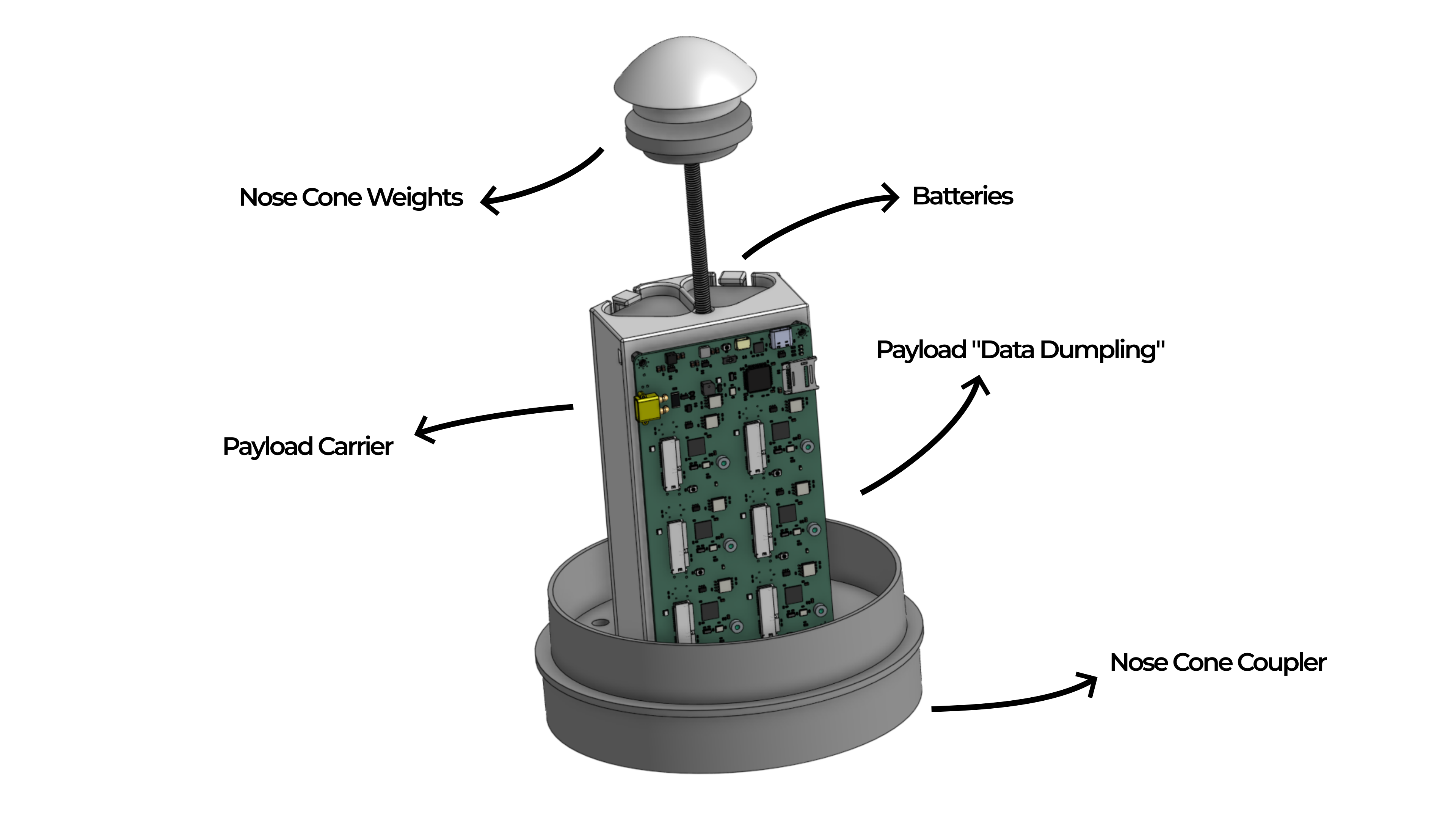

I also designed the payload holder, placing it in the nosecone to improve rocket stability while meeting the weight and size constraints of the competition. The nosecone itself was designed for quick removal to allow easy troubleshooting during testing and launch preparation.

---2025-06-13---14.22.43%20(yooni).png)

Lastly, I created detailed engineering drawings to communicate precise dimensions and custom cuts to tube manufacturers.

The Team: