Kineto Tracking Mount (KTM)

A Kineto Tracking Mount (KTM) is a mechanical tracking system designed to follow fast-moving aircraft or missiles so their motion can be filmed, measured, or analyzed. It’s commonly used in flight testing, weapons testing, and research ranges.

At YPG, my project was to redesign the outdated manual calibration scope, which had no zoom capability, into a fully digital calibration system using a high-resolution camera and an optical lens capable of up to 100× magnification. This design implementation completely removed the need for physical interation on the KTM when calibrating in between tests.

This project was necessary because, for decades, KTM operators had to sit directly inside the nesting of the tracking mount and manually operate it while it was moving. In recent years, the control system was upgraded to a fully digital interface, eliminating the need for an operator to physically ride on the KTM and allowing them to control it remotely from a computer inside a building at a safe distance. My project was the final step needed to make the entire KTM calibration process fully digital thus removing the last requirement for operators to climb onto the KTM and look through an outdated, inaccurate manual “scope” to perform calibration

Presentation

At the end of my internship at YPG, I had the opportunity to present my work and results to senior-level engineers across related disciplines. They were thoroughly impressed with the progress I achieved in just 10 weeks and noted how consistently and diligently I worked throughout the project. Following the conclusion of my internship with ASRC Federal, I was informed that I had outperformed all 47 interns at various test sites across the country and would be receiving a $500 award and a formal letter of recognition for having the “Best Intern Project and Presentation.”

Project Progress

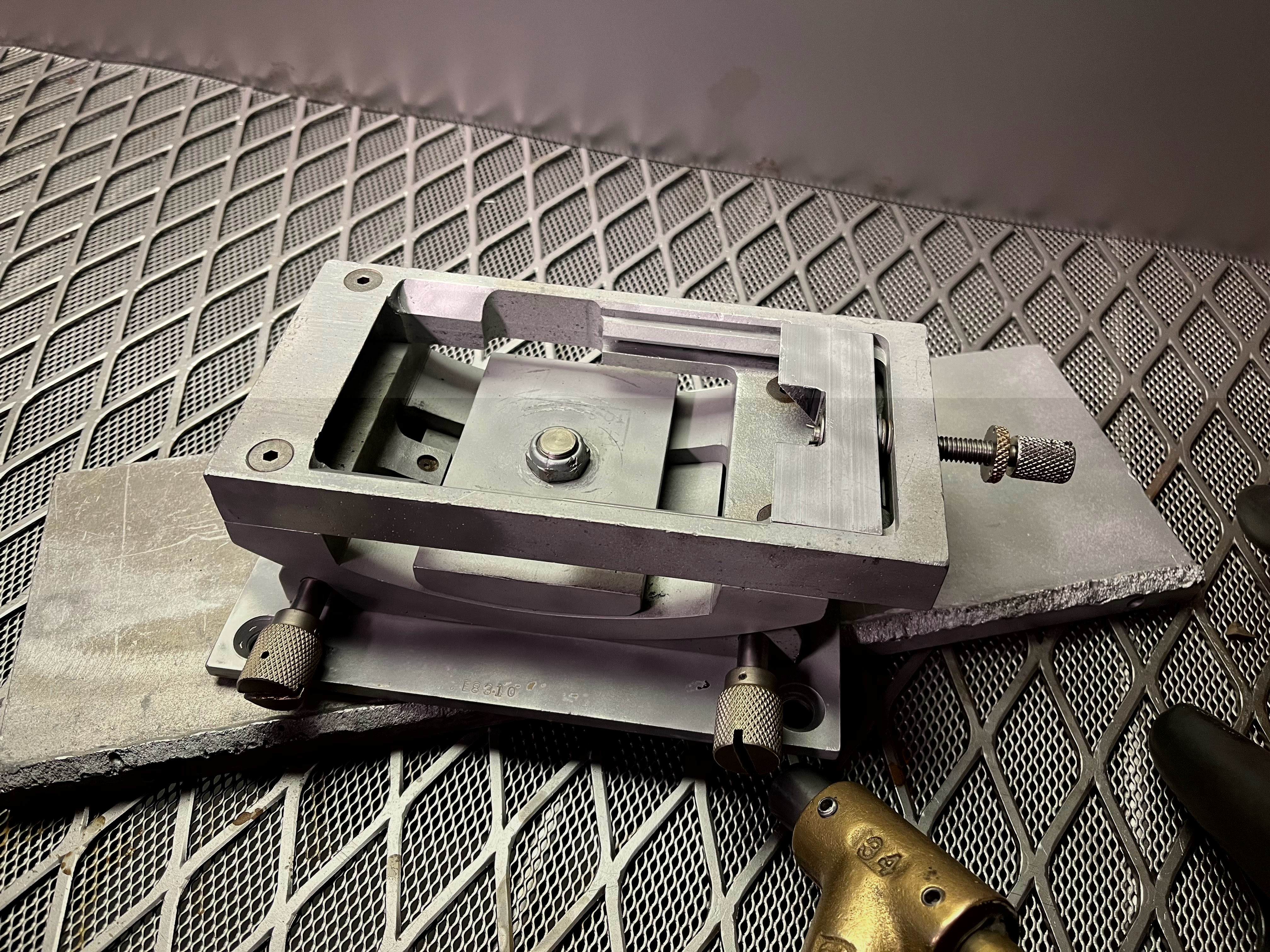

Before reaching the final project outcome, I was responsible for all prototyping using 3D printers and manual mills, as well as the complete design development and testing process.

Yuma Proving Groungs (YPG) on-site testing

I was also able to help on various tests on-site, including the tests of an M1 Abrahams tank, signal testing at a desired wavelength from an airplane, and had the chance to ride in a Blackhawk helicopter over YPG.