Problem Statement

Design a 4.5lb robot with a shuffler drive system and a horizontal spinning blade to disable other robots in head-on-head head combat robotics matches.

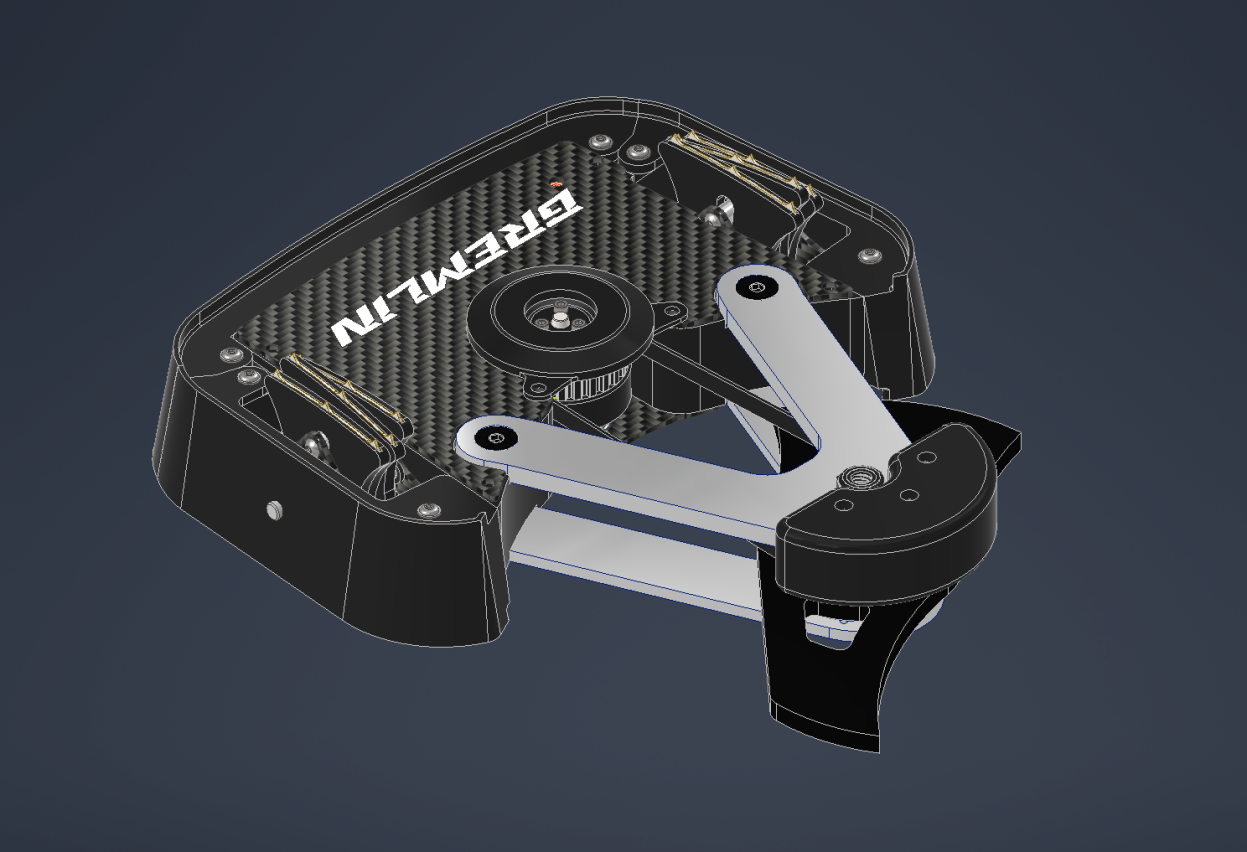

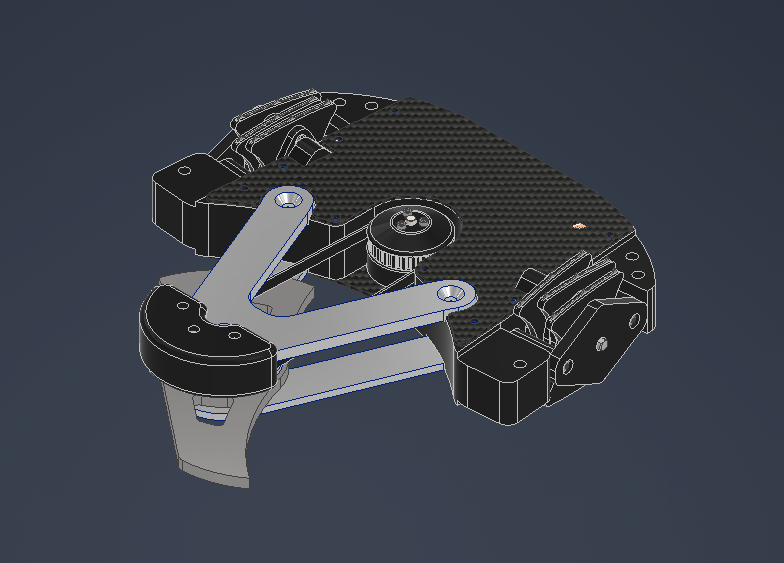

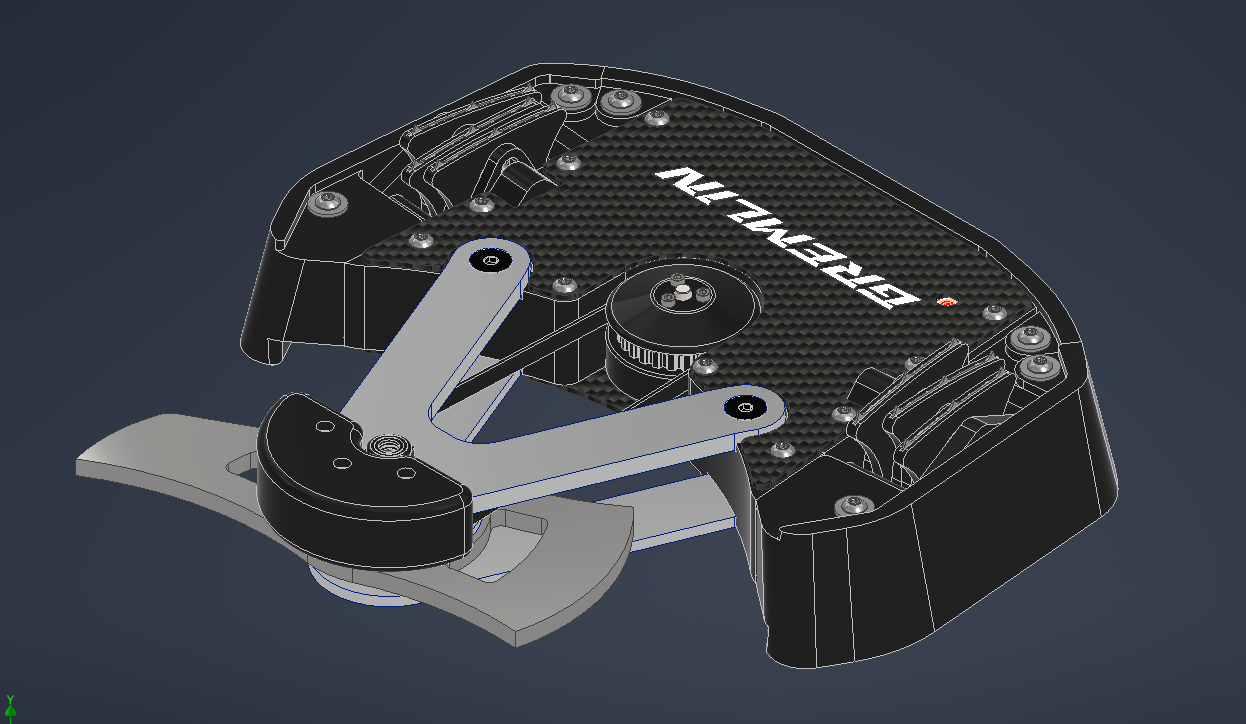

Shuffler Design

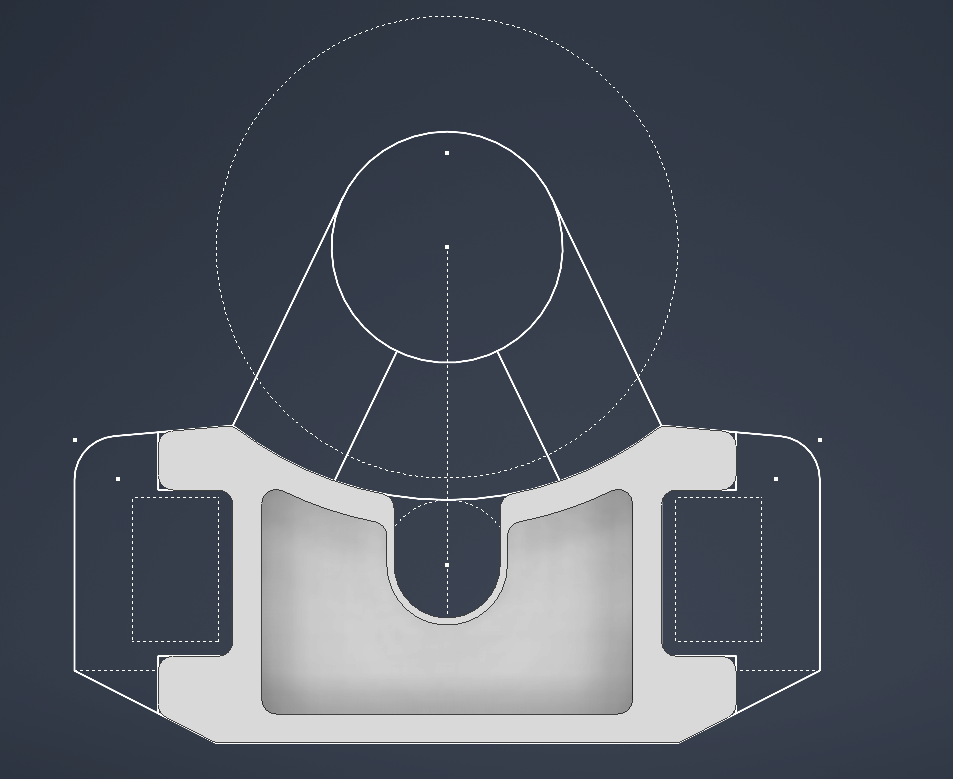

I started with the shuffler pods as they are the most complex part of the design. They utilize a camshaft with 3 different positions to create lateral movement.

For my drive motor, I want to direct drive the shufflers, based on the KV and my LiPo battery (4S 1100 Mah, 120c) I was able to choose a Blitz Pro High KV motor to get my desired RPM.

A demonstration of the movement is shown below:

Next, I printed prototypes:

After some evaluation, I realized my original plan to do 8 feet (4 facing up and 4 facing down) was going to be too heavy so I redesigned for 6 feet (3 facing up and 3 facing down)

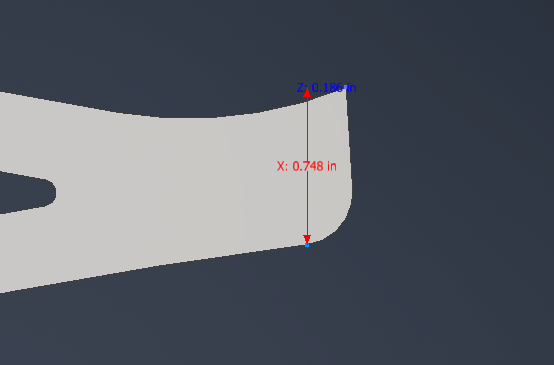

The big problem with this is that it was too big and I wanted to slim it down. As a result, I just decided to do 3 feet facing down with an asymmetrical shape up top.

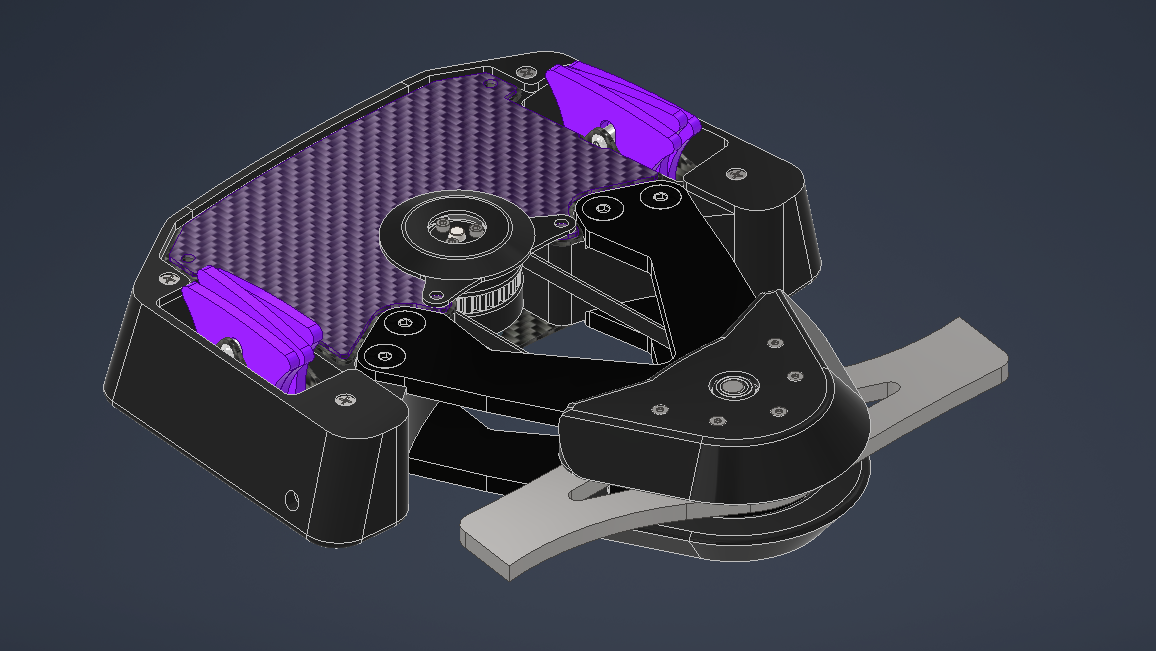

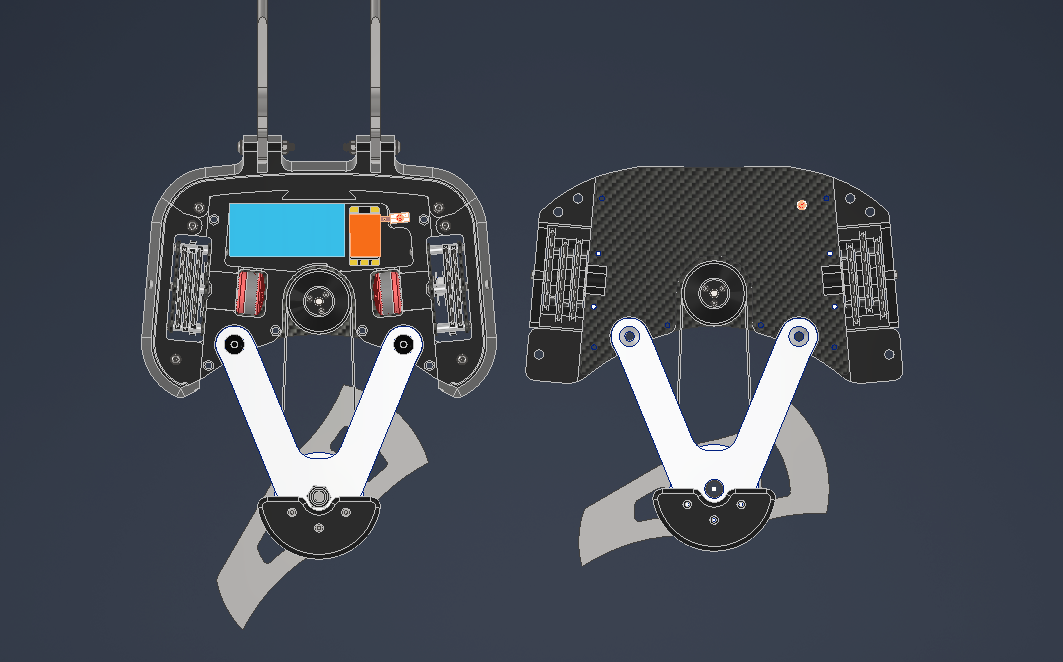

Body and Frame Design

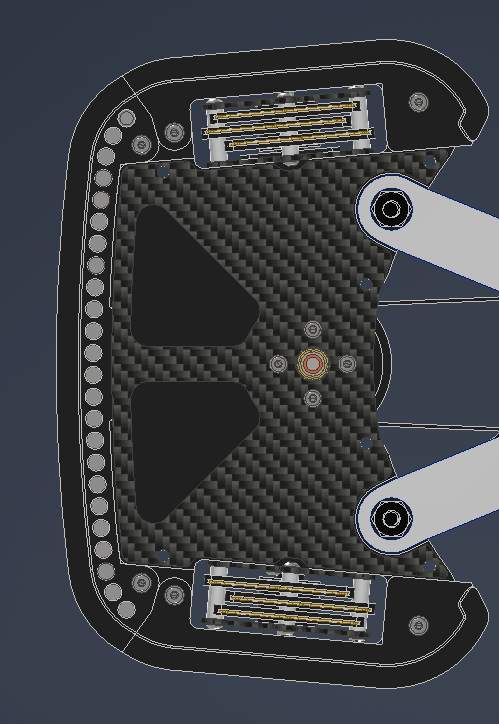

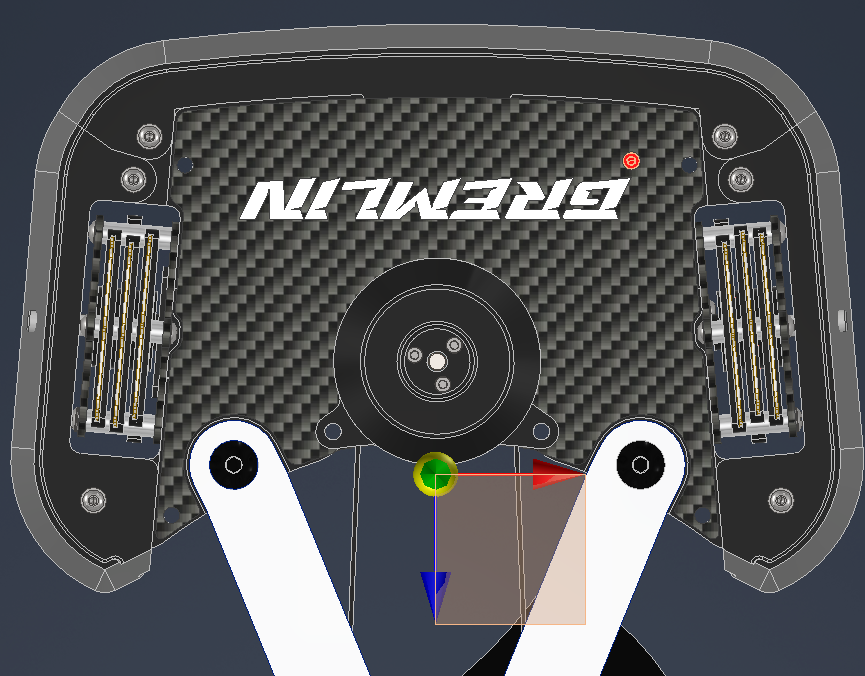

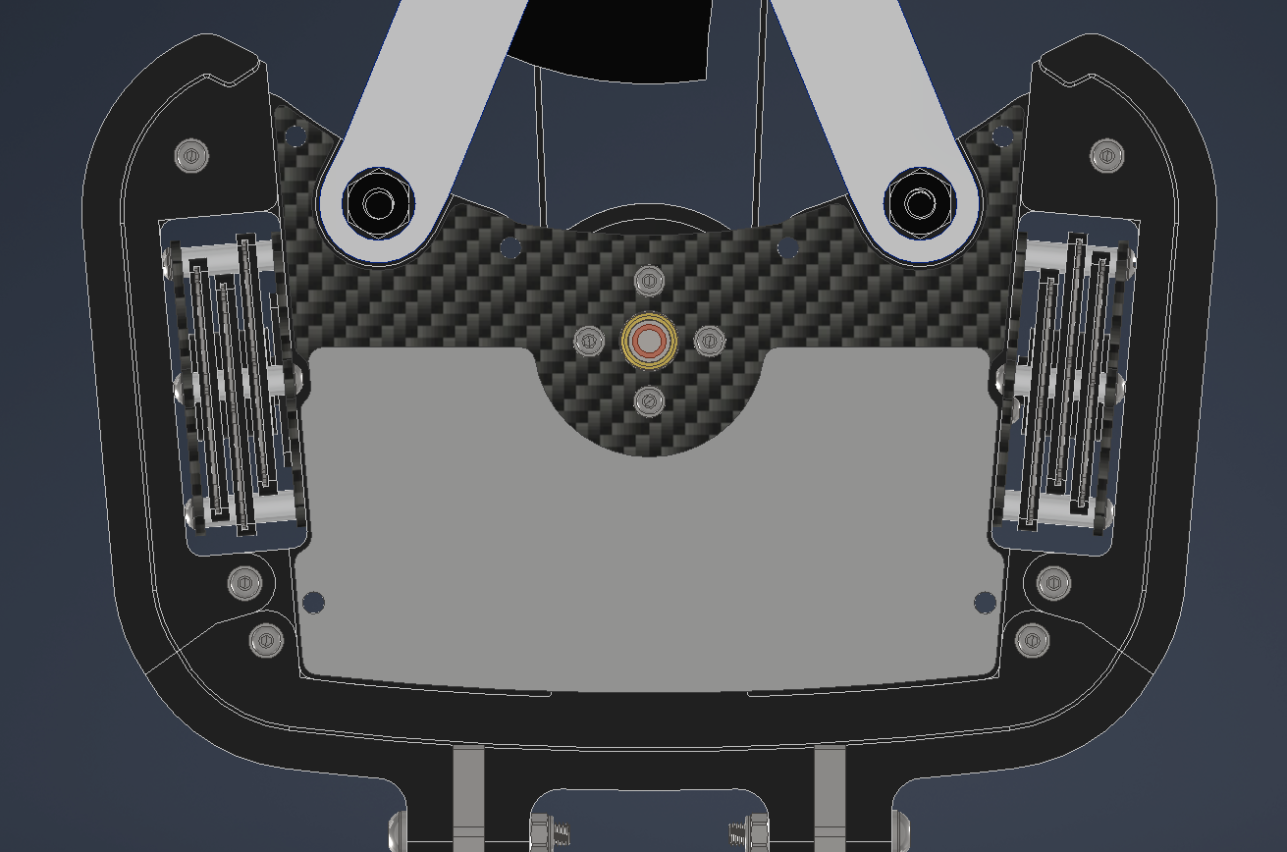

I started by master sketching the body so that it was easier to understand simpler geometry and where everything was going to go and fit.

.webp)

I am using TPU for the unibody with carbon fiber plates on the bottom and top to squish and strengthen it in that plane. For the weapon mount, I am using 1/4" aluminum. This is important because I need this to be the most rigid part of the robot.

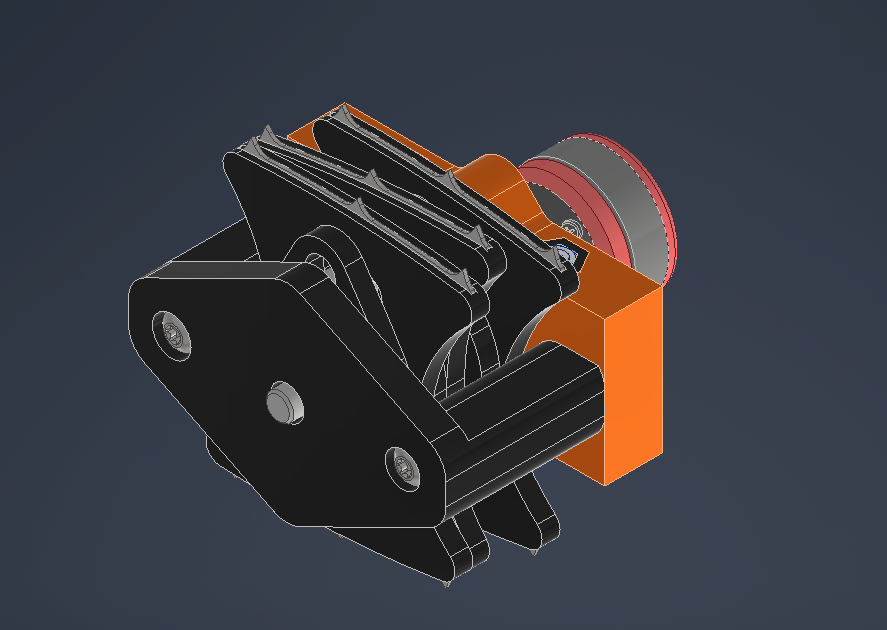

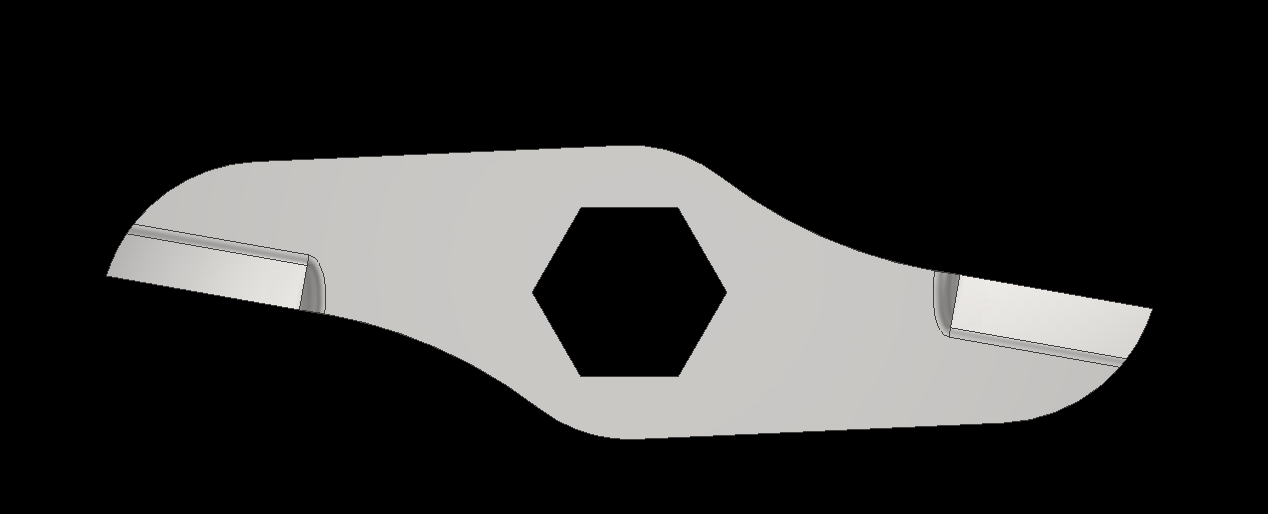

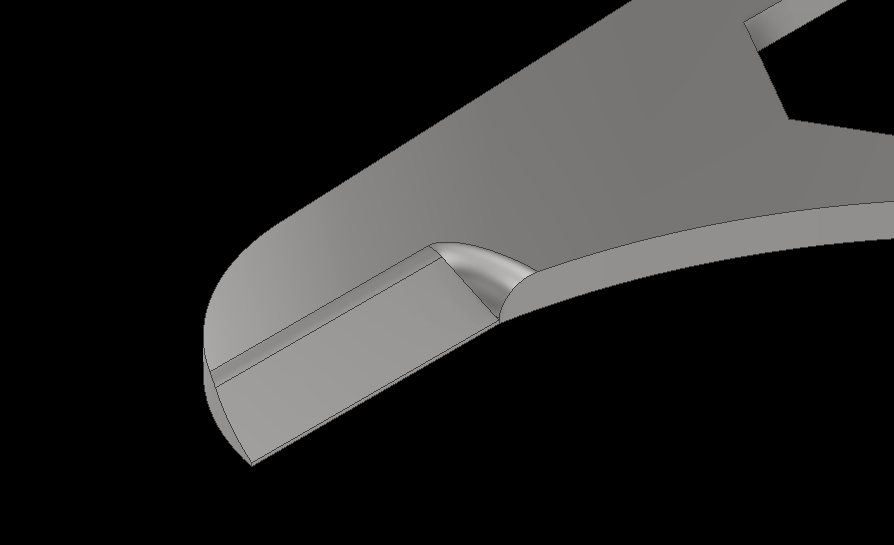

Weapon Design

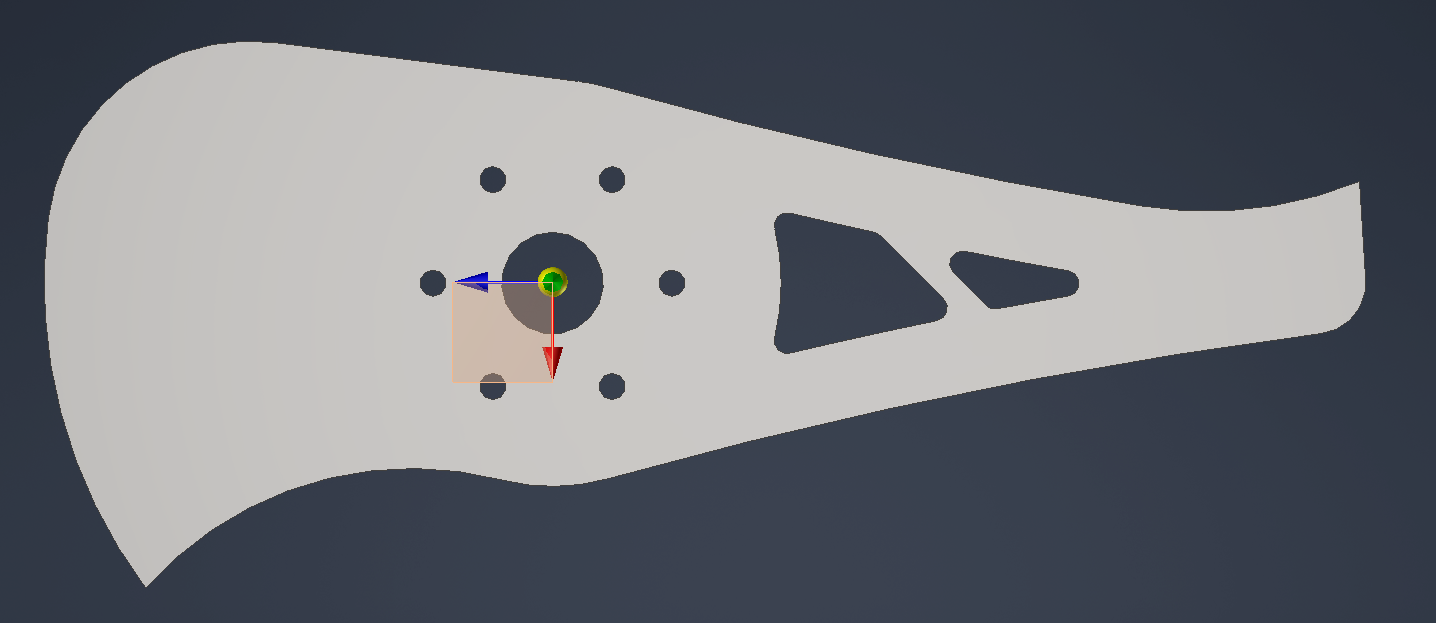

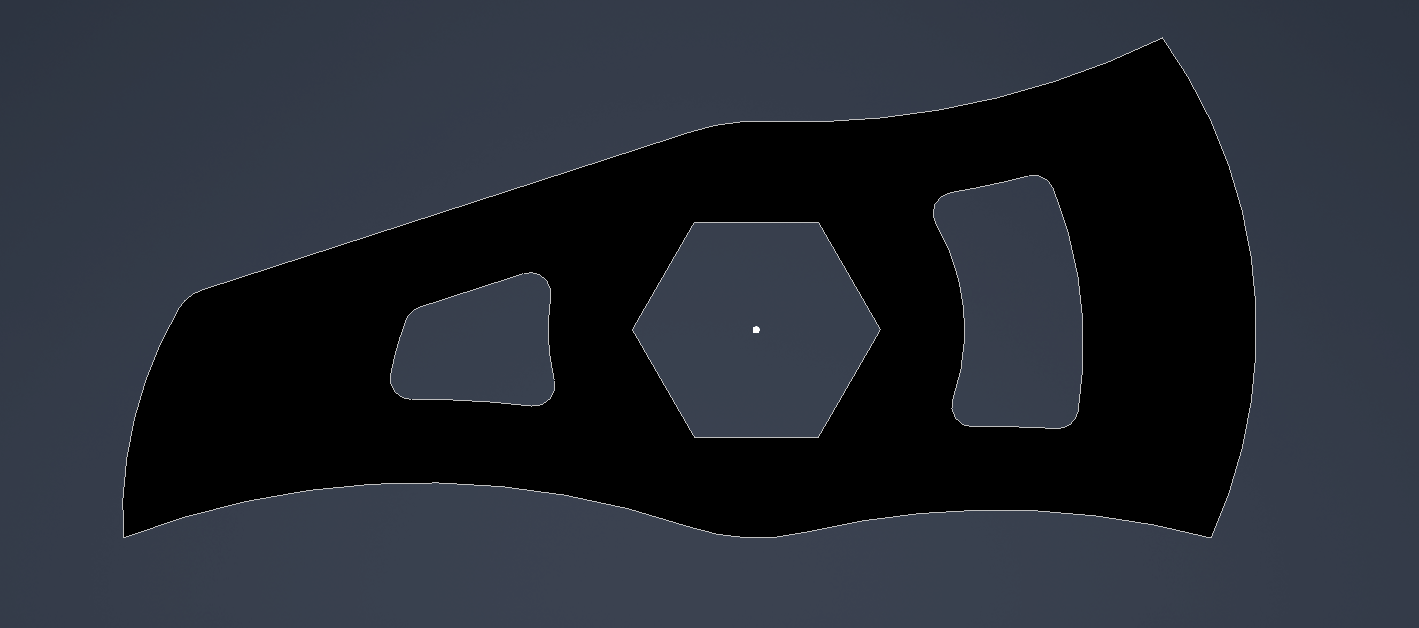

I then began designing my blade. My goal for the robot is to hit really hard so I need a lot of weight in the blade but also a thick tooth that will take impacts well. The blade is made out of AR600 steel which I will machine by water jetting the 2D shape.

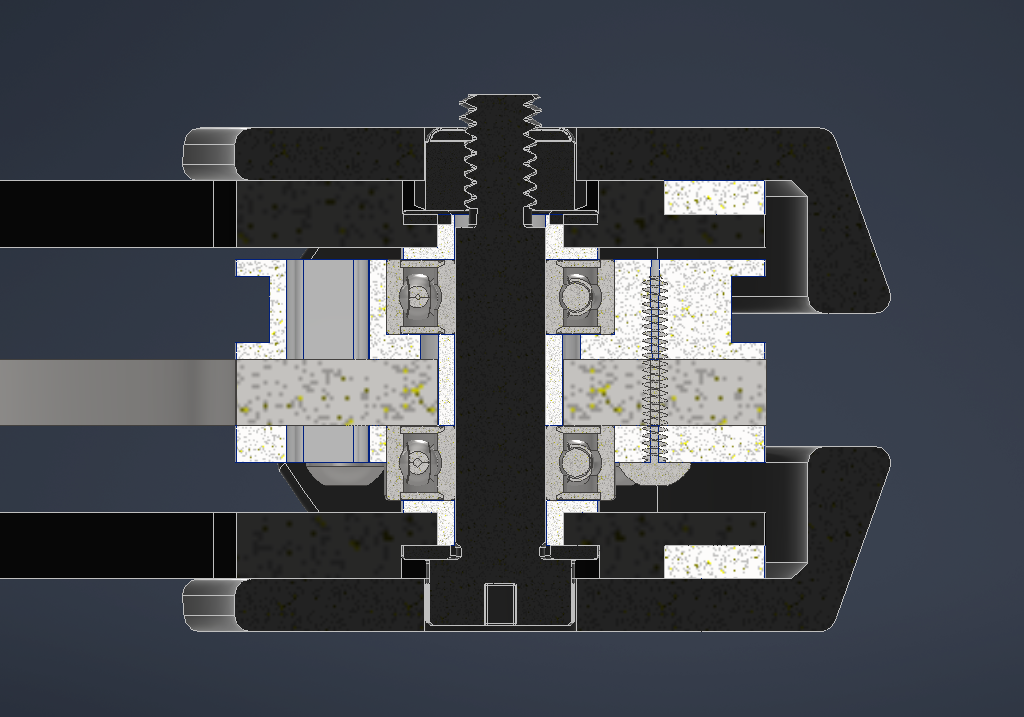

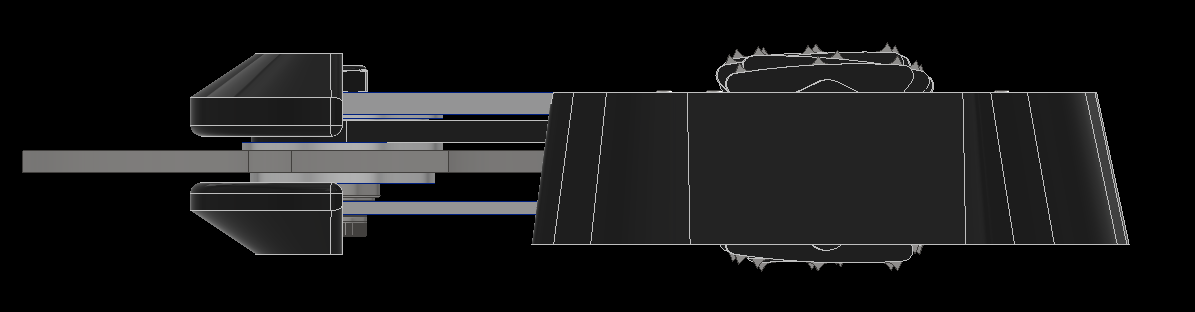

For the weapon stack, I need to make sure there is not a lot of flex. I am using 2 bearings on either side of the blade with aluminum parts that they integrate into. There is a 3/4" dead shaft running all the way through for the blade to spin around. The pulley is smooth for the timing belt to go around and power the weapon. Finally, there are bushings on each side to keep the bearing from contacting the aluminum frame.

The biggest problem with this design is that the screws are under sheer. I am going to design a new pulley and blade with a keying feature for rotational torque transfer instead.

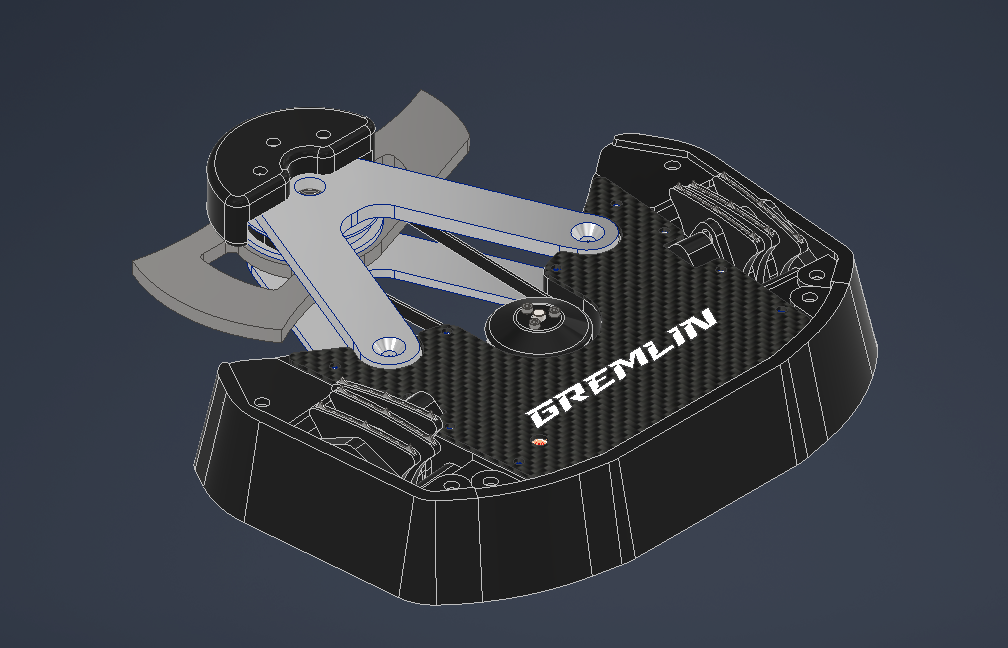

Armor and Final Additions

I then added TPU armor around the shufflers, the back, and the weapon. I also decided to thicken the weapon frame to remove flexibility.

Additionally, I created a cover for the weapon motor and added the toothed sleeve to power the weapon.

I dislike the mounting of this armor however, so I am going to shift to screwing only from the top with a standoff going thru the whole armor part. I also dislike the look of the nose protecting the weapon, so I am going to redesign that as well.

I also discovered the weapon frame was a little heavy, so I reduced weight there.

Assembly

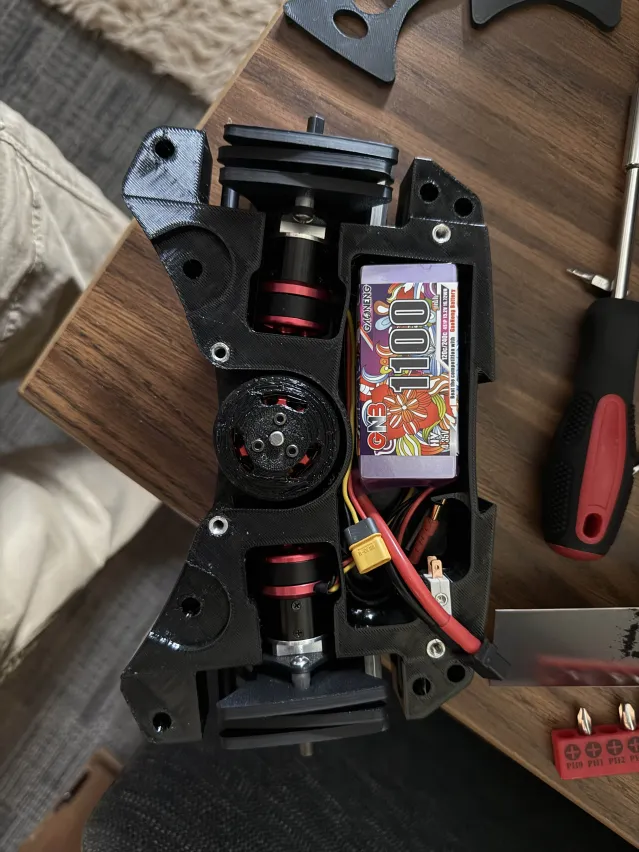

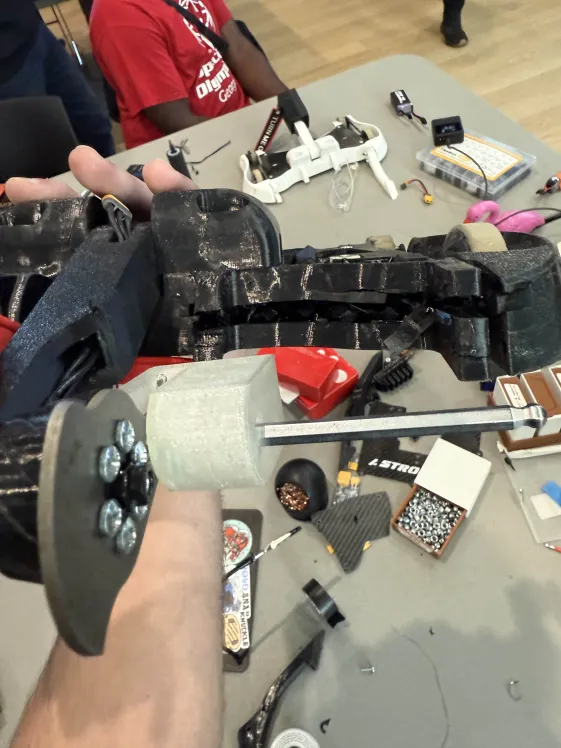

Assembly began with initial prototypes to make sure everything fits together properly.

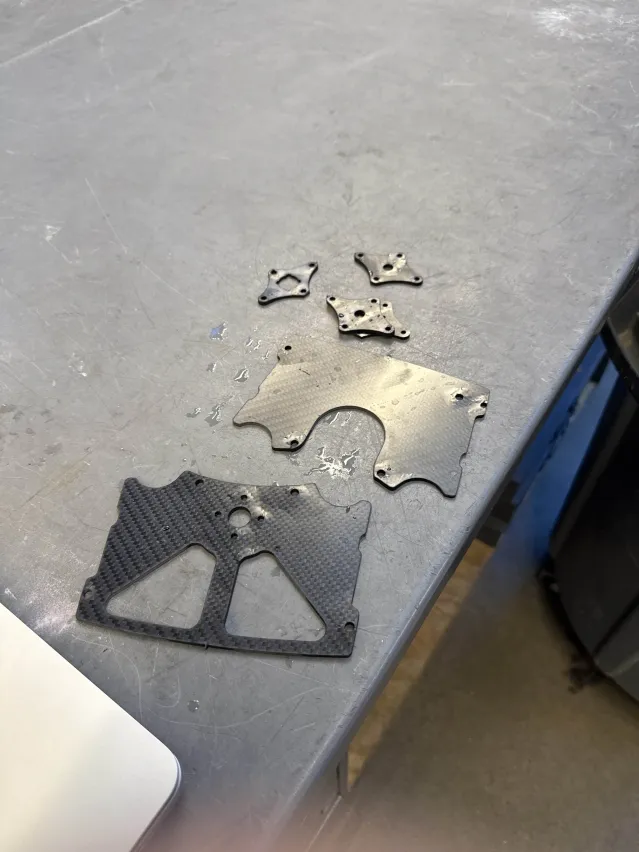

I then water jetted my carbon fiber parts for the shufflers and the top and bottom plate. I also printed the armor.

After making one minor change to the unibody, I reprinted it and started working on mounting the shufflers. I also removed the printed weapon assembly so I could start making the real one. I also started planning the electronics layout so I could begin soldering everything.

Next, I was able to do a drive test with the PLA shufflers I have.

The robot drives phenomenal, meaning I can move on to getting the weapon assembled and creating the actual shufflers.

To make the shufflers I am pause printing in spring steel cleats since the arena is made out of wood. This will give me traction in the ground.

All of the tests went well, and I feel prepared for the Georgia Tech tournament on 10/25/25. The robot ended up being almost a pound underweight which is something I plan on fixing for the future tournaments.

Fall Jacket Racket - 10/25/25 Results

I went 1-1 at the tournament before having to forfeit a match due to my weapon motor burning up. My takeaways are as follows:

- The motor cover having air flow holes is not necessary and it meant shards of conductive material could get into the coils and burn the motor

- Top armor is necessary for going against overhead attack robots

- I need spare motors

- The blade slows down too much after a hit

My next tournament is the UGA Spooky Smash tournament on 11/08/25 so I have a good amount of time to make some improvements to the robot.

UGA Spooky Smash Robot Improvements

The first thing I did was use my extra weight to add dowel pins to the back of the robot. This helped me get my center of gravity way closer to the point of rotation and will improve my drive movement significantly. It also strengthens the back armor.

Next, I designed a new blade with a more dramatic sweeping curve, so it sweeps through material better after the initial cut. It also has a really thick tooth to avoid being bent by vertical spinners and to add some weight to the weapon. I opted to switch from my previous symmetrical blade design so I can conserve more energy in between hits.

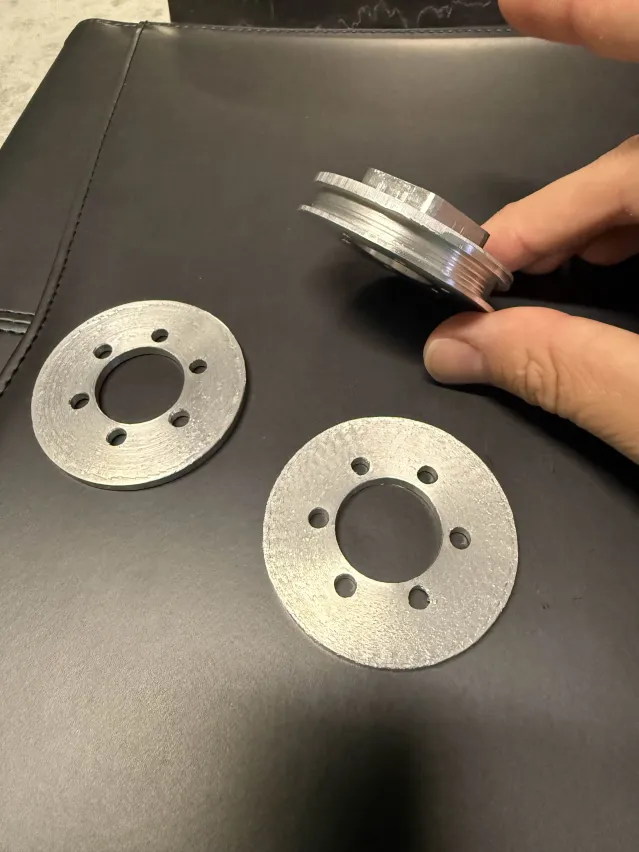

I also upgraded my glass fiber nylon pulley to an aluminum pulley for even more rigidity in the weapon stack.

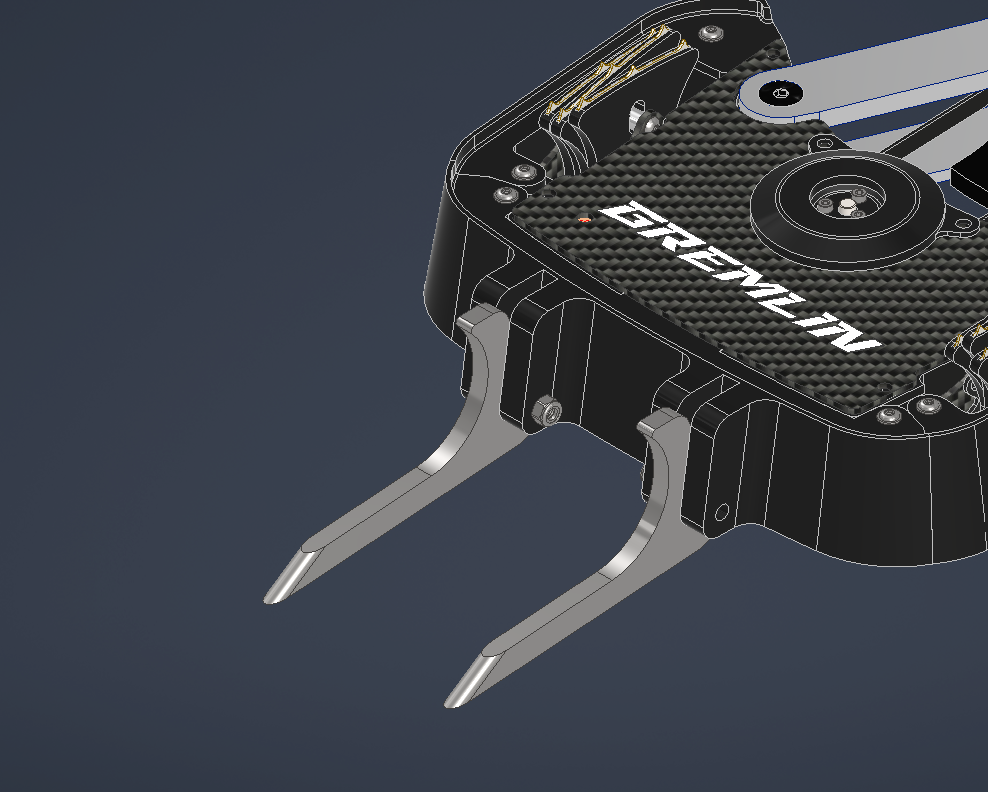

Next, I designed a fork configuration that will allow me to play control in case my weapon does go down like at Georgia Tech. (In combat, you get points for having control, aggression, and dealing damage).

I then created titanium top and bottom armor to protect from overhead attacking robots.

Now I was able to start machining all of the new upgrades.

UGA Spooky Smash - 11/08/25 Results

I placed 2nd at the UGA Spooky Smash competition! Robot stats included:

- 5-2

- 5 KOs

- 2 losses were to the same robot (vertical spinner - Kintsurugi who got 1st)

Some notes from this competition include:

- Repairing the shufflers is too slow

- Pulley flanges were too small - belt kept slipping off

- Current blade hits really hard and weapon stack is very rigid

- Shufflers drive well but need 3 facing up and 3 facing down for better upside-down driving

- Armor shreds too easily

My next competition is the National Havoc Robotics League (NHRL) event in Connecticut 02/07/26. This is a very competitive competition, but it means I have lots of time. Because of this, I am going to go for a full redesign to fix these issues.

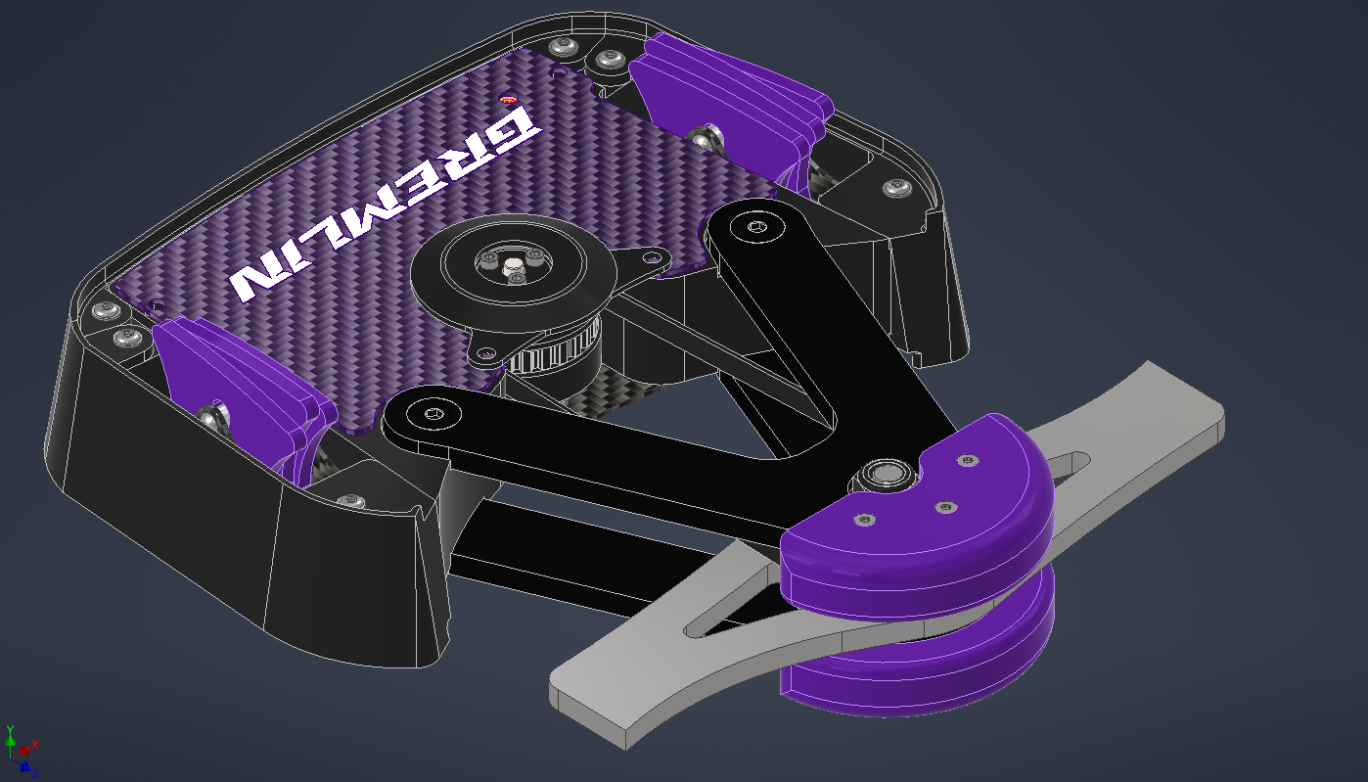

New Redesign for 02/07/26 NHRL Event - Version 2

Some design criteria I have include:

- Use same weapon frames (I currently have 6 right now so I already have lots of spares)

- Use same weapon (It worked very well at UGA)

- Maintain same electronics (again already have spares and is cheaper)

- Create drop in shuffler pods for easier repairs

- Open up space inside a little bit for less tight electronics and drive motor connectors so they can be swapped without resoldering

- Higher infill armor

- Larger, better designed pulley

I started with the shufflers and the body.

Then I worked on creating the new armor. I also sloped the nose so that it didn't scrub the ground so much.

Because the shufflers are heavier, when I run my titanium top and bottom armor, I am overweight. To fix this, I am using a thinner blade that is specifically to cut through TPU easily, which helps a lot when fighting top attack robots.

The robot got a little bigger, but I feel like it will hold up better through a fight and be easier to maintain and repair. I am now ready to begin assembly and get ready for the tournament.