Carbon Fiber and Kevlar Vacuum Infusion

Composite Manufacturing and Production Processes Project

Project overview

This project focused on the manufacture of structural composite components for Pilates reformers using vacuum infusion molding with carbon fiber and Kevlar reinforcements. The objective was to produce lightweight, durable parts with consistent quality while developing hands-on experience in production-oriented composite manufacturing. Emphasis was placed on process control, repeatability, and material handling rather than one-off prototyping.

Material selection and reinforcement strategy

Carbon fiber and Kevlar were selected to balance stiffness, strength, impact resistance, and weight. Carbon fiber was used where rigidity and structural performance were critical, while Kevlar was incorporated for improved toughness and damage resistance. Reinforcement choices were driven by functional requirements of the reformer components and durability under repeated loading. Reformers were produced in both strict carbon fiber, and carbon-kevlar hybrid weave configurations.

Mold preparation

Molds were prepared to ensure clean surface finish and reliable part release. This included cleaning, applying release agents, and verifying mold integrity prior to layup. Proper mold preparation was essential for achieving consistent surface quality and minimizing post-processing work across multiple parts.

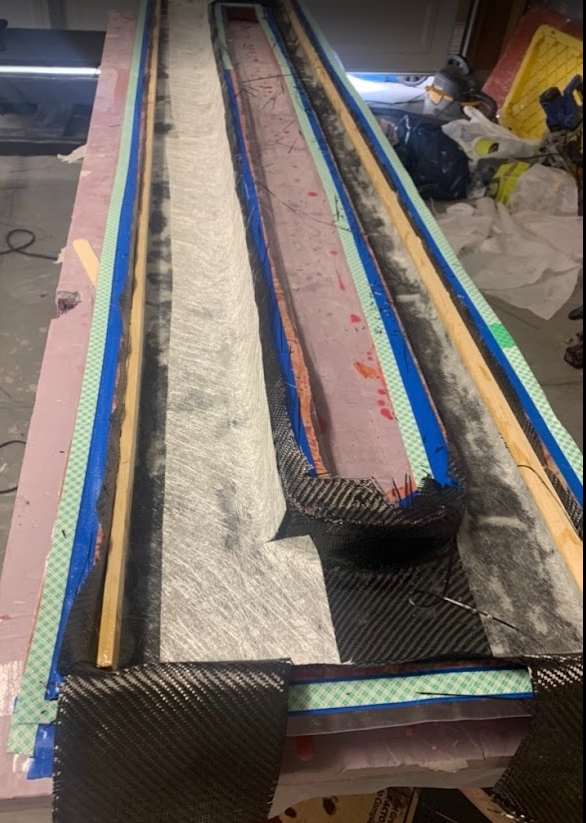

Fiber layup and pre-infusion setup

Dry fiber layups were carefully staged in the mold, with attention to ply orientation, coverage, and overlap in higher-load regions. Peel ply, flow media, and resin distribution paths were added to promote even resin flow during infusion. This stage required careful planning to avoid dry spots and ensure complete wet-out across complex geometries.

Vacuum bagging and leak checking

The layup was sealed using vacuum bagging materials and fittings, followed by leak checks to verify vacuum integrity. Achieving and maintaining a stable vacuum level was critical to resin flow consistency and final laminate quality. Any leaks were identified and corrected before infusion to prevent voids or incomplete saturation.

Resin infusion and wet-out monitoring

Resin was introduced under vacuum and allowed to flow through the fiber stack until full wet-out was achieved. Flow progression was monitored to ensure even distribution across the part, adjusting clamp timing as needed to control resin front behavior. This step emphasized timing, attention, and understanding of how resin viscosity and fiber architecture affect flow.

Cure and demolding

After infusion, parts were allowed to cure under controlled conditions to achieve full resin polymerization. Once cured, components were demolded and inspected for surface quality, fiber wet-out, and structural consistency. Proper cure control contributed to repeatable mechanical performance and dimensional stability.

Inspection and finishing

Finished parts were trimmed, cleaned, and inspected for defects such as voids, resin-rich areas, or incomplete saturation. Edges and interfaces were refined as needed to meet fit and finish requirements for integration into the reformer assemblies. Inspection focused on consistency across parts rather than cosmetic perfection alone.

Production mindset and outcomes

This project reinforced a production-focused approach to composite manufacturing, where repeatability, cleanliness, and process discipline directly influence part quality. Working with both carbon fiber and Kevlar expanded material familiarity and highlighted how reinforcement choice affects handling, infusion behavior, and final performance. The resulting components met structural and durability requirements for real-world use in Pilates reformers.

The reformer is lifted overhead, demonstrating its lightweight construction.