Airfoil Modeling and Experimental Testing

CAD-Driven Aerodynamics and Physical Validation Project

Project overview

This project explored the relationship between airfoil geometry and aerodynamic performance through a combination of CAD modeling, rapid prototyping, and experimental testing. Multiple airfoil shapes were modeled in Fusion 360, fabricated via 3D printing, and tested in a makeshift wind tunnel to evaluate lift generation and pressure behavior. The goal was to connect theoretical aerodynamic concepts with hands-on measurement and data analysis.

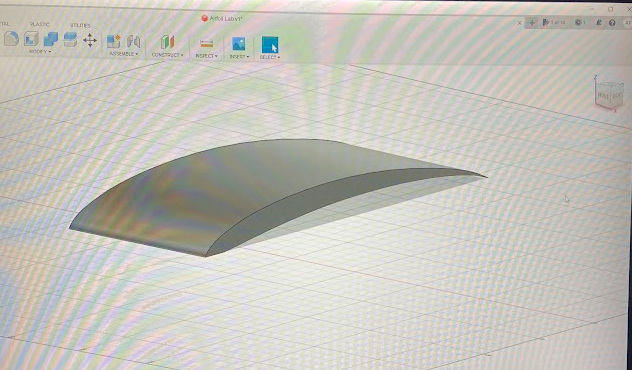

Airfoil design and CAD modeling

Airfoil geometries were created and modified in Fusion 360 to study how changes in shape affected performance. CAD models were developed with consistent reference dimensions to allow fair comparisons between profiles. This approach enabled controlled variation of geometry while maintaining repeatability across test samples.

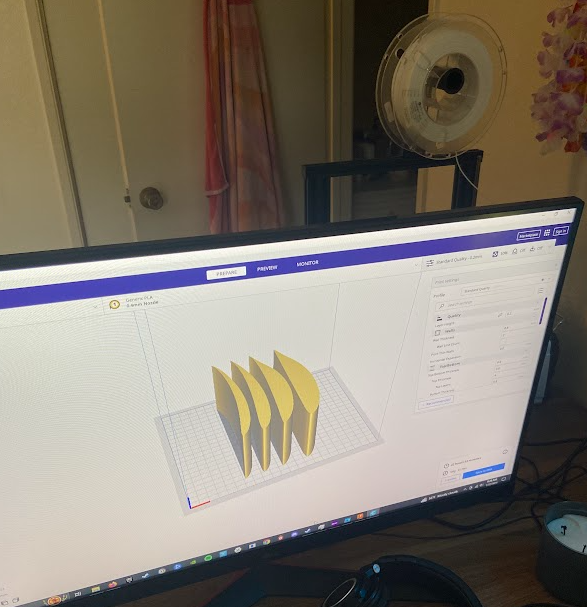

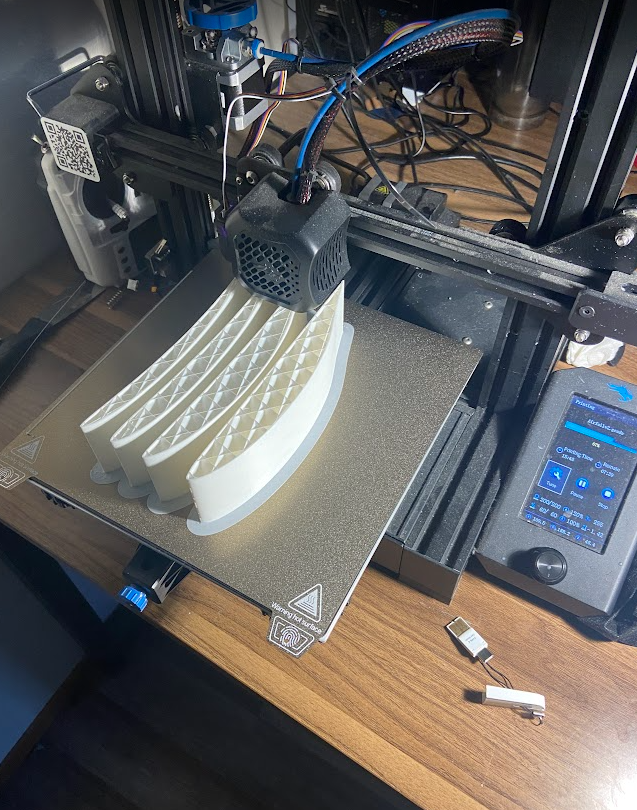

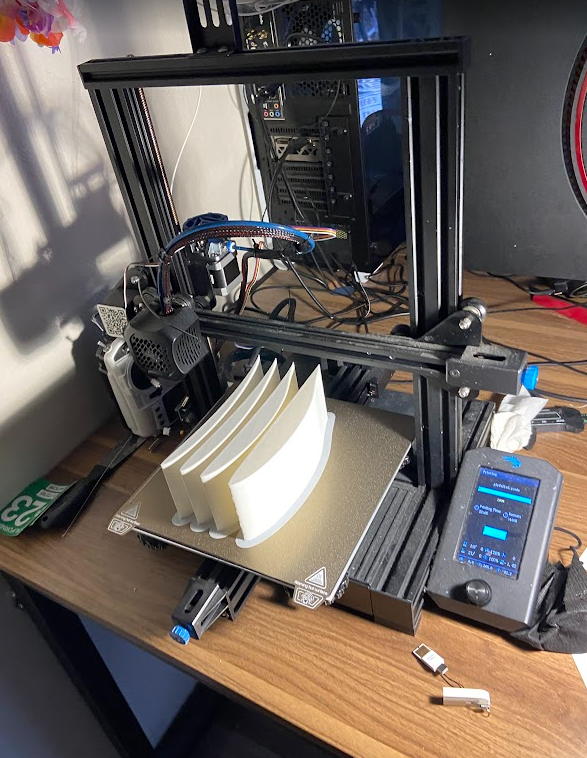

Prototype fabrication

Each airfoil was fabricated using 3D printing to allow rapid iteration and consistent reproduction of geometry. The printed airfoils were post-processed as needed to ensure smooth surfaces and reliable mounting during testing. This fabrication method supported quick turnaround between design changes and experimental evaluation.

Wind tunnel setup

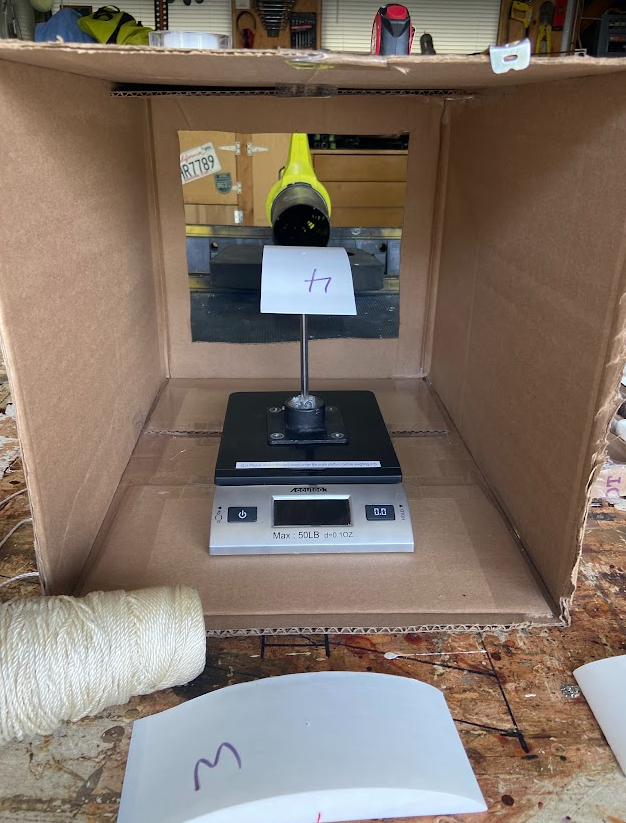

A makeshift wind tunnel was constructed using a leaf blower as the airflow source. The setup was designed to provide a steady, repeatable airflow across the airfoil while allowing access for instrumentation. Although not intended to produce absolute aerodynamic coefficients, the tunnel was sufficient for relative comparisons between airfoil shapes under similar flow conditions.

Instrumentation and data collection

Testing focused on measuring lift force and pressure differences across the airfoil surfaces. A scale-based setup was used to measure lift directly, while pressure gauges were used to record flow behavior on the top and bottom surfaces of the airfoil. Data was collected across multiple configurations to improve repeatability and reduce the impact of measurement noise.

Data analysis and theory comparison

Collected data was plotted and analyzed to compare relative lift trends between airfoil shapes. Experimental results were then compared against theoretical lift equations and expected aerodynamic behavior to evaluate agreement and identify sources of discrepancy. This comparison helped contextualize experimental limitations while reinforcing fundamental aerodynamic principles.

Results and takeaways

The project demonstrated clear performance differences between airfoil geometries and reinforced how shape influences lift and pressure distribution. While the experimental setup had inherent limitations, the results aligned with theoretical expectations in relative terms. The project strengthened practical intuition for aerodynamic testing, data interpretation, and the gap between idealized models and physical experiments.

Skills and engineering focus

This project developed skills in CAD-based aerodynamic design, rapid prototyping, experimental setup design, data collection, and analytical comparison to theory. It reflects an applied approach to aerodynamics, emphasizing iteration, measurement, and interpretation over purely analytical solutions.