Electronics Packaging | Vehicle Systems and Environmental Protection Project

System objective and operating environment

This project focused on the development of electronics packaging solutions for a Formula SAE vehicle operating in a highly dynamic motorsport environment characterized by sustained vibration, transient shock loads, elevated temperatures, and constrained packaging volume. The primary objective was to ensure reliable operation of critical electronic subsystems throughout competition events while minimizing mass and preserving serviceability. As Electronics Packaging Team Lead, I owned the end-to-end design process from requirements definition through fabrication and vehicle integration.

Structural enclosure design

Enclosure geometry and mounting architecture were designed to protect sensitive electronics from impact and chassis-induced loads while maintaining structural efficiency. Using Siemens NX, I developed enclosure designs that balanced stiffness, wall thickness, and internal ribbing to resist deformation under shock and vibration. Mounting interfaces were tailored to the vehicle chassis to distribute loads and reduce stress concentrations. Structural decisions were driven by both qualitative load reasoning and iterative physical validation rather than overbuilt solutions, keeping mass low without sacrificing robustness.

Vibration isolation and shock mitigation

Given the vibration-rich operating environment, particular emphasis was placed on isolating electronics from resonance and high-frequency excitation. I engineered isolation strategies that combined compliant mounting elements with controlled stiffness paths to attenuate harmful vibration while maintaining positional stability. Placement of electronics relative to chassis hard points was also optimized to reduce exposure to peak vibratory modes. These design choices improved electronics survivability and reduced intermittent faults associated with connector fatigue and sensor noise.

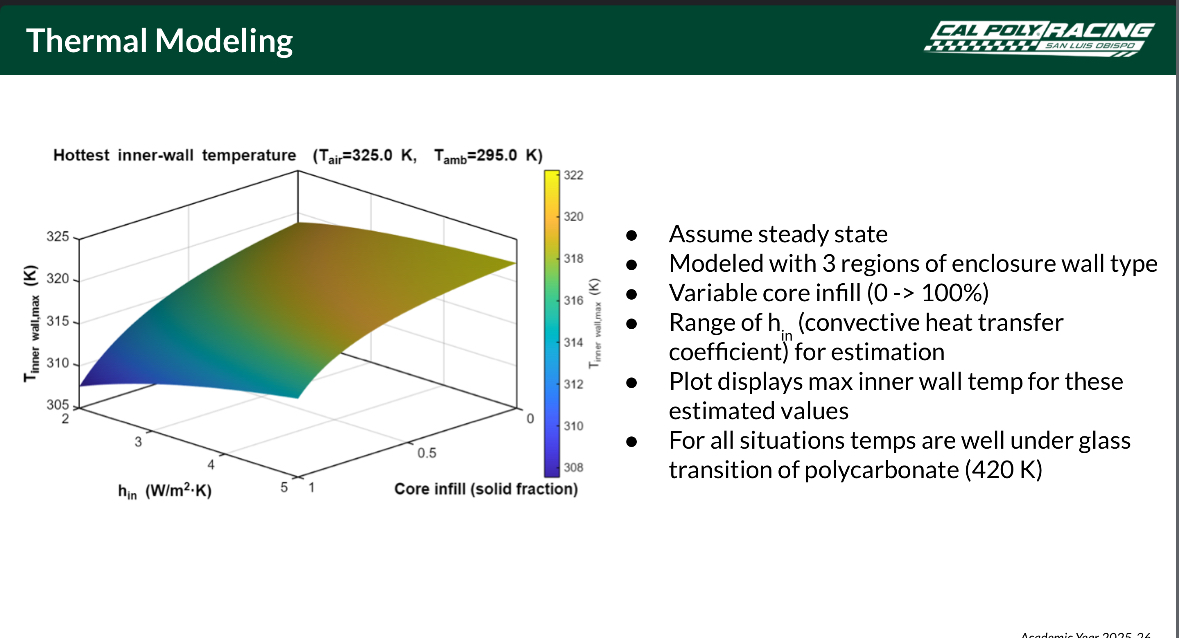

Thermal management and reliability

Thermal performance was a key design driver due to sustained electrical loads and limited airflow within enclosed vehicle volumes. I evaluated heat transfer behavior to inform enclosure venting, material selection, and internal component spacing. Designs were refined to promote passive heat dissipation while avoiding direct exposure of electronics to debris or moisture. This ensured stable operating temperatures across race conditions and reduced the risk of thermal derating or component failure.

Manufacturing and rapid iteration

Manufacturing strategy prioritized rapid iteration, dimensional accuracy, and durability. Enclosures were produced using advanced FDM 3D printing with carbon-reinforced nylon and polycarbonate, providing a strong balance between mechanical strength, temperature resistance, and lead time. This approach enabled fast design cycles and real-world testing feedback to be incorporated without delaying vehicle integration. Print orientation, wall thickness, and fastener interfaces were refined to improve strength and repeatability.

Integration and serviceability

Electronics packaging was designed with full vehicle integration in mind. Enclosures incorporated strain relief features, cable routing considerations, and service access to allow rapid installation and maintenance during competition. Close collaboration with other subsystem leads ensured compatibility with electrical, mechanical, and thermal requirements across the vehicle. This systems-level coordination reduced integration friction and improved overall vehicle reliability.

Validation and performance outcome

Designs were validated through vehicle operation in competition-like conditions, where enclosures demonstrated improved durability, thermal stability, and resistance to vibration-induced failures. Iterative refinement based on real-world use resulted in packaging solutions that directly supported system uptime and vehicle performance. The project reflects practical experience in designing protective electronics packaging under real constraints, with direct relevance to aerospace, automotive, and defense vehicle systems engineering.