Problem Statement

Design a new end of arm tool for rocker clip pick and place to replace the generalized tool currently on the robot that consistently misses clips during insertion.

Current EOAT Design

The current end of arm tool uses vacuum to grab the top of the clip; however, the rocker clips have a rectangular base meaning they can still pivot out of place as shown in the image above. This tool works for the common clip because they are round and symmetrical so it does not matter if they spin, so to solve this issue, I am designing an entirely new tool for the rocker clips that will self-change change using quick change modules.

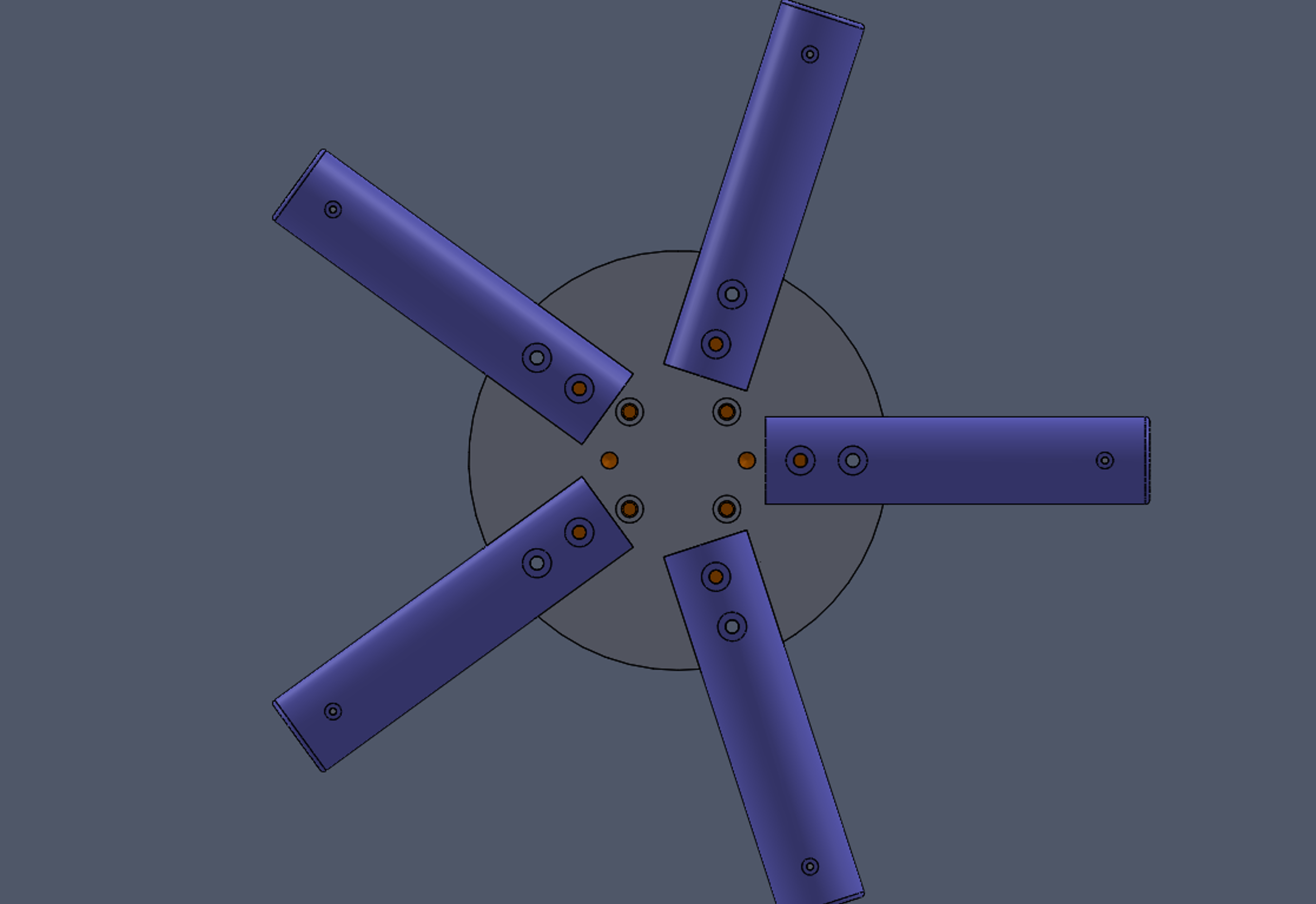

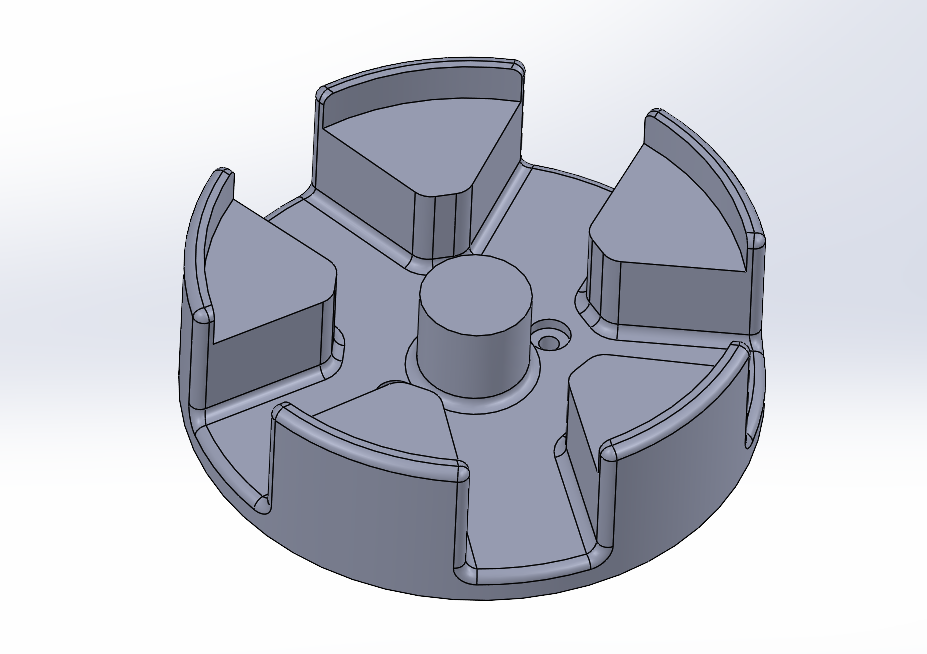

Rocker Clip EOAT Design

For my design, I utilized a rectangular pocket in the top of the clip that can be stabbed into to grab the clip. I am going for a similar spindle type design because it works well for the current EOAT.

Everything will be machined so it holds up overtime but to ensure all of my tolerances are correct, I printed a smaller prototype module.

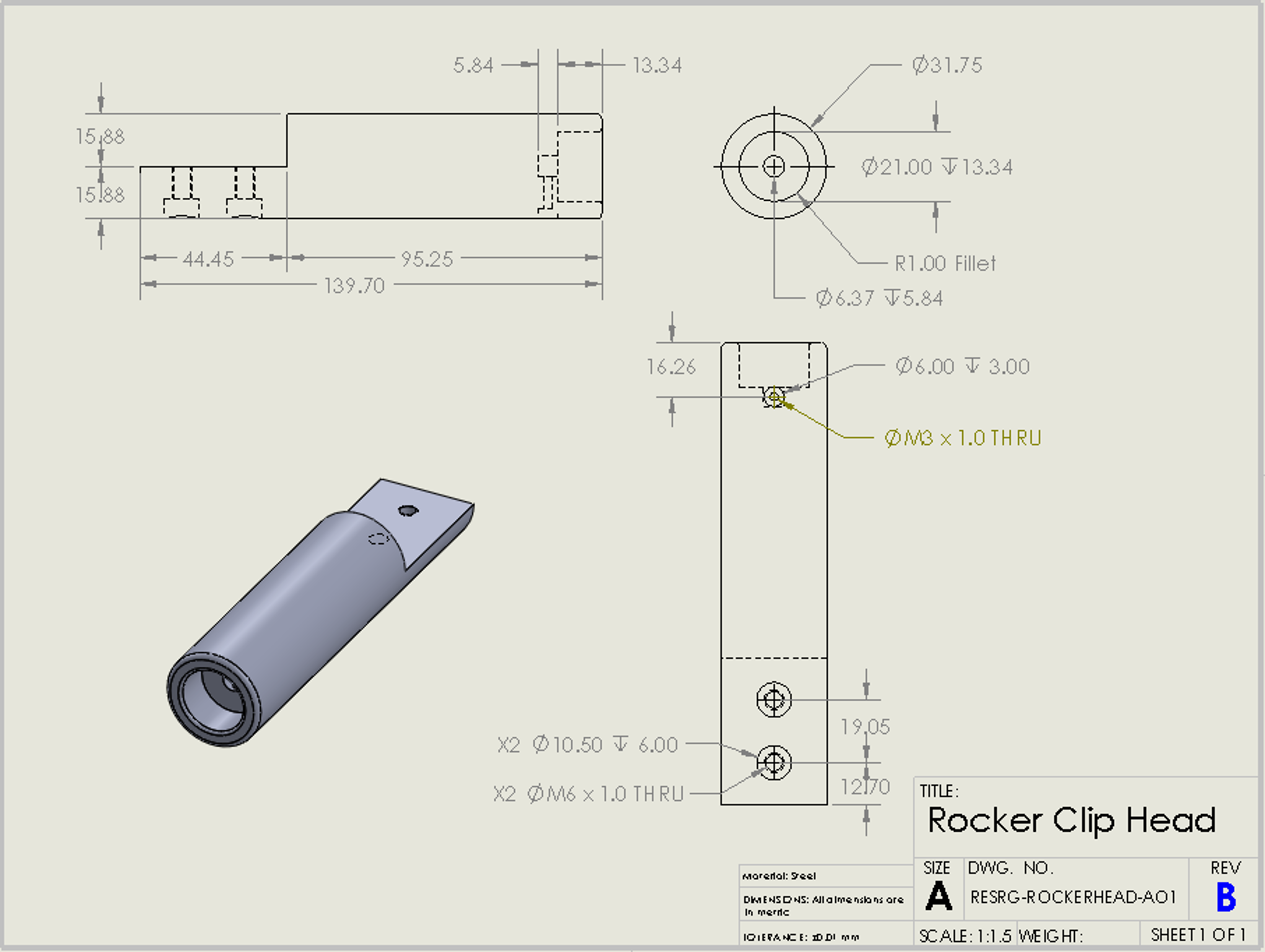

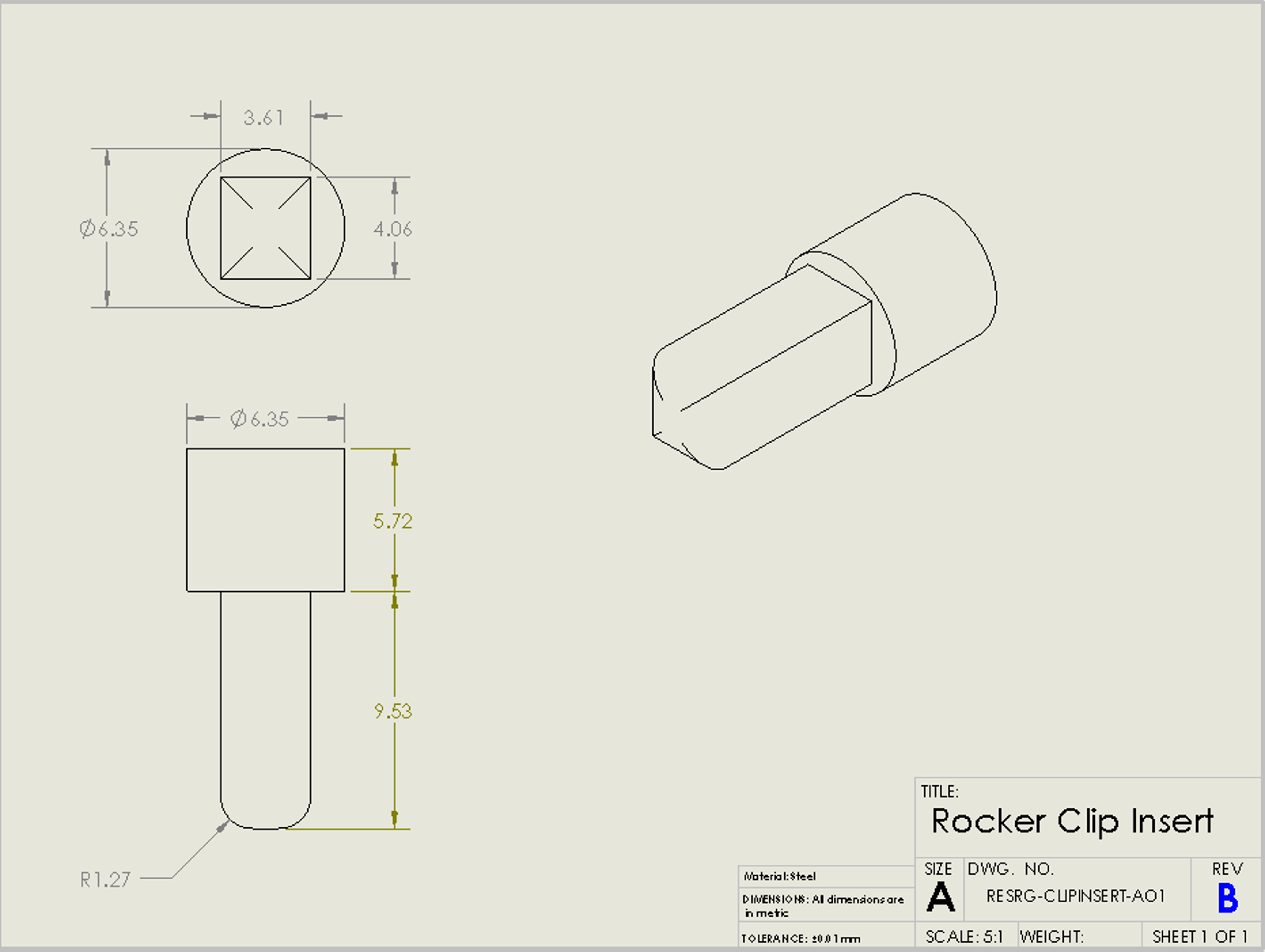

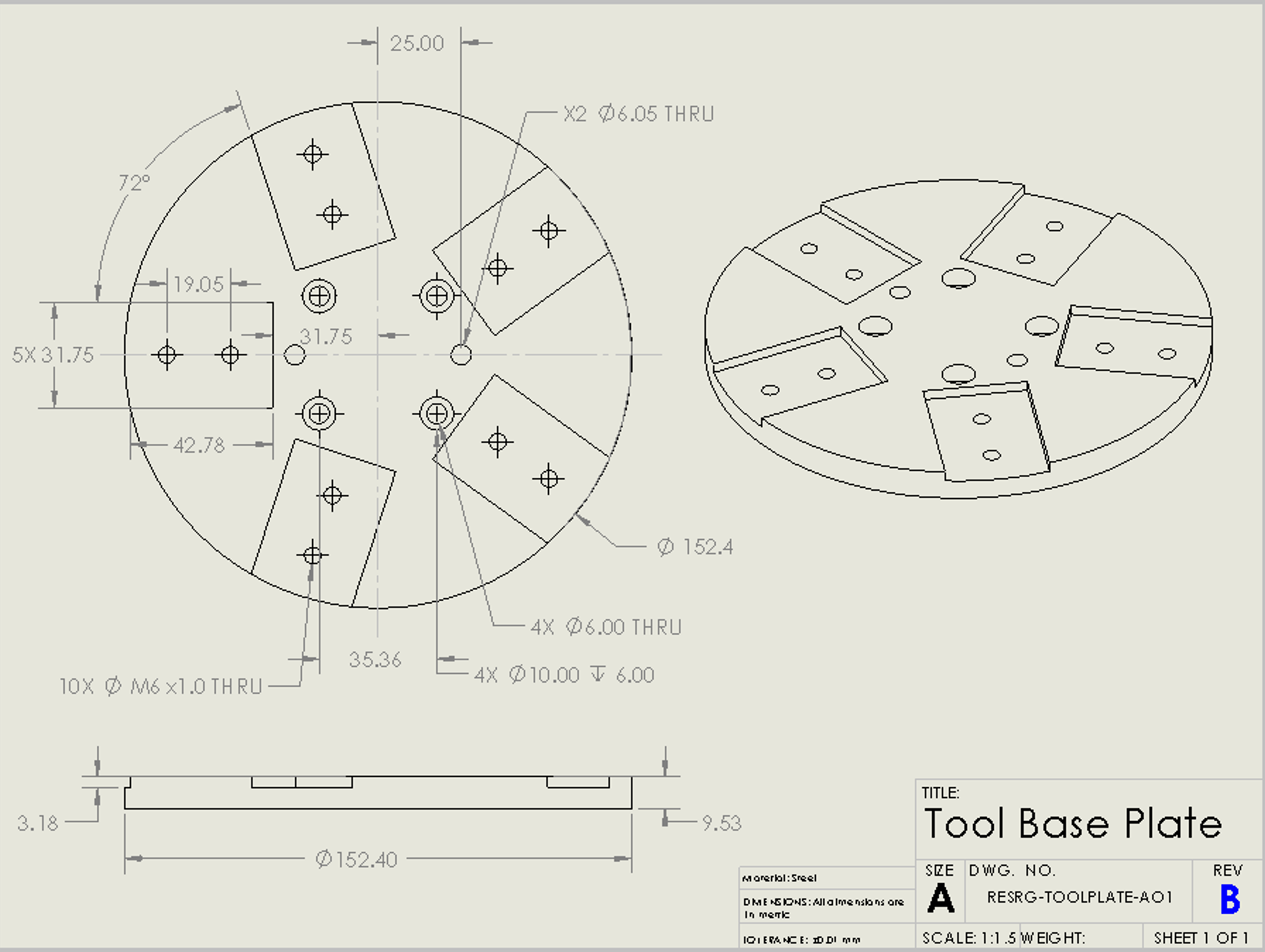

After confirming that the design was ready, I created working drawings to be machined.

Engineering Drawings for Machining

Machined Assembly

Once receiving the machined parts back, I had to grind down the insert pin that stabs the clip so that it was just the right fit. I did this using a Dremel with a grinder attachment taking off a little at a time.

Next, I assembled everything with loctite and put in all of the inserts.

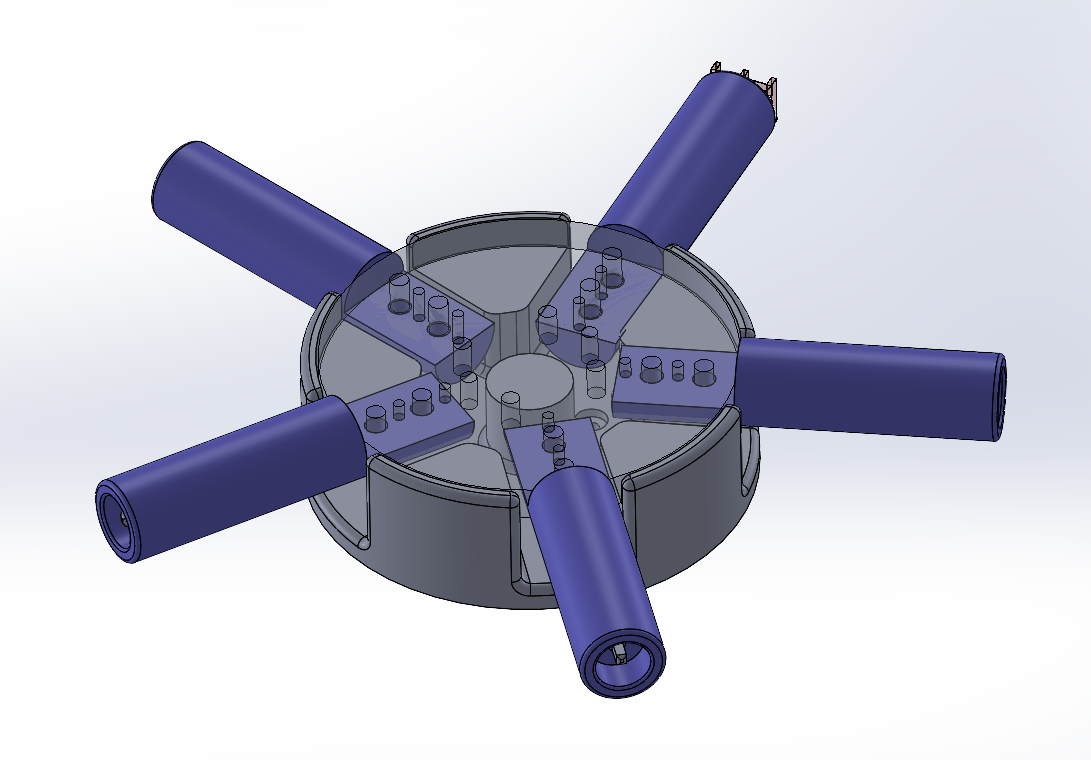

Tool Change Fixture Design

I am planning on creating a stand with extrusion to hold my fixtures, but the fixtures themselves are made to nest well with the EOAT out of TPU.

After printing it, it came out great.

Now I can begin building the stand.