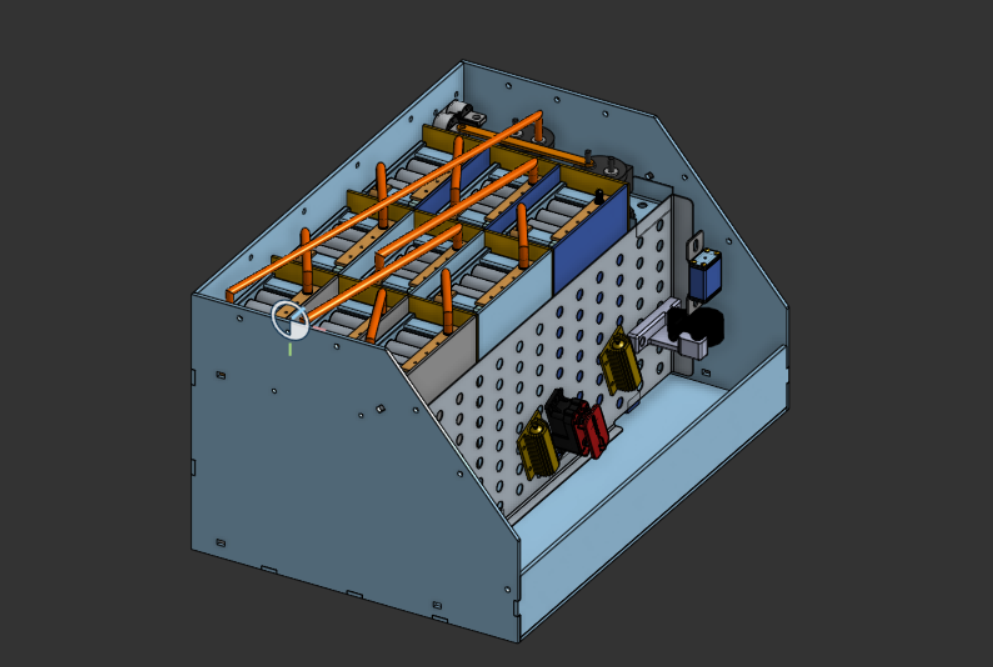

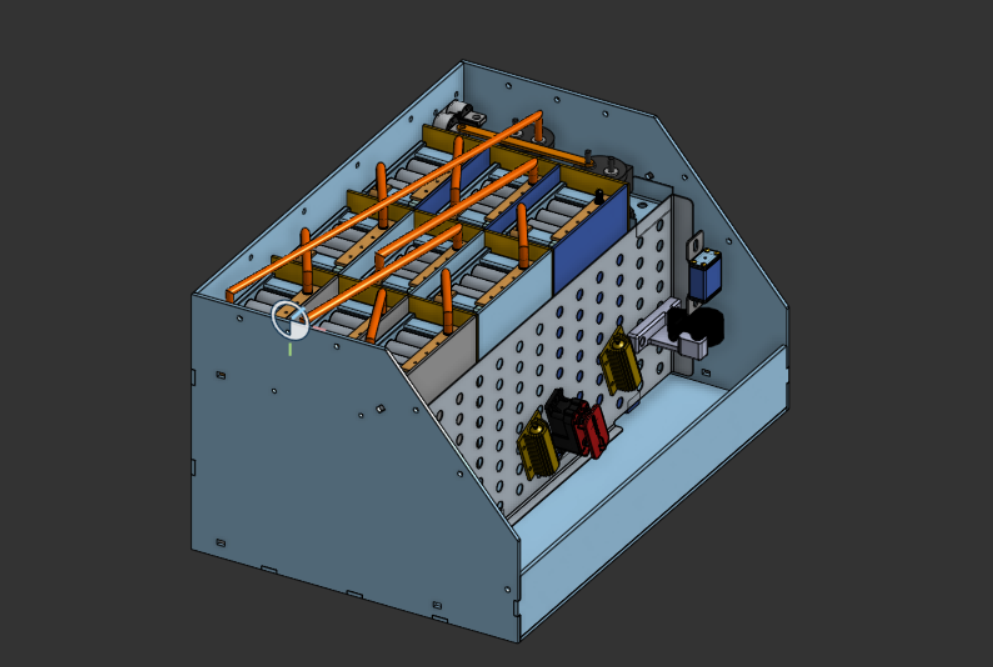

Near-complete mock-up CAD model on Onshape software

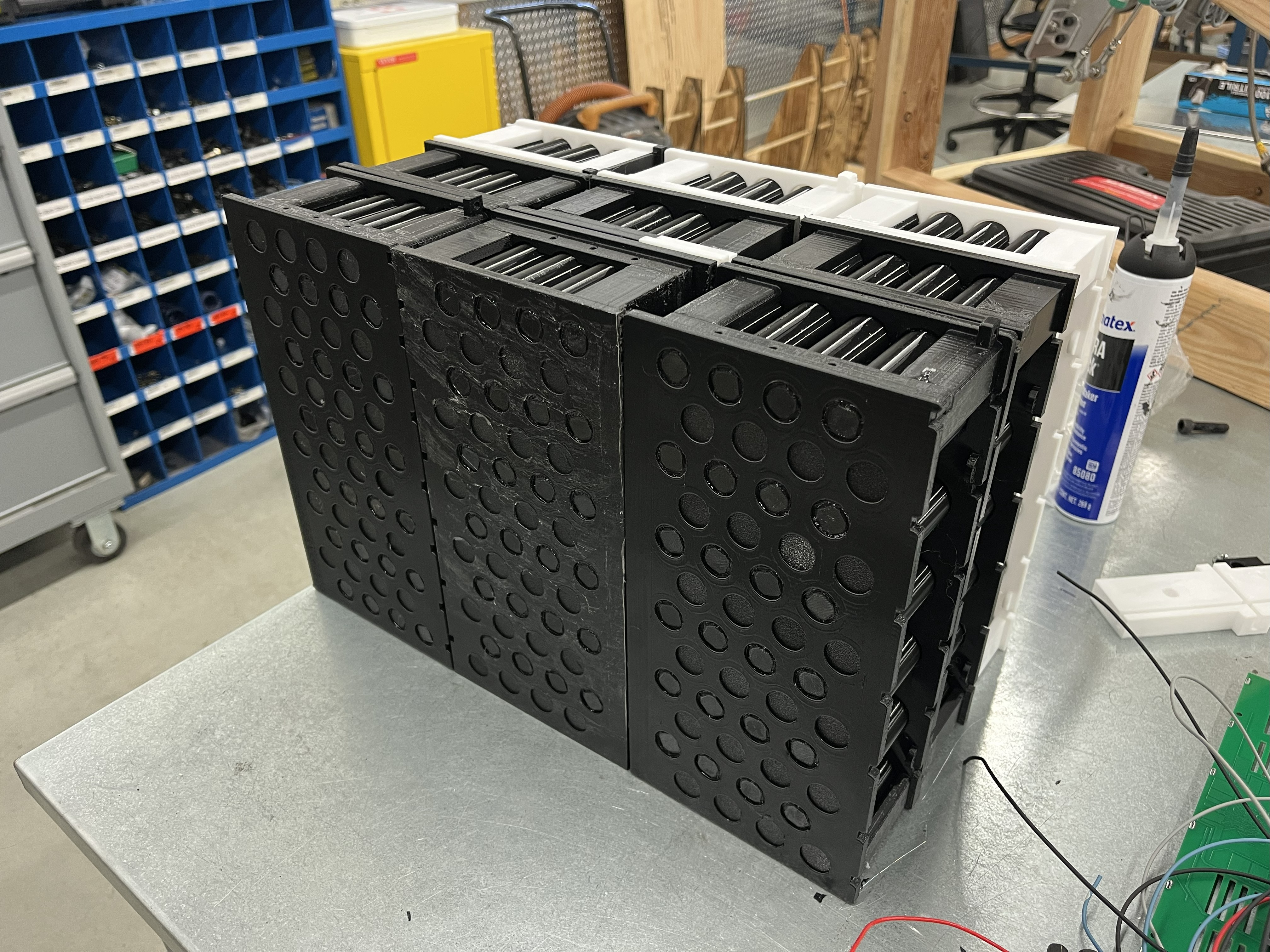

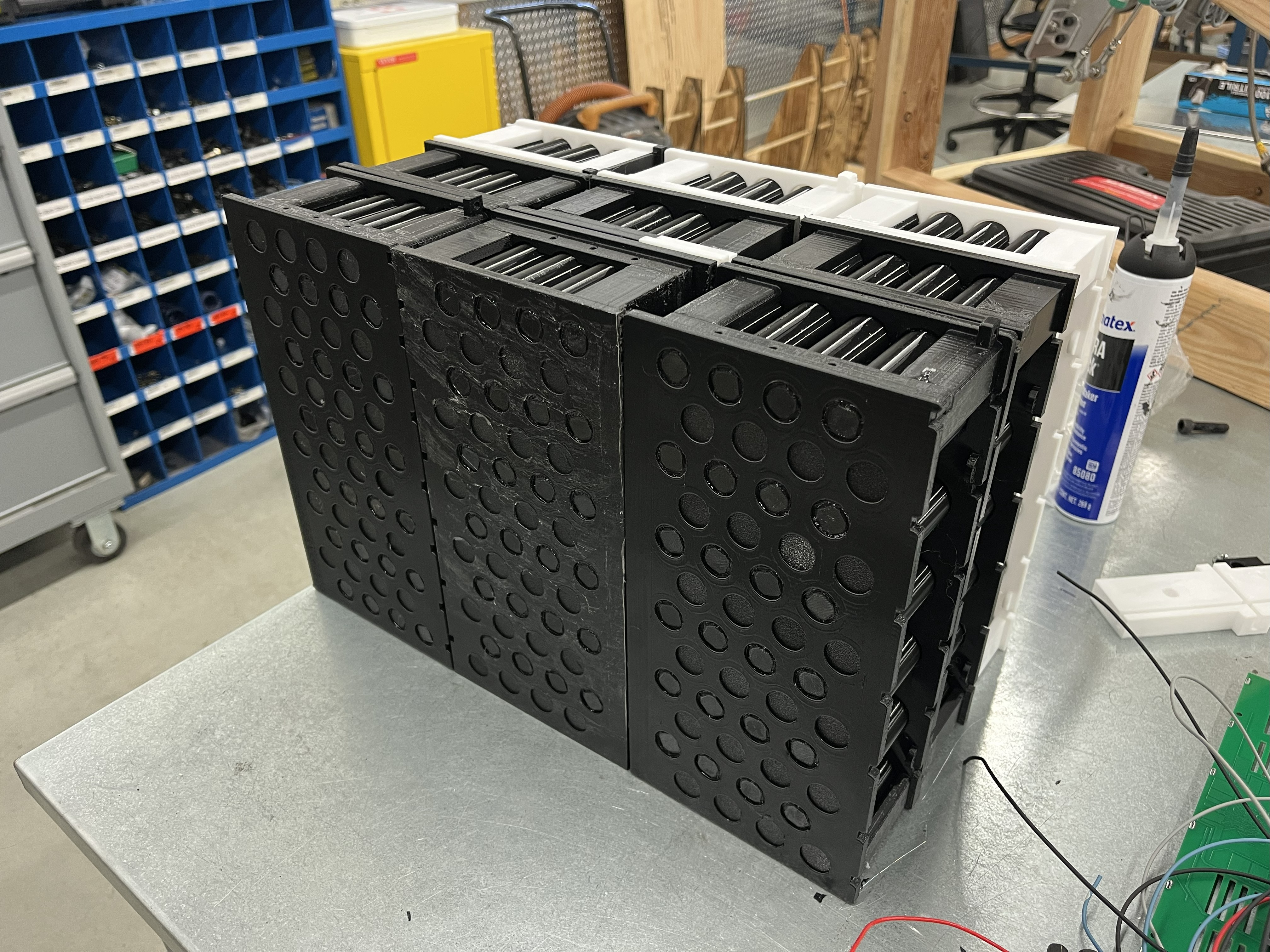

Chasis of the E-Formula car & 3D printed physical mock-up of battery modules

Sep 2025 - Current

▪ Led complete mechanical design and FEA validation of the accumulator’s module attachment structures (rails, internal walls, insulation interfaces), ensuring structural integrity and compliance with FSAE EV rules.

▪ Designed an 18-piece rail system in Onshape that forms a rigid, removable assembly to restrain all battery modules while simplifying manufacturing and installation.

▪ Performed multiple FEA simulations (static load, buckling, and safety-factor verification) to confirm structural performance and reduce system weight while maintaining required margins.

▪ Engineered fit-check and form-and-fit mockups of module components using 3D printing to validate internal packaging, fastening, and installation sequence before manufacturing.

▪ Optimized electrical component layout inside the accumulator box to improve thermal performance, reduce wiring complexity, and enhance assembly efficiency.

▪ Coordinated mechanical–electrical integration with HV and LV teams, ensuring proper spacing, insulation clearance, and compliance with rules such as F.10.2 (insulation) and F.10.3 (mechanical loading).

▪ Developed manufacturing drawings and BOM for rails, walls, and support hardware to support fabrication and welding of the final accumulator enclosure.

▪ Streamlined assembly workflow by designing module restraints that improve serviceability and reduce installation time for the electrical team.

▪ Conducted rule verification analysis for internal walls and insulation layer equivalency to meet FSAE requirements for steel/aluminum substitutive materials.

▪ Delivered design review presentations (SDR, CDR, subsystem reviews) demonstrating CAD models, FEA results, and decision-making processes to faculty advisors and team leadership.

Near-complete mock-up CAD model on Onshape software

Chasis of the E-Formula car & 3D printed physical mock-up of battery modules