Manual and CNC Machining Projects

Precision Manufacturing and Component Fabrication

Project overview

This collection documents hands-on manual and CNC machining projects focused on producing precision mechanical components from CAD models and engineering drawings. The work emphasizes machining fundamentals, design-for-manufacturing, and iterative improvement through physical fabrication. Projects span manual mill and lathe operations, CNC milling and turning, and supporting welding work, with an emphasis on dimensional accuracy, surface finish, and functional integration.

Project: Machined Screwdriver

Objective

Design and fabricate a functional hand tool emphasizing concentricity, ergonomics, and surface finish.

Manufacturing process

Manual lathe operations for shaft and handle geometry

CNC mill operations for feature machining and finishing

Key engineering considerations

Concentricity between handle and shaft

Surface finish for grip and usability

Tooling and setup sequencing

Validation

Dimensional inspection and functional use testing

Media

Project: Pressure Distribution Block

Objective

Manufacture a precision block with controlled hole placement and internal flow paths.

Manufacturing process

Manual milling and drilling operations

Layout and datum referencing for accurate feature placement

Key engineering considerations

Hole location tolerance and perpendicularity

Flatness and sealing surfaces

Machining order to maintain accuracy

Tapped holes for pressure hose barbs

Validation

Dimensional inspection and fit verification

Media

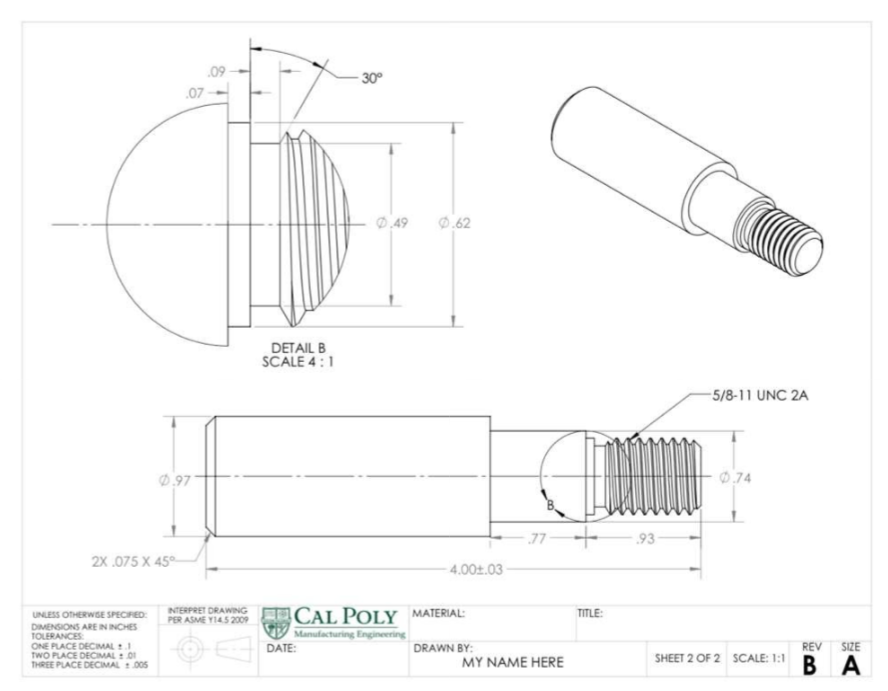

Project: Threaded Components

Objective

Produce threaded parts to specification for mechanical integration.

Manufacturing process

Manual lathe threading operations

CNC lathe exposure on Haas equipment

Key engineering considerations

Thread form accuracy and pitch control

Tool selection and cutting parameters

Fit with mating components

Validation

Thread gauges and functional fit testing

Media

Project: Custom Washers and Inserts

Objective

Fabricate tolerance-controlled washers and inserts for assembly applications.

Manufacturing process

Manual lathe and mill operations

CNC milling where repeatability was required

Key engineering considerations

Thickness tolerance and parallelism

Inner and outer diameter control

Batch consistency

Validation

Assembly fit checks and dimensional inspection

Manufacturing tools and capabilities

Manual mill and lathe (certified)

CNC milling on Haas Mini Mill

CNC lathe experience on Haas equipment

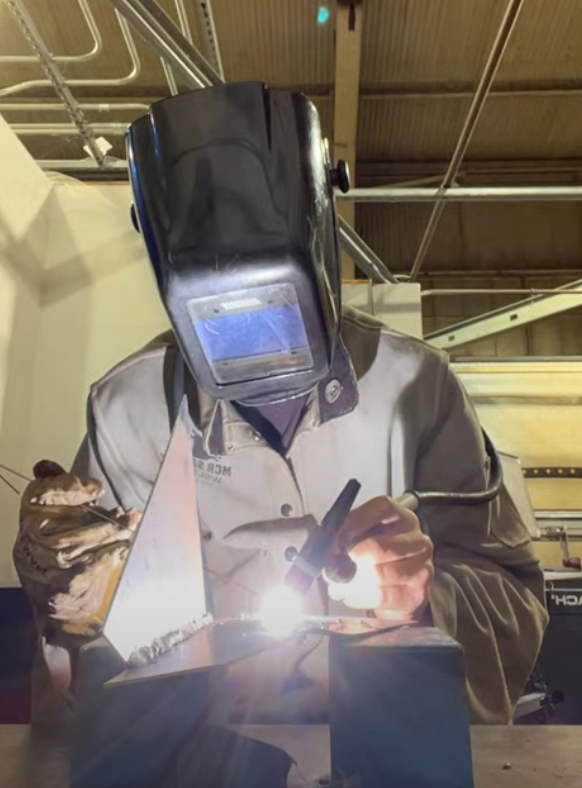

Welding for fixtures, repairs, and assemblies

Engineering practices

GD&T and dimensional tolerancing

Design for manufacturability

Process planning and setup sequencing

Iterative improvement based on physical feedback